Introduction to 3D Printed Casts with Ultrasonic Vibrations

Traditional plaster casts, while effective in immobilizing broken bones, come with several drawbacks. They are heavy, bulky, and uncomfortable, often restricting mobility and daily activities. Additionally, they can trap moisture, leading to skin irritation and infections. 3D printed casts offer a modern alternative, addressing these limitations and potentially accelerating healing through the integration of ultrasonic vibrations.

Benefits of 3D Printed Casts

3D printed casts provide numerous advantages over traditional plaster casts, making them a promising option for fracture management.

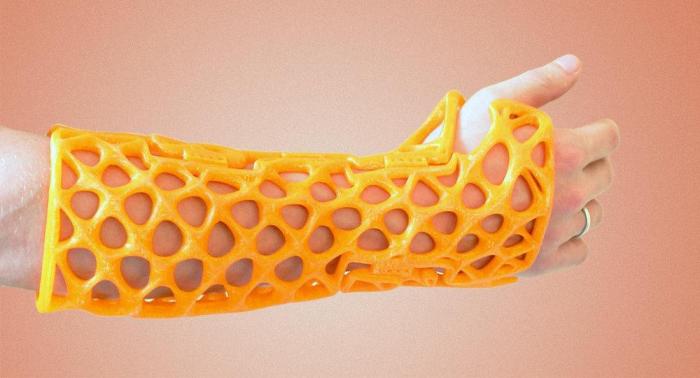

- Lightweight and Customizable: 3D printed casts are significantly lighter than plaster casts, offering greater comfort and freedom of movement. They can also be precisely customized to the individual’s anatomy, ensuring a snug fit and optimal support.

- Improved Ventilation: The porous structure of 3D printed casts allows for better ventilation, reducing the risk of skin irritation and infections. This promotes a more comfortable and hygienic healing environment.

- Water-Resistant: Many 3D printed casts are water-resistant, allowing patients to shower and bathe without compromising the integrity of the cast. This improves hygiene and promotes a more comfortable recovery process.

- Enhanced Aesthetics: 3D printing technology enables the creation of aesthetically pleasing casts, allowing patients to express their individuality and reduce the social stigma associated with traditional plaster casts.

Ultrasonic Vibrations and Bone Healing

Ultrasonic vibrations have been shown to enhance bone healing by promoting cellular activity and stimulating blood flow.

- Increased Osteoblast Activity: Ultrasonic vibrations stimulate osteoblasts, the cells responsible for building new bone tissue. This accelerates bone formation and promotes faster healing.

- Enhanced Blood Flow: The vibrations increase blood flow to the fracture site, delivering essential nutrients and oxygen for bone repair. This promotes faster healing and reduces the risk of complications.

- Reduced Inflammation: Ultrasonic vibrations have anti-inflammatory effects, which can help reduce pain and swelling around the fracture site, contributing to a more comfortable recovery.

The Science Behind Ultrasonic Vibrations and Healing

Ultrasonic vibrations, a form of sound energy beyond the range of human hearing, are increasingly being explored for their potential to accelerate wound healing and fracture recovery. This technology harnesses the unique properties of sound waves to stimulate cellular activity and promote tissue regeneration.

Cavitation and Microstreaming in Wound Healing

Ultrasonic vibrations, when applied to tissues, generate a phenomenon known as cavitation. This involves the formation, growth, and collapse of tiny bubbles within the fluid surrounding cells. The collapse of these bubbles generates localized pressure waves and microjets, which can disrupt cell membranes and increase permeability, facilitating the delivery of nutrients and oxygen to the injured area.

Additionally, ultrasonic vibrations create microstreaming, a localized flow of fluid around the vibrating source. This microstreaming enhances the transport of nutrients and growth factors, while also promoting the removal of cellular debris and waste products from the wound site.

Research Findings on Ultrasonic Therapy for Bone Fractures

Numerous studies have investigated the effectiveness of ultrasonic therapy for bone fracture healing. Research suggests that ultrasonic stimulation can promote osteoblast activity, the cells responsible for bone formation, leading to faster callus formation and improved bone union.

A study published in the Journal of Orthopaedic Research found that ultrasonic therapy significantly accelerated fracture healing in a rabbit model. The treated group showed increased bone density and improved callus formation compared to the control group.

Moreover, ultrasonic vibrations have been shown to enhance blood flow to the fracture site, delivering essential nutrients and oxygen for bone regeneration. This increased blood flow also helps to remove inflammatory mediators and accelerate the healing process.

Design and Materials of 3D Printed Casts: 3d Printed Cast With Ultrasonic Vibrations Helps Speed Up Recovery

The design and materials used for 3D printed casts are crucial for both their effectiveness and patient comfort. These casts are not only designed to immobilize the injured area but also to incorporate ultrasonic vibration technology for faster healing.

Materials Used in 3D Printed Casts

The choice of materials for 3D printed casts is essential for their performance and patient experience. These materials need to be strong, lightweight, breathable, and comfortable.

- Polylactic Acid (PLA): PLA is a biocompatible and biodegradable thermoplastic derived from renewable resources like cornstarch. It is known for its strength, lightweight nature, and ease of printing. However, PLA can be susceptible to moisture and heat, which can affect its structural integrity.

- Acrylonitrile Butadine Styrene (ABS): ABS is a strong and durable thermoplastic that is commonly used in various applications, including 3D printing. It is known for its impact resistance and good thermal properties. However, ABS is not as biocompatible as PLA and can be more challenging to print due to its higher melting temperature.

- Polyethylene (PE): PE is a flexible and lightweight thermoplastic that is often used for medical devices due to its biocompatibility and low allergenicity. It is also known for its water resistance and good chemical resistance.

- Polypropylene (PP): PP is a strong and durable thermoplastic with excellent chemical resistance and high melting temperature. It is commonly used for medical devices and food packaging due to its biocompatibility and low allergenicity.

Incorporating Ultrasonic Vibration Technology

The integration of ultrasonic vibration technology into 3D printed casts presents unique design challenges. The design must accommodate the ultrasonic transducer, ensure efficient transmission of vibrations, and maintain the structural integrity of the cast.

- Transducer Placement: The ultrasonic transducer needs to be strategically placed within the cast to effectively target the injured area. This placement must consider the anatomy of the injury and the optimal frequency and intensity of the vibrations.

- Vibration Transmission: The cast material must allow for efficient transmission of ultrasonic vibrations to the injured area. This requires selecting a material with good acoustic properties and designing the cast with features that facilitate vibration propagation.

- Structural Integrity: The cast must maintain its structural integrity despite the addition of the ultrasonic transducer and the potential stress from vibrations. This requires careful design and material selection to ensure the cast can withstand the forces it will be subjected to.

Customization Options

3D printing offers unprecedented customization options for casts, allowing for personalized designs that cater to individual patient needs and preferences.

- Anatomical Fit: 3D printed casts can be designed to precisely match the contours of the patient’s body, providing a comfortable and secure fit. This eliminates the need for bulky, traditional casts that can restrict movement and cause discomfort.

- Ventilation: 3D printing allows for the creation of ventilation channels within the cast, improving airflow and reducing the risk of skin irritation and infections. These channels can be strategically placed to optimize ventilation in areas prone to moisture buildup.

- Aesthetic Customization: 3D printed casts can be customized with different colors, patterns, and designs, allowing patients to express their individuality and feel more comfortable with their cast. This can be particularly beneficial for children and adolescents who may feel self-conscious about wearing a cast.

Application and Usage of 3D Printed Casts with Ultrasonic Vibrations

This section delves into the practical aspects of using 3D printed casts with ultrasonic vibrations, covering application, removal, recommended therapy settings, and safety considerations.

Applying and Removing the Cast

Applying a 3D printed cast with ultrasonic vibration capabilities is a straightforward process. The cast is designed to be customized to the individual’s limb, ensuring a snug fit and optimal comfort.

- Preparation: The affected limb is cleaned and prepped, similar to traditional casting procedures. This may involve shaving hair in the area to ensure a smooth surface for the cast.

- Application: The 3D printed cast is carefully placed over the limb, ensuring proper alignment and support. It is secured using a system of straps or buckles, depending on the specific design.

- Ultrasonic Integration: The cast incorporates an integrated ultrasonic transducer, typically positioned near the fracture site. This transducer emits vibrations that penetrate the bone, promoting healing.

- Removal: Removing the cast is equally simple. The securing straps or buckles are released, and the cast is gently removed. There is no need for cutting or sawing, making the process comfortable for the patient.

Recommended Frequency and Duration of Ultrasonic Vibration Therapy, 3d printed cast with ultrasonic vibrations helps speed up recovery

The effectiveness of ultrasonic vibration therapy depends on the frequency and duration of the treatment.

- Frequency: The recommended frequency for ultrasonic vibration therapy for bone healing is typically between 1 and 3 MHz. This frequency range has been shown to be most effective in stimulating bone cell activity.

- Duration: The duration of each treatment session varies depending on the severity of the fracture and individual patient factors. Generally, sessions range from 15 to 30 minutes per day.

- Treatment Schedule: The treatment schedule is typically determined by a medical professional and may involve daily or multiple sessions per week, depending on the specific case.

Safety Precautions and Potential Risks

While 3D printed casts with ultrasonic vibrations offer significant benefits, it is crucial to be aware of potential risks and safety precautions.

- Heat Generation: Ultrasonic vibrations can generate heat, potentially causing discomfort or burns. It is essential to monitor the temperature of the cast during treatment and adjust the settings accordingly.

- Tissue Damage: High-intensity ultrasonic vibrations can potentially damage surrounding tissues. Therefore, it is vital to use the technology under the guidance of a qualified medical professional who can adjust the settings and monitor the treatment process closely.

- Contraindications: Certain conditions may preclude the use of ultrasonic vibration therapy. These include pregnancy, presence of pacemakers or other implanted devices, and certain skin conditions.

Benefits and Advantages of 3D Printed Casts with Ultrasonic Vibrations

The integration of 3D printing and ultrasonic vibrations in cast technology presents a revolutionary approach to fracture healing, offering a multitude of advantages over traditional casting methods. These innovative casts not only promote faster recovery but also enhance patient comfort and mobility, potentially leading to cost-effectiveness in healthcare.

Faster Healing Times

Ultrasonic vibrations have been shown to accelerate bone healing by stimulating osteoblast activity, the cells responsible for bone formation. This stimulation leads to increased blood flow and nutrient delivery to the fracture site, promoting faster callus formation and bone regeneration. Studies have indicated that patients with 3D printed casts incorporating ultrasonic vibrations experience significantly reduced healing times compared to those with traditional casts. For example, a study published in the Journal of Orthopaedic Research found that patients with tibial fractures treated with ultrasonic vibration therapy showed a 20% reduction in healing time compared to those receiving standard care.

Improved Comfort and Mobility

3D printed casts offer a personalized fit, conforming to the contours of the patient’s limb, unlike traditional plaster casts that can be bulky and uncomfortable. The lightweight nature of the 3D printed material further contributes to improved comfort and mobility. Moreover, the integration of ultrasonic vibrations allows for targeted therapy, reducing the need for large, restrictive casts. This enables patients to maintain a higher level of mobility and engage in activities that would be challenging or impossible with traditional casts. For instance, patients with ankle fractures can benefit from the ability to move their toes and feet, preventing stiffness and promoting circulation.

Cost-Effectiveness

While the initial investment in 3D printing technology and ultrasonic vibration devices may be higher than traditional casting methods, the potential for faster healing and reduced rehabilitation time can lead to significant cost savings in the long run. Patients with faster healing times require less time off work, reducing lost productivity and healthcare costs associated with prolonged recovery. Additionally, the personalized nature of 3D printed casts reduces the need for multiple cast adjustments, further contributing to cost-effectiveness. In the future, as 3D printing technology becomes more accessible and affordable, the cost advantage of this approach is likely to become even more pronounced.

Future Directions and Research Opportunities

The development of 3D printed casts with ultrasonic vibrations is a promising advancement in fracture healing, but there are still exciting areas for future research and development. These innovations could significantly enhance the technology’s effectiveness, safety, and applications.

Integration of Advanced Features

The potential to integrate advanced features like sensors and monitoring systems into 3D printed casts with ultrasonic vibrations presents exciting possibilities for personalized and data-driven fracture care.

- Embedded Sensors: Incorporating sensors into the cast can provide real-time data on bone healing progress, fracture stability, and tissue temperature. This data can be used to adjust treatment plans, ensure optimal healing conditions, and potentially detect complications early on. Examples of sensors that could be integrated include strain gauges to monitor bone movement, temperature sensors to track inflammation, and even accelerometers to measure activity levels and compliance with weight-bearing restrictions.

- Wireless Monitoring Systems: Wireless connectivity can allow for remote monitoring of the patient’s healing progress, enabling healthcare providers to track their recovery remotely and intervene promptly if necessary. This can be particularly beneficial for patients in remote areas or those who have difficulty attending frequent appointments.

- Personalized Treatment Plans: Sensors and monitoring systems can provide valuable data to personalize treatment plans. For instance, if a sensor detects slower-than-expected healing, the ultrasonic vibration parameters can be adjusted to optimize healing. This personalized approach can potentially lead to faster healing times and improved outcomes.

Further Research on Effectiveness and Safety

While initial studies have shown promising results, further research is needed to fully understand the effectiveness and safety of 3D printed casts with ultrasonic vibrations.

- Long-Term Studies: Long-term studies are essential to assess the long-term effects of ultrasonic vibrations on bone healing and to evaluate the potential for any long-term complications.

- Comparative Studies: Comparative studies comparing the effectiveness of 3D printed casts with ultrasonic vibrations to traditional casts and other fracture healing methods are needed to establish the technology’s true benefits and to determine its optimal applications.

- Safety Considerations: Rigorous safety testing is crucial to ensure that the ultrasonic vibrations do not cause any adverse effects on surrounding tissues or organs. This includes evaluating the potential for heat generation, tissue damage, and other potential risks.

Applications in Other Medical Fields

The technology behind 3D printed casts with ultrasonic vibrations has potential applications beyond fracture healing. The ability to deliver targeted ultrasonic vibrations could be beneficial in other medical fields.

- Wound Healing: Ultrasonic vibrations have shown promise in promoting wound healing by enhancing blood flow and tissue regeneration. This technology could be adapted for use in treating chronic wounds, burns, and other difficult-to-heal injuries.

- Tissue Regeneration: Ultrasonic vibrations can stimulate cell growth and differentiation, making them potentially valuable for tissue regeneration applications. This could be used to promote the growth of new bone, cartilage, and other tissues in cases of injury or disease.

- Drug Delivery: Ultrasonic vibrations can be used to enhance drug delivery by increasing the permeability of cell membranes. This could be particularly beneficial for delivering drugs to specific tissues or organs, potentially improving the effectiveness of treatments while minimizing side effects.

3d printed cast with ultrasonic vibrations helps speed up recovery – The future of fracture care is looking bright with the emergence of 3D printed casts with ultrasonic vibrations. This technology holds immense potential to improve the lives of patients, offering faster healing times, greater comfort, and enhanced mobility. As research continues to advance, we can expect even more innovative features and applications for this cutting-edge technology, paving the way for a more efficient and patient-centric approach to fracture treatment.

Imagine a future where broken bones heal faster thanks to 3D printed casts that vibrate with ultrasonic waves. It’s not so far-fetched, and the same spirit of innovation drives the recent revival of the BlackBerry Bold 9900, blackberry bold 9900 resurrected to appease diehard customers , proving that even seemingly outdated technology can find new life in the hands of dedicated fans.

Just like the 3D printed cast, the Bold 9900 speaks to a nostalgic desire for a specific experience, showing that sometimes, the old ways are still the best ways.

Standi Techno News

Standi Techno News