Fluent Metal takes a stab at the metal 3D printing market, a space already crowded with established players. This newcomer aims to shake things up with a unique approach to metal 3D printing, promising faster production times, higher accuracy, and a wider range of materials. The company’s mission is clear: to revolutionize the way we design and manufacture metal parts, paving the way for a future where intricate designs and complex geometries are no longer a challenge.

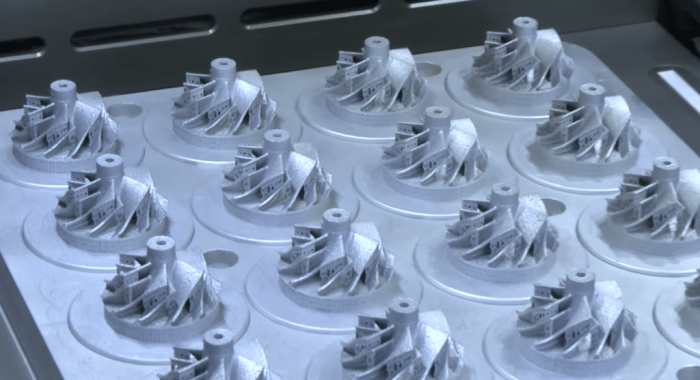

Fluent Metal’s technology is based on a novel process that utilizes a combination of laser melting and selective deposition, enabling them to print complex parts with intricate details. This approach, coupled with their proprietary software, allows for greater control over the printing process, resulting in improved part quality and reduced production costs. The company’s target market spans a wide range of industries, including aerospace, automotive, medical, and consumer goods. With its unique capabilities, Fluent Metal is poised to disrupt the metal 3D printing market and drive innovation across various sectors.

Fluent Metal

Fluent Metal is a relatively new player in the metal 3D printing industry, emerging as a force to be reckoned with. The company’s mission is to revolutionize metal additive manufacturing by offering a technology that’s faster, more efficient, and more affordable than traditional methods.

Fluent Metal’s approach to metal 3D printing stands out because of its focus on speed and affordability. Instead of relying on traditional powder-based processes, Fluent Metal utilizes a unique technology called “Direct Metal Deposition” (DMD). This process involves directly depositing molten metal onto a build platform, eliminating the need for powder handling and reducing overall printing time.

The Company’s Background and Mission

Fluent Metal was founded in 2017 by a team of engineers and scientists with extensive experience in the metal additive manufacturing industry. Their goal was to create a more efficient and cost-effective way to produce metal parts, and they saw a significant opportunity to improve upon existing powder-based processes. Fluent Metal’s mission is to make metal 3D printing accessible to a wider range of businesses and industries, enabling them to take advantage of the technology’s benefits.

Fluent Metal’s Unique Approach to Metal 3D Printing

Fluent Metal’s core technology, Direct Metal Deposition (DMD), distinguishes itself from traditional powder-based metal 3D printing methods. Here’s a breakdown of the key differences:

- Direct Material Deposition: DMD involves depositing molten metal directly onto the build platform, eliminating the need for powder handling and reducing the complexity of the process. This eliminates the need for powder preparation, handling, and post-processing steps, leading to a more streamlined and efficient workflow.

- Faster Build Speeds: The direct deposition approach allows for significantly faster build speeds compared to powder-based methods. This is because the DMD process doesn’t require the same layer-by-layer deposition of powder, allowing for more efficient material deposition and faster part production.

- Enhanced Material Control: DMD provides greater control over the material deposition process, enabling the production of parts with complex geometries and intricate designs. This allows for the creation of parts with greater precision and detail, opening up new possibilities for product design and functionality.

- Reduced Material Waste: DMD minimizes material waste compared to powder-based methods. Since the process involves directly depositing the metal, there’s less material loss during the build process. This results in a more sustainable and cost-effective manufacturing process.

Target Market and Potential Applications

Fluent Metal’s technology is applicable to a wide range of industries, including:

- Aerospace: The company’s technology can be used to produce lightweight and durable components for aircraft, satellites, and other aerospace applications. This could involve creating complex parts for aircraft engines, structural components for spacecraft, or custom tooling for aerospace manufacturing.

- Automotive: Fluent Metal’s technology can be utilized to produce custom parts for vehicles, such as engine components, suspension systems, and body panels. This could lead to the creation of lighter and more efficient vehicles, as well as the production of personalized parts for vehicle customization.

- Medical Devices: The company’s technology can be used to create highly detailed and intricate medical implants, surgical instruments, and other medical devices. This could enable the development of more personalized and effective medical treatments, as well as the production of more complex and innovative medical devices.

- Tooling and Manufacturing: Fluent Metal’s technology can be used to create custom tooling and fixtures for manufacturing processes, such as molds for injection molding, dies for stamping, and jigs for assembly. This could lead to the production of more efficient and accurate tooling, resulting in higher-quality products and improved manufacturing processes.

The Metal 3D Printing Market Landscape

The metal 3D printing market is experiencing rapid growth, driven by advancements in technology, increasing adoption across various industries, and the growing demand for customized and complex metal parts. This market encompasses a wide range of technologies, applications, and players, making it a dynamic and exciting space to observe.

Key Players and Market Trends

The metal 3D printing market is characterized by a diverse range of players, including established companies, startups, and research institutions. Key players in the market include companies like 3D Systems, EOS, GE Additive, Renishaw, and SLM Solutions, among others. These companies are actively involved in developing and commercializing advanced metal 3D printing technologies, materials, and applications.

The market is witnessing several key trends, including:

- Increased adoption of metal 3D printing across various industries: Industries like aerospace, automotive, medical, and tooling are increasingly adopting metal 3D printing for prototyping, tooling, and production. This adoption is driven by the ability of the technology to create complex geometries, reduce lead times, and enable mass customization.

- Development of new and advanced metal 3D printing technologies: Companies are continuously investing in research and development to improve the accuracy, speed, and scalability of metal 3D printing technologies. This includes the development of new printing processes, materials, and software solutions.

- Focus on cost reduction and process optimization: The metal 3D printing industry is focusing on reducing production costs and improving process efficiency to make the technology more accessible and competitive with traditional manufacturing methods.

Growth Opportunities and Driving Factors, Fluent metal takes a stab at the metal 3d printing market

The metal 3D printing market is expected to experience significant growth in the coming years, driven by several factors:

- Growing demand for customized and complex metal parts: Industries are increasingly seeking customized and complex metal parts for their products, and metal 3D printing offers a solution to meet this demand.

- Increased adoption of additive manufacturing in production: Metal 3D printing is becoming an integral part of the production process, particularly for prototyping, tooling, and small-batch production.

- Advancements in materials and processes: Ongoing research and development in metal 3D printing materials and processes are expanding the range of applications and improving the quality and performance of printed parts.

- Government support and initiatives: Governments around the world are investing in research and development of metal 3D printing technologies to promote innovation and drive industrial growth.

Competitive Landscape and Fluent Metal’s Competitors

The metal 3D printing market is highly competitive, with numerous players vying for market share. Fluent Metal faces competition from established players like 3D Systems, EOS, GE Additive, and Renishaw, as well as emerging startups and smaller companies.

Fluent Metal’s key competitors are companies that offer similar metal 3D printing technologies, materials, and applications.

These competitors may offer different strengths and weaknesses, such as:

- Technology focus: Some competitors specialize in specific metal 3D printing technologies, such as powder bed fusion or directed energy deposition.

- Material offerings: Competitors may offer a wide range of metal materials, including stainless steel, titanium, aluminum, and nickel alloys.

- Application expertise: Some competitors have expertise in specific applications, such as aerospace, medical, or tooling.

- Market reach: Competitors may have different geographical market reach and customer bases.

Fluent Metal’s Competitive Advantages

Fluent Metal stands out in the competitive landscape of metal 3D printing with its unique technology that offers significant advantages over traditional methods and existing solutions. Its approach addresses critical limitations of current technologies, paving the way for a new era of metal 3D printing.

Fluent Metal’s Technological Differentiation

Fluent Metal’s technology differentiates itself from its competitors through its innovative approach to metal 3D printing. Unlike other methods that rely on powder-based processes, Fluent Metal utilizes a liquid metal feedstock, enabling greater control over the printing process. This approach offers several key advantages:

- Higher Resolution and Accuracy: Fluent Metal’s liquid metal feedstock allows for finer control over the printing process, resulting in higher resolution and dimensional accuracy compared to powder-based methods. This precision is crucial for producing intricate designs and complex geometries.

- Improved Surface Finish: The liquid metal feedstock eliminates the need for post-processing steps like sanding or polishing, which are often required with powder-based methods. This leads to a smoother surface finish, enhancing the aesthetic appeal and functionality of the printed parts.

- Enhanced Material Properties: Fluent Metal’s technology allows for greater control over the microstructure and properties of the printed metal. This opens up possibilities for creating parts with tailored mechanical properties, such as higher strength, improved ductility, and enhanced wear resistance.

The Impact of Fluent Metal’s Technology on the Metal 3D Printing Market

Fluent Metal’s technology has the potential to revolutionize the metal 3D printing market by addressing existing challenges and opening up new possibilities. The company’s unique approach offers several key benefits:

- Increased Production Efficiency: Fluent Metal’s technology enables faster printing speeds and reduced post-processing time, leading to increased production efficiency. This is particularly beneficial for industries with high-volume production requirements.

- Expansion of Applications: The improved resolution, surface finish, and material properties offered by Fluent Metal’s technology enable the production of parts for a wider range of applications. This includes industries like aerospace, automotive, medical devices, and consumer goods, where high precision and demanding performance requirements are essential.

- Reduced Costs: Fluent Metal’s technology can potentially reduce the cost of metal 3D printing by eliminating the need for expensive post-processing steps and enabling the use of less expensive materials. This makes metal 3D printing more accessible to a wider range of businesses.

Addressing Existing Challenges in the Metal 3D Printing Industry

Fluent Metal’s technology directly addresses several key challenges faced by the metal 3D printing industry:

- Limited Resolution and Accuracy: Powder-based methods often struggle to achieve the high resolution and accuracy required for complex designs. Fluent Metal’s technology overcomes this limitation by utilizing a liquid metal feedstock that enables greater control over the printing process.

- Poor Surface Finish: Powder-based methods often produce parts with rough surface finishes that require extensive post-processing. Fluent Metal’s technology eliminates this issue by producing parts with a smooth surface finish directly from the printing process.

- Limited Material Options: Powder-based methods have limited material options, restricting the range of applications for metal 3D printing. Fluent Metal’s technology opens up possibilities for using a wider range of materials, including those with unique properties.

Applications and Use Cases

Fluent Metal’s technology opens up a world of possibilities across various industries, revolutionizing the way products are designed, manufactured, and used. By combining the benefits of metal 3D printing with advanced materials and processes, Fluent Metal empowers businesses to create innovative solutions that were previously impossible.

Aerospace

The aerospace industry is a prime example of how Fluent Metal’s technology can transform manufacturing. With its ability to create complex, lightweight, and high-performance components, Fluent Metal can help aerospace manufacturers:

- Reduce weight: By creating lighter parts, Fluent Metal helps reduce fuel consumption and increase payload capacity. For example, a recent study by Airbus found that using 3D printed parts could reduce the weight of an aircraft by up to 10%.

- Improve performance: Fluent Metal’s technology enables the creation of parts with intricate geometries and optimized designs, leading to improved aerodynamic performance and fuel efficiency.

- Reduce lead times: By eliminating the need for traditional tooling and manufacturing processes, Fluent Metal can significantly reduce lead times for part production.

Medical

In the medical field, Fluent Metal’s technology is transforming the way medical devices are designed and manufactured. The ability to create highly customized and biocompatible implants, instruments, and tools is revolutionizing healthcare:

- Personalized implants: Fluent Metal enables the creation of implants that are tailored to the specific needs of each patient, leading to better outcomes and faster recovery times. For example, 3D printed titanium implants are now being used to replace damaged bone in patients with hip and knee replacements.

- Minimally invasive surgery: Fluent Metal’s technology enables the creation of intricate surgical instruments and tools that can be used in minimally invasive procedures, reducing the risk of complications and improving patient recovery.

- Biocompatible materials: Fluent Metal’s technology allows for the use of biocompatible materials in medical devices, reducing the risk of rejection and improving patient safety.

Automotive

The automotive industry is embracing Fluent Metal’s technology to create lighter, stronger, and more efficient vehicles:

- Lightweight components: Fluent Metal’s technology allows for the creation of lightweight components, such as engine parts and chassis components, reducing fuel consumption and improving vehicle performance.

- Improved safety: Fluent Metal’s technology can be used to create safety-critical components, such as airbags and seatbelts, with improved strength and durability.

- Customizable designs: Fluent Metal’s technology enables the creation of highly customized parts, allowing for the development of unique and innovative vehicle designs.

Future Prospects and Challenges: Fluent Metal Takes A Stab At The Metal 3d Printing Market

Fluent Metal’s innovative metal 3D printing technology has the potential to revolutionize the manufacturing landscape. Its ability to create complex metal parts with intricate geometries and high precision opens up a world of possibilities for various industries. However, the journey ahead will be filled with both exciting opportunities and significant challenges.

Growth and Expansion

Fluent Metal’s future success hinges on its ability to scale its operations and expand its reach into new markets. The company will need to invest in research and development to further enhance its technology, improve its manufacturing capabilities, and reduce production costs. Additionally, Fluent Metal should consider expanding its geographical presence by establishing partnerships or setting up manufacturing facilities in strategic locations.

Market Adoption and Competition

As the metal 3D printing market continues to grow, Fluent Metal will face increasing competition from established players and emerging startups. To stay ahead of the curve, the company must focus on developing a clear value proposition, highlighting the unique advantages of its technology, and building strong customer relationships.

Technological Advancements

The field of metal 3D printing is constantly evolving, with new technologies and materials emerging regularly. Fluent Metal must remain at the forefront of these advancements by investing in research and development, collaborating with leading institutions, and actively monitoring industry trends.

Regulation and Safety

As metal 3D printing becomes more widely adopted, concerns regarding safety and environmental impact will arise. Fluent Metal must proactively address these concerns by developing safe operating procedures, ensuring responsible disposal of materials, and working with regulatory bodies to establish industry standards.

Economic and Societal Impact

Fluent Metal’s technology has the potential to significantly impact the manufacturing landscape, leading to job creation, increased productivity, and reduced manufacturing lead times. However, the company must be mindful of the potential societal impact of its technology, such as displacement of workers in traditional manufacturing industries.

As Fluent Metal enters the metal 3D printing market, it faces both opportunities and challenges. The company’s unique technology and focus on innovation have the potential to disrupt the industry and drive significant growth. However, Fluent Metal will need to overcome challenges such as competition from established players and the need to scale its operations to meet growing demand. The success of Fluent Metal will depend on its ability to continue innovating, build strong partnerships, and effectively communicate the value of its technology to potential customers. The future of metal 3D printing is bright, and Fluent Metal is well-positioned to play a significant role in shaping its evolution.

Fluent Metal is diving headfirst into the metal 3D printing market, hoping to shake things up with their innovative approach. This move comes at a time when AI is rapidly transforming various industries, like music production, as seen with createsafe the company behind Grimes’ voice cloning tool launching new AI tools. Fluent Metal’s ambition is to bring similar disruption to the metal fabrication world, offering faster, more precise, and more cost-effective solutions.

Standi Techno News

Standi Techno News