Arduino India Manufacturing: It’s not just a buzzword, it’s a revolution brewing in the heart of India. Imagine a world where manufacturing is no longer a complex, expensive, and time-consuming process. That’s the vision Arduino brings to the table, and it’s making waves across Indian industries.

From automation to prototyping, Arduino is empowering Indian manufacturers to innovate, optimize, and create a future where technology and ingenuity go hand in hand.

Arduino’s Role in Indian Manufacturing: Arduino India Manufacturing

Arduino, the open-source electronics platform, has emerged as a powerful tool for Indian manufacturers, enabling them to embrace automation, streamline prototyping, and drive innovation across various industries. Its accessibility, affordability, and ease of use have made it a popular choice for businesses of all sizes.

Impact of Arduino on Indian Manufacturing

Arduino’s impact on Indian manufacturing is multifaceted, spanning automation, prototyping, and innovation.

- Automation: Arduino enables manufacturers to automate repetitive tasks, freeing up human resources for more complex and value-adding activities. This is particularly relevant in industries like packaging, assembly, and material handling.

- Prototyping: Arduino’s rapid prototyping capabilities allow manufacturers to quickly test and refine new product designs and processes. This agility helps reduce development time and costs, allowing businesses to bring innovative products to market faster.

- Innovation: Arduino’s open-source nature fosters a culture of collaboration and experimentation, encouraging manufacturers to develop unique solutions for their specific needs. This leads to the creation of innovative products and processes that improve efficiency and competitiveness.

Industries Leveraging Arduino Technology

Arduino is finding applications in a wide range of industries in India, contributing to their growth and modernization.

- Agriculture: Arduino-powered sensors are used to monitor soil moisture, temperature, and other environmental factors, optimizing irrigation and crop yields.

- Textile Industry: Arduino is used to automate textile machinery, improve production efficiency, and enhance quality control.

- Automotive Industry: Arduino is used in automotive testing and development, facilitating the creation of intelligent and connected vehicles.

- Healthcare Industry: Arduino is used to develop medical devices and systems, enabling remote patient monitoring and improving healthcare accessibility.

- Renewable Energy: Arduino is used to design and control solar and wind energy systems, contributing to India’s renewable energy goals.

Advantages and Challenges of Using Arduino in Indian Manufacturing

While Arduino offers numerous advantages for Indian manufacturers, it’s crucial to acknowledge the challenges associated with its adoption.

Advantages

- Cost-Effectiveness: Arduino is relatively inexpensive compared to traditional industrial automation systems, making it accessible to small and medium-sized enterprises (SMEs).

- Ease of Use: Arduino’s user-friendly interface and extensive online community support make it easy for engineers and technicians with limited programming experience to learn and use.

- Flexibility: Arduino’s modular design allows manufacturers to customize systems to meet specific requirements and adapt to changing needs.

- Open-Source Nature: The open-source nature of Arduino fosters collaboration and innovation, enabling manufacturers to share knowledge and develop solutions together.

Challenges

- Reliability: Arduino’s low-cost components may have limited reliability in harsh industrial environments.

- Scalability: Scaling up Arduino-based systems for large-scale manufacturing operations can be challenging.

- Security: Security concerns may arise in interconnected systems, especially when sensitive data is involved.

- Skill Gap: A lack of skilled personnel in Arduino programming and implementation can hinder its effective adoption.

The Indian Arduino Ecosystem

The Arduino ecosystem in India is thriving, with a growing community of makers, hobbyists, students, and professionals embracing the platform for its ease of use, affordability, and vast potential. From the availability of components to support resources and community engagement, India’s Arduino ecosystem is fostering innovation and empowering individuals to build and create.

Components and Availability

The availability of Arduino components is a cornerstone of the ecosystem’s success. Numerous online and offline retailers cater to the needs of Arduino enthusiasts across India. Popular online marketplaces like Amazon India, Flipkart, and Snapdeal offer a wide range of Arduino boards, modules, sensors, and accessories. Local electronics stores and distributors also play a crucial role in supplying components to makers in different regions.

Support Resources and Community Engagement

The Indian Arduino community is vibrant and supportive, offering a wealth of resources for learners and developers. Online forums like the Arduino Project Hub and the Arduino India Forum serve as platforms for knowledge sharing, troubleshooting, and collaboration. Several online courses and tutorials are available on platforms like Udemy, Coursera, and Skillshare, providing structured learning paths for beginners and experienced users.

Key Players and Organizations, Arduino india manufacturing

Several organizations and initiatives are driving the adoption of Arduino in India. The Arduino India Community is a dedicated group that organizes workshops, hackathons, and meetups to promote Arduino’s use in various sectors. Educational institutions are increasingly integrating Arduino into their curriculum, exposing students to hands-on learning experiences in electronics and programming. Government initiatives like the Make in India program are also encouraging the use of open-source technologies like Arduino for manufacturing and innovation.

Arduino-Based Manufacturing Solutions in India

India’s manufacturing sector is undergoing a rapid transformation, embracing automation and digital technologies to enhance efficiency and productivity. Arduino, with its open-source platform and affordability, has emerged as a valuable tool for Indian manufacturers, enabling them to implement innovative and cost-effective solutions across various manufacturing processes.

Arduino Applications in Indian Manufacturing

Arduino’s versatility and accessibility have made it a popular choice for a wide range of manufacturing applications in India. Here are some examples of successful Arduino-based projects:

- Smart Factories: Indian manufacturers are increasingly adopting Industry 4.0 principles, leveraging Arduino for tasks like real-time data acquisition, process monitoring, and remote control of machinery. This enables better decision-making, optimized production lines, and reduced downtime. For example, a textile mill in Ahmedabad uses Arduino to monitor and control the temperature and humidity of its spinning machines, ensuring optimal yarn quality and minimizing production errors.

- Quality Control: Arduino-based systems can be used to automate quality checks, ensuring consistency and reducing human error. For instance, a pharmaceutical company in Hyderabad utilizes an Arduino-powered vision system to inspect pill shapes and sizes, rejecting any defective units before packaging.

- Process Monitoring: Arduino’s capabilities in data logging and analysis allow for real-time monitoring of critical manufacturing processes. This helps identify potential issues early, preventing costly downtime and production delays. A Mumbai-based automotive component manufacturer employs an Arduino-based system to monitor the temperature and pressure of its forging presses, ensuring optimal operating conditions and preventing equipment failure.

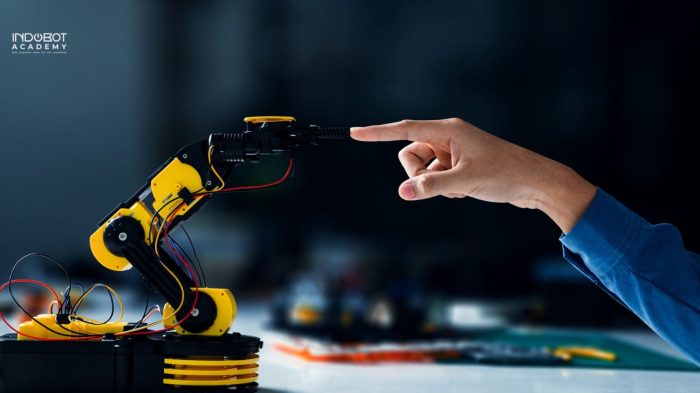

- Robotics and Automation: Arduino can be used to control and program robotic arms for tasks such as material handling, welding, and assembly. This reduces labor costs, improves efficiency, and enhances safety in manufacturing environments. A Chennai-based electronics manufacturer uses Arduino to control a robotic arm for automated PCB assembly, increasing production speed and accuracy.

Arduino-Based Solutions for Manufacturing Challenges

Arduino’s flexibility allows it to be tailored to address specific challenges faced by Indian manufacturers. Here’s a hypothetical example:

Challenge: A small-scale garment factory in Bangalore faces difficulties in maintaining consistent fabric quality due to variations in humidity and temperature.

Solution: An Arduino-based system can be designed to monitor the humidity and temperature levels in the factory’s cutting and sewing areas. This system can then be used to automatically adjust the air conditioning system to maintain optimal environmental conditions. Additionally, the system can be used to log data and generate reports, allowing the factory manager to identify trends and optimize production processes.

This example demonstrates how Arduino can be used to create a simple and affordable solution to a common manufacturing challenge, improving product quality and efficiency.

The Future of Arduino in Indian Manufacturing

The adoption of Arduino in Indian manufacturing is poised for significant growth, driven by the increasing demand for automation, cost-effectiveness, and rapid prototyping capabilities. The future holds exciting possibilities for Arduino to play a pivotal role in shaping a more advanced and sustainable manufacturing landscape in India.

Emerging Trends and Technologies

The future of Arduino in India is intertwined with emerging trends and technologies that are transforming the manufacturing sector.

- Internet of Things (IoT): The integration of Arduino with IoT technologies will enable the creation of intelligent and connected manufacturing systems. Arduino’s ease of use and versatility make it an ideal platform for developing IoT-enabled devices that can monitor and control production processes, optimize resource utilization, and enhance real-time data analysis.

- Artificial Intelligence (AI): The integration of AI with Arduino will enable the development of intelligent manufacturing systems capable of learning from data, making predictions, and adapting to changing conditions. AI-powered Arduino-based solutions can enhance quality control, optimize production schedules, and improve decision-making in manufacturing environments.

- Cloud Computing: The use of cloud computing with Arduino will enable manufacturers to access powerful computing resources and data storage capabilities. This will facilitate the development of cloud-based manufacturing platforms that can collect, analyze, and share data from Arduino-based devices, enabling better insights and decision-making.

- Robotics and Automation: Arduino’s role in robotics and automation is set to expand significantly. Arduino’s affordability and ease of use make it an ideal platform for developing custom robots and automation solutions for various manufacturing tasks, from material handling to assembly and inspection.

Arduino’s Contribution to a Sustainable Manufacturing Sector

Arduino can play a crucial role in developing a more sustainable manufacturing sector in India.

- Energy Efficiency: Arduino-based solutions can be used to monitor and optimize energy consumption in manufacturing facilities. By integrating Arduino with sensors and actuators, manufacturers can identify areas of energy waste and implement measures to reduce their carbon footprint.

- Waste Reduction: Arduino can be used to develop systems for monitoring and managing waste generation in manufacturing processes. By tracking waste levels and identifying patterns, manufacturers can implement strategies to reduce waste and improve resource utilization.

- Sustainable Manufacturing Practices: Arduino can be used to develop solutions that promote sustainable manufacturing practices, such as implementing closed-loop systems for material recycling and using renewable energy sources in manufacturing operations.

The future of manufacturing in India is bright, and Arduino is playing a pivotal role. As the ecosystem continues to grow and evolve, we can expect to see even more groundbreaking applications emerge, pushing the boundaries of what’s possible in the world of Indian manufacturing. It’s not just about making things; it’s about making them smarter, faster, and more efficient, and Arduino is leading the charge.

Arduino India’s manufacturing scene is booming, with local companies making waves in the world of electronics. But as the AI arms race heats up, some are concerned about the potential for unintended consequences. That’s where Symbolica’s approach comes in, focusing on symbolic models that prioritize transparency and explainability. This could be a valuable lesson for Arduino India, as they continue to develop innovative solutions for the future.

Standi Techno News

Standi Techno News