Rocket lab leverages vertical integration to land 515m military satellite contract – Rocket Lab Lands 515M Military Contract with Vertical Integration: In a move that’s shaking up the space industry, Rocket Lab has landed a massive $515 million contract with the US military. This isn’t just a big win for the company; it’s a testament to their unique vertical integration strategy. Unlike many space companies that rely on external suppliers for various components, Rocket Lab controls almost every step of the process, from designing and manufacturing rockets to building and launching satellites. This strategy has not only allowed them to streamline operations but also secure this significant military contract, positioning them as a major player in the rapidly growing small satellite launch market.

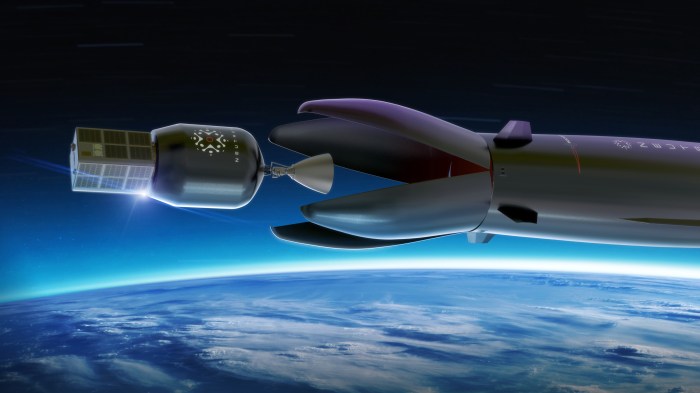

The contract involves launching a custom-built satellite designed for the US military, highlighting Rocket Lab’s ability to cater to specific needs. This isn’t just about launching satellites; it’s about providing comprehensive solutions, which is where Rocket Lab’s vertical integration really shines. By controlling every aspect of the process, they can offer greater flexibility, faster turnaround times, and ultimately, a more cost-effective solution for their clients. This has clearly resonated with the US military, who are increasingly turning to small satellite launches for various missions.

Rocket Lab’s Vertical Integration Strategy

Rocket Lab’s vertical integration strategy has been a key factor in its success, particularly in securing the recent $515 million military satellite contract. By controlling a significant portion of its supply chain, Rocket Lab has gained a competitive edge in the space industry, allowing it to offer innovative solutions and maintain greater control over its operations.

Vertical Integration Strategy Elements

Vertical integration is a business strategy where a company expands its operations to control multiple stages of its production process, from raw materials to final product. Rocket Lab has adopted this strategy in a number of ways:

- Rocket Manufacturing: Rocket Lab designs and manufactures its own Electron launch vehicle, giving it complete control over its performance, reliability, and cost. This eliminates the need to rely on external suppliers for critical components, reducing potential delays and ensuring consistency in quality.

- Engine Production: The company manufactures its own Rutherford engines, which power the Electron rocket. This allows for greater control over engine performance and design, enabling Rocket Lab to optimize its rockets for specific mission requirements.

- Ground Infrastructure: Rocket Lab owns and operates its own launch sites, including the Launch Complex 1 in New Zealand and Launch Complex 2 in Virginia, USA. This provides it with complete control over launch operations and reduces reliance on third-party facilities.

- Satellite Manufacturing: Rocket Lab has expanded into satellite manufacturing with its Photon platform. This allows the company to offer complete end-to-end solutions, including satellite design, construction, launch, and in-space operations.

Comparison with Other Companies

Rocket Lab’s approach to vertical integration stands out in the space industry. While other companies, such as SpaceX, also practice vertical integration, Rocket Lab’s strategy is particularly focused on its smaller-scale, agile approach.

- SpaceX: SpaceX’s vertical integration strategy is more extensive, encompassing rocket manufacturing, engine production, satellite manufacturing, and even its own launchpad construction. This allows for greater control over the entire space mission lifecycle.

- Blue Origin: Blue Origin, another prominent player in the space industry, focuses on vertical integration in specific areas, such as engine development and reusable launch vehicle technology.

- Traditional Space Companies: Traditional space companies often rely on a more fragmented supply chain, outsourcing critical components and services to specialized contractors. This can lead to increased costs, delays, and reduced control over quality.

Advantages of Vertical Integration

Vertical integration offers several advantages for Rocket Lab, contributing to its ability to secure the $515 million military satellite contract:

- Cost Efficiency: By controlling its own production process, Rocket Lab can potentially reduce costs by eliminating middlemen and negotiating favorable prices for raw materials.

- Innovation: Vertical integration allows Rocket Lab to innovate more quickly and effectively, as it can directly integrate new technologies and designs into its products without relying on external suppliers.

- Supply Chain Control: Vertical integration provides Rocket Lab with greater control over its supply chain, reducing the risk of delays and ensuring consistent quality. This is particularly important in the highly competitive space industry.

- Competitive Advantage: Vertical integration gives Rocket Lab a competitive edge by allowing it to offer more competitive pricing, faster turnaround times, and tailored solutions to meet specific customer needs.

Disadvantages of Vertical Integration

While vertical integration offers numerous benefits, it also presents certain challenges:

- Higher Initial Investment: Building and maintaining an integrated supply chain requires significant upfront investment, which can be a barrier for smaller companies.

- Increased Complexity: Managing a complex, vertically integrated supply chain can be challenging and require specialized expertise in various fields.

- Potential for Bottlenecks: If one stage of the production process experiences delays or disruptions, it can affect the entire supply chain, potentially impacting delivery timelines.

- Limited Flexibility: Vertical integration can limit flexibility in responding to changing market demands or technological advancements, as it can be difficult to adapt quickly to new requirements.

The Significance of the 515 Million Dollar Military Satellite Contract

Rocket Lab’s recent 515 million dollar contract to launch a military satellite for the US government marks a significant milestone for the company, solidifying its position as a major player in the growing small satellite launch market. The contract underscores the capabilities of Rocket Lab’s launch vehicles and the increasing demand for small satellites within the military sector.

Capabilities of the Satellite

The satellite, designated as a “classified payload,” is expected to provide advanced capabilities for the US military, contributing to critical national security objectives. While specific details regarding the satellite’s capabilities remain confidential, it is likely to encompass advanced technologies such as:

- High-resolution imaging: This allows for detailed observation of ground targets, enabling the military to monitor potential threats, assess damage, and gather intelligence.

- Communication relay: The satellite can serve as a communication hub, facilitating secure and reliable data transfer between military assets and command centers, enhancing operational efficiency and responsiveness.

- Signal intelligence: The satellite can intercept and analyze electronic signals, providing valuable insights into enemy activities and communication patterns.

Positioning Rocket Lab in the Small Satellite Launch Market

The contract reinforces Rocket Lab’s position as a leading provider of small satellite launch services, particularly within the rapidly growing military sector. The US Department of Defense is increasingly relying on smaller, more agile satellites for various missions, and Rocket Lab’s launch vehicles are well-suited to meet these requirements. This contract showcases Rocket Lab’s ability to handle complex military missions, demonstrating its technical expertise and reliability.

Implications for Rocket Lab’s Future Growth

The contract signifies a significant step forward for Rocket Lab’s growth trajectory. It not only provides a substantial financial boost but also serves as a powerful testament to the company’s capabilities. This success is likely to attract further government and commercial contracts, bolstering Rocket Lab’s position as a key player in the space industry.

For example, the US Air Force’s Space Systems Command has already awarded Rocket Lab contracts for launching smaller, experimental satellites, demonstrating the agency’s confidence in the company’s technology. Similarly, commercial companies are increasingly turning to Rocket Lab for launching their own constellations of small satellites, which are used for various purposes, including internet connectivity, Earth observation, and scientific research.

The Impact of Vertical Integration on Rocket Lab’s Operations: Rocket Lab Leverages Vertical Integration To Land 515m Military Satellite Contract

Vertical integration has been a cornerstone of Rocket Lab’s success, enabling the company to achieve faster development cycles, reduce costs, and maintain a competitive edge in the rapidly evolving space industry. By controlling key aspects of its operations, from engine design and manufacturing to satellite construction and launch services, Rocket Lab has streamlined its processes and fostered a culture of innovation.

Faster Development Cycles and Production Timelines

Vertical integration has significantly reduced Rocket Lab’s development cycles and production timelines. By managing all stages of the process in-house, the company can eliminate the delays and communication challenges associated with relying on external suppliers. This allows Rocket Lab to respond quickly to market demands and customer needs, ensuring a competitive advantage in the space launch industry.

- Reduced Lead Times: By manufacturing its own engines and components, Rocket Lab can significantly reduce lead times for production. This agility allows the company to launch rockets more frequently and meet customer deadlines efficiently.

- Streamlined Communication: Direct control over the entire development and production process eliminates the need for complex communication channels and reduces the risk of miscommunication. This streamlined approach enhances collaboration and efficiency.

- Improved Flexibility: Vertical integration allows Rocket Lab to adapt quickly to changes in customer requirements or market trends. This flexibility is crucial in the dynamic space industry, where technology and regulations are constantly evolving.

In-House Innovation and Technological Advancements

Rocket Lab’s vertical integration has allowed it to foster a culture of innovation and develop new technologies in-house. By controlling its research and development processes, the company can explore new ideas and push the boundaries of space technology.

- Engine Design and Optimization: Rocket Lab has developed its own proprietary engine, the Rutherford, which is characterized by its high performance and cost-effectiveness. The company’s in-house engine design and manufacturing capabilities allow it to continuously improve the engine’s performance and efficiency.

- 3D Printing for Spacecraft Components: Rocket Lab has adopted 3D printing for the production of spacecraft components, which has significantly reduced production time and costs. This innovative approach has enabled the company to develop lightweight and durable components, enhancing its spacecraft’s performance.

- Software and Control Systems: Rocket Lab has developed its own software and control systems for its rockets and ground stations. This in-house expertise allows the company to optimize its launch operations and ensure reliable performance.

Challenges of Maintaining Vertical Integration

While vertical integration offers significant advantages, Rocket Lab faces challenges in maintaining this strategy as it scales its operations. As the company expands its launch capacity and customer base, it needs to ensure that its in-house capabilities can keep pace with the increased demand.

- Resource Allocation and Management: Maintaining a vertically integrated structure requires significant resources and efficient management. As Rocket Lab scales its operations, it needs to ensure that it has the necessary workforce, infrastructure, and financial resources to support its ambitious growth plans.

- Balancing Innovation and Efficiency: While vertical integration fosters innovation, it can also create challenges in maintaining operational efficiency. Rocket Lab needs to strike a balance between investing in research and development and ensuring cost-effective production processes.

- Flexibility and Adaptability: Vertical integration can sometimes limit flexibility, as the company relies heavily on its in-house capabilities. Rocket Lab needs to be adaptable to changing market conditions and technological advancements, ensuring that its vertically integrated structure does not become a bottleneck to growth.

The Future of Rocket Lab and Vertical Integration in the Space Industry

Rocket Lab’s vertical integration strategy has positioned it as a leader in the rapidly growing space industry. This strategy, coupled with its innovative technologies and agile approach, has enabled the company to achieve significant milestones and capture a considerable market share. Looking ahead, Rocket Lab’s vertical integration is expected to play an even more crucial role in its future success, driving innovation and competitiveness in the evolving space landscape.

Advantages and Disadvantages of Vertical Integration in the Space Industry, Rocket lab leverages vertical integration to land 515m military satellite contract

Vertical integration in the space industry offers both advantages and disadvantages, impacting cost, innovation, and market share.

| Factor | Advantages | Disadvantages |

|---|---|---|

| Cost | – Reduced procurement costs by controlling the supply chain. – Potential for economies of scale through internal production. – Improved efficiency and streamlined operations. |

– High initial investment required to establish in-house capabilities. – Risk of cost overruns if internal production is inefficient. – Potential for increased bureaucracy and inflexibility. |

| Innovation | – Enhanced control over product development and design. – Faster turnaround times for new products and services. – Greater flexibility to adapt to changing market demands. |

– Potential for stagnation if internal innovation is not prioritized. – Reduced access to external expertise and technologies. – Increased risk of falling behind competitors with faster innovation cycles. |

| Market Share | – Improved control over pricing and distribution channels. – Enhanced competitiveness through unique product offerings. – Greater ability to respond to customer needs. |

– Increased risk of losing market share if products are not competitive. – Potential for reduced flexibility in adapting to market shifts. – Limited ability to leverage external partnerships for growth. |

Timeline of Key Events Shaping Rocket Lab’s Journey

Rocket Lab’s journey has been marked by several key events that have shaped its success, highlighting the role of vertical integration in its growth.

- 2006: Rocket Lab was founded by Peter Beck, with a vision to provide affordable access to space.

- 2013: The company’s first successful launch of the Electron rocket, demonstrating its commitment to developing innovative and reliable launch vehicles.

- 2017: Rocket Lab established its own rocket engine manufacturing facility, further integrating its operations and reducing reliance on external suppliers.

- 2019: The company successfully landed the first Electron rocket, demonstrating its expertise in reusable launch technologies.

- 2021: Rocket Lab expanded its vertical integration by acquiring the satellite manufacturer, “Another company”, further strengthening its position in the end-to-end space services market.

Hypothetical Scenario of Rocket Lab’s Vertical Integration Strategy

In the coming years, Rocket Lab’s vertical integration strategy is likely to evolve, driven by technological advancements and competitive pressures.

“Rocket Lab’s vertical integration strategy will likely focus on expanding its in-house capabilities in areas such as advanced propulsion systems, satellite manufacturing, and ground station networks. The company could also explore partnerships with other space companies to further enhance its vertical integration and access new technologies.”

This strategy could lead to a scenario where Rocket Lab becomes a fully integrated space company, offering a comprehensive suite of services from launch to satellite operation. By controlling key aspects of the space value chain, Rocket Lab could potentially reduce costs, improve efficiency, and gain a competitive advantage in the rapidly evolving space market.

Rocket Lab’s success with this contract is a clear indication that their vertical integration strategy is paying off. Not only has it enabled them to secure this lucrative deal, but it has also positioned them for future growth in both the commercial and government sectors. As the demand for small satellite launches continues to rise, Rocket Lab is poised to become a dominant force in the industry. Their ability to innovate and deliver customized solutions, all while maintaining cost efficiency, is a winning combination that will likely attract more clients and contracts in the years to come.

Rocket Lab’s vertical integration strategy is paying off, securing a massive $515 million contract for a military satellite. This win comes at a time when the space industry is seeing some turbulence, with companies like Bird facing bankruptcy, bird bankruptcy which underscores the importance of strong financial footing and a clear vision. Rocket Lab’s focus on in-house development and manufacturing allows them to control costs and deliver reliable solutions, a key factor in winning over the US military.

Standi Techno News

Standi Techno News