Collaborative robotics is prioritizing human problem solving over humanoid forms, marking a shift in the way we think about robots. Gone are the days of robots striving to mimic human form. Instead, the focus is on creating machines that work alongside humans, enhancing their abilities and solving complex problems together.

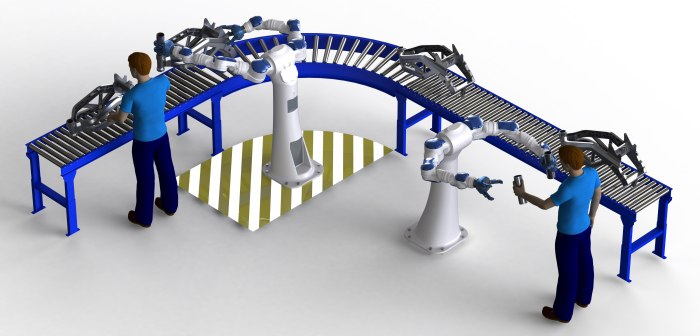

This evolution has given rise to collaborative robots, or cobots, designed to seamlessly integrate into human workspaces. Cobots are not replacements for human workers, but rather partners, assisting in tasks that require precision, repetition, or heavy lifting. They are equipped with advanced safety features, allowing them to operate alongside humans without posing a threat.

The Shift from Humanoid Form to Human Problem Solving

The history of robotics is marked by a fascinating evolution, from the initial ambition of creating machines that mirrored human form to a more pragmatic approach that prioritizes collaboration and problem-solving. Early robotics focused on mimicking human movement and dexterity, driven by the desire to create machines capable of performing tasks that were too dangerous or repetitive for humans. This pursuit led to the development of humanoid robots, often depicted in science fiction as companions or assistants.

However, the practical limitations of replicating human anatomy and the complexity of achieving true human-level intelligence became increasingly apparent. The shift towards collaborative robotics emerged from the realization that robots could be far more effective by focusing on specific tasks and working alongside humans. This approach emphasizes the complementary strengths of both humans and robots, leveraging human ingenuity and problem-solving abilities with the precision and endurance of robotic systems.

Collaborative Robots in Action

The focus on human-robot collaboration has led to the development of more adaptable and flexible robotic systems known as cobots. Cobots are designed to work safely and efficiently alongside humans, performing tasks that require dexterity, precision, or repetitive motion. Their collaborative nature allows them to learn from human feedback, adapt to changing environments, and enhance overall productivity.

Here are some examples of cobots in various industries:

- Manufacturing: Cobots are increasingly used in assembly lines, performing tasks such as picking and placing components, welding, and quality inspection. Their ability to work alongside humans allows for greater flexibility and adaptability in production processes.

- Healthcare: Cobots are employed in hospitals and clinics to assist with tasks such as patient care, medication dispensing, and surgical procedures. Their precision and accuracy can improve the efficiency and safety of medical procedures.

- Agriculture: Cobots are used in farming to automate tasks like harvesting, planting, and spraying. Their ability to operate in challenging environments and perform repetitive tasks can enhance productivity and reduce labor costs.

The Benefits of Collaborative Robotics

The rise of collaborative robotics offers numerous benefits for businesses and individuals:

- Enhanced Productivity: Cobots can automate repetitive tasks, freeing up human workers to focus on more complex and creative tasks.

- Improved Safety: Cobots are designed to work safely alongside humans, reducing the risk of workplace injuries.

- Increased Flexibility: Cobots can be easily reprogrammed to perform different tasks, making them adaptable to changing production needs.

- Reduced Costs: Cobots can help businesses reduce labor costs and increase efficiency.

Benefits of Collaborative Robotics for Human Problem Solving

Collaborative robots, or cobots, are designed to work alongside humans, offering a unique advantage in enhancing problem-solving capabilities. Cobots can augment human skills, improve efficiency, and create safer work environments, leading to innovative solutions and increased productivity across various industries.

Cobots as Tools for Enhanced Dexterity and Precision

Cobots can be programmed to perform tasks with a level of dexterity and precision that surpasses human capabilities. They can handle delicate components, assemble intricate products, and perform intricate surgical procedures with accuracy and repeatability. This frees up human workers to focus on tasks requiring higher-level cognitive skills, such as problem-solving, decision-making, and creative design.

Cobots for Repetitive Tasks and Increased Productivity

Cobots excel at performing repetitive tasks with unwavering consistency, reducing human fatigue and errors. They can handle tasks such as packaging, welding, and painting, freeing up human workers to focus on more complex and engaging activities. This shift in workload not only increases productivity but also improves worker satisfaction and reduces the risk of repetitive strain injuries.

Cobots for Worker Safety and Improved Efficiency

Cobots are designed with safety features that minimize the risk of accidents. They can work in hazardous environments, such as handling heavy objects, working in confined spaces, or operating in areas with high noise levels. This allows humans to avoid exposure to these risks, improving worker safety and well-being. Furthermore, cobots can be deployed in remote locations, minimizing the need for human intervention and reducing the risks associated with dangerous tasks.

Examples of Cobots in Action

- In the automotive industry, cobots assist with assembly line tasks, such as welding, painting, and component installation. This allows human workers to focus on quality control and troubleshooting, while cobots handle repetitive and physically demanding tasks.

- In healthcare, cobots are used for surgical assistance, drug dispensing, and patient rehabilitation. They provide surgeons with greater precision and dexterity, while also reducing the risk of human error in complex procedures.

- In manufacturing, cobots are deployed for tasks such as material handling, machine tending, and quality inspection. This allows human workers to focus on higher-level tasks, such as process optimization and problem-solving, while cobots handle the more mundane and repetitive tasks.

Impact on Productivity and Efficiency

The integration of cobots in the workplace has a significant impact on productivity and efficiency. Studies have shown that cobots can increase production rates by up to 30%, reduce error rates by up to 85%, and shorten lead times by up to 50%. This translates to faster turnaround times, higher output, and lower production costs, making businesses more competitive in the global marketplace.

The Future of Human-Robot Collaboration

As collaborative robotics technology continues to advance, we can expect to see even more innovative applications in various industries. Cobots will become increasingly sophisticated, capable of performing even more complex tasks and working alongside humans in a wider range of environments. This will lead to a future where humans and robots work together seamlessly, leveraging their respective strengths to solve complex problems and drive innovation.

Key Features of Collaborative Robots

Collaborative robots, also known as cobots, are a new breed of robots designed to work alongside humans in a shared workspace. Unlike traditional industrial robots that operate behind safety cages, cobots are built with safety features that allow them to interact with humans directly. This opens up new possibilities for automation in various industries, from manufacturing to healthcare.

Cobots possess a unique set of features that distinguish them from their industrial counterparts. These features are crucial for enabling safe and efficient human-robot collaboration.

Safety Features

Safety is paramount in collaborative robotics. Cobots are equipped with a range of features that minimize the risk of injury to human workers.

- Force Limiting: Cobots are designed with sensors that detect contact with humans and limit the force exerted by the robot’s joints. This prevents the robot from causing harm even in the event of a collision.

- Collaborative Workspace Design: The workspace where cobots operate is designed to ensure safe human interaction. This may involve using soft materials, rounded edges, and appropriate lighting to reduce potential hazards.

- Human-Robot Interaction Technologies: Cobots often utilize advanced technologies to communicate with humans and ensure safe interaction. These technologies include:

- Vision Systems: Cameras and sensors allow cobots to perceive their surroundings and detect human presence. This enables them to adjust their movements to avoid collisions.

- Safety Controllers: These controllers monitor the robot’s movements and stop the robot if a potential hazard is detected.

- Human-Robot Collaboration Interfaces: These interfaces allow humans to easily communicate with the robot and provide instructions.

Sensors and Vision Systems

Sensors and vision systems play a vital role in enabling cobots to work safely alongside humans.

- Sensors: Cobots are equipped with a variety of sensors that provide them with information about their surroundings. These sensors include:

- Force Sensors: These sensors measure the force applied by the robot’s joints, allowing the robot to detect contact with humans and adjust its movements accordingly.

- Proximity Sensors: These sensors detect objects in the robot’s vicinity, enabling it to avoid collisions with humans or other obstacles.

- Temperature Sensors: These sensors monitor the temperature of the robot’s components, ensuring safe operation.

- Vision Systems: Cameras and image processing algorithms allow cobots to perceive their surroundings and recognize objects and humans. This enables them to:

- Navigate their workspace safely: Vision systems allow cobots to identify obstacles and adjust their movements accordingly.

- Identify and track objects: Cobots can use vision systems to identify and track objects of interest, such as parts on a conveyor belt.

- Recognize human gestures: Some cobots are equipped with vision systems that can recognize human gestures, allowing them to respond to human instructions.

Advanced Programming

Cobots are programmed using advanced software that enables them to perform complex tasks and interact with humans safely.

- User-Friendly Programming Interfaces: Cobots often utilize user-friendly programming interfaces that allow users with limited programming experience to easily program the robot.

- Adaptive Control Algorithms: Cobots use adaptive control algorithms that allow them to adjust their movements based on real-time data from sensors and vision systems. This enables them to adapt to changing conditions and work safely alongside humans.

- Machine Learning: Some cobots use machine learning algorithms to learn from experience and improve their performance over time. This allows them to adapt to new tasks and work more efficiently.

Real-World Applications of Collaborative Robotics

Collaborative robots, also known as cobots, are revolutionizing various industries by working alongside humans to automate tasks, improve efficiency, and enhance human capabilities. Cobots are designed with safety features that allow them to operate in close proximity to humans without posing any risks. They are versatile and can be easily programmed to perform a wide range of tasks, making them ideal for various applications across different industries.

Applications of Collaborative Robots in Various Industries

Collaborative robots are being implemented across a wide range of industries, including manufacturing, healthcare, agriculture, and logistics. Here’s a glimpse of how cobots are making a difference in these sectors:

| Industry | Specific Application | Benefits of Using Cobots |

|---|---|---|

| Manufacturing | Assembly line operations, material handling, quality control, and machine tending | Increased productivity, reduced labor costs, improved accuracy and consistency, and enhanced worker safety. |

| Healthcare | Surgical assistance, medication dispensing, patient care, and rehabilitation | Improved precision in surgical procedures, reduced risk of human error, enhanced patient safety, and increased efficiency in healthcare operations. |

| Agriculture | Planting, harvesting, packaging, and data collection | Increased yield, reduced labor costs, improved efficiency in agricultural processes, and enhanced data-driven decision-making. |

| Logistics | Order fulfillment, warehouse picking and packing, and delivery | Improved efficiency in logistics operations, reduced labor costs, enhanced accuracy in order fulfillment, and increased speed of delivery. |

Challenges and Future Directions: Collaborative Robotics Is Prioritizing Human Problem Solving Over Humanoid Forms

While collaborative robotics holds immense promise, its widespread adoption faces certain challenges and limitations. Addressing these concerns and exploring future directions will be crucial for realizing the full potential of cobots in various industries.

Ethical Concerns

The integration of cobots into the workplace raises ethical concerns, primarily related to job displacement and worker training.

- Job Displacement: One major concern is the potential for cobots to replace human workers, leading to job losses. While cobots are designed to augment human capabilities rather than replace them entirely, it’s essential to address the potential economic and social implications of job displacement.

- Worker Training: The successful implementation of cobots requires adequate training for workers to interact and collaborate with them effectively. This training should include safety protocols, operational procedures, and troubleshooting skills to ensure a smooth transition and minimize risks.

Future Directions, Collaborative robotics is prioritizing human problem solving over humanoid forms

Collaborative robotics research and development are continuously evolving, driven by advancements in artificial intelligence (AI) and human-robot interaction (HRI).

- AI Integration: Integrating AI into cobots will enable them to perform more complex tasks, learn from experience, and adapt to changing environments. This includes developing advanced perception, decision-making, and learning capabilities, enhancing the overall intelligence and autonomy of cobots.

- Advanced HRI Systems: Enhancing HRI systems is crucial for seamless human-robot collaboration. This involves developing intuitive interfaces, natural language processing capabilities, and gesture recognition technologies to enable more natural and efficient communication between humans and cobots.

The rise of collaborative robotics signifies a future where humans and machines work in harmony. Cobots are not just tools; they are collaborators, amplifying human capabilities and pushing the boundaries of problem-solving. As technology continues to evolve, we can expect to see even more innovative applications of cobots across industries, leading to greater efficiency, productivity, and a safer work environment for all.

Forget about robots that look like humans. Collaborative robotics is all about building machines that work *with* us, not *for* us. This shift in focus is evident in Tim Cook’s recent announcement that Apple will be making major strides in AI this year. tim cook says apple will break new ground in genai this year. This means we can expect to see more AI-powered tools that augment our abilities, making us smarter and more efficient, rather than replacing us altogether.

Standi Techno News

Standi Techno News