3D Printing: A Leap Forward with Accelerated Speeds

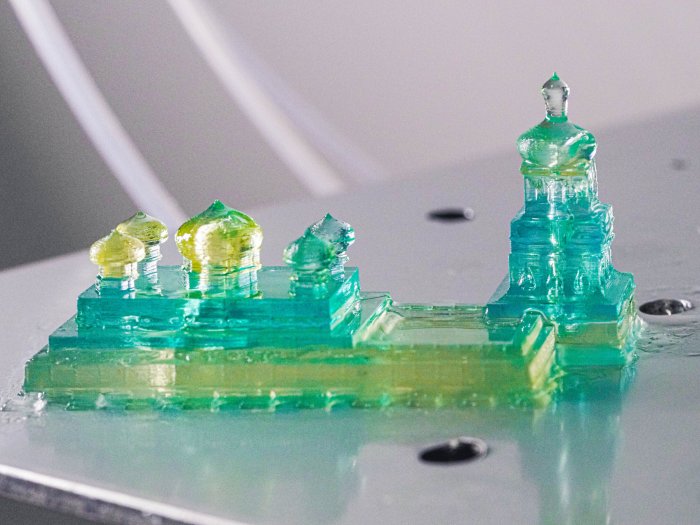

3D printing, also known as additive manufacturing, has revolutionized the way we create objects. It involves building three-dimensional objects layer by layer from a digital design using materials like plastics, metals, ceramics, and composites. However, the speed at which 3D printers can produce objects has been a significant limitation, hindering its widespread adoption in various industries.

The need for faster 3D printing is crucial for a multitude of reasons. Imagine designing a custom prosthetic limb in minutes, printing intricate parts for a spacecraft in hours, or creating personalized medical devices in real-time. These are just a few examples of how accelerated printing speeds could transform industries like healthcare, manufacturing, and aerospace.

Introducing the New 3D Printing Method

A new 3D printing method has emerged, promising to dramatically increase printing speeds by 25 to 100 times. This groundbreaking technology has the potential to revolutionize the field, opening up new possibilities and expanding the applications of 3D printing.

The New 3D Printing Method: New 3d Printing Method Promises To Print 25 100 Times Faster

The revolutionary 3D printing method promises to print objects 25 to 100 times faster than existing techniques. This breakthrough has the potential to disrupt various industries, from manufacturing and healthcare to aerospace and consumer goods.

This new method leverages a novel approach to material deposition, enabling rapid layer-by-layer construction of complex 3D objects.

Comparison with Existing 3D Printing Techniques

The new method stands apart from conventional 3D printing techniques like Fused Deposition Modeling (FDM) and Stereolithography (SLA) in several key aspects.

- Material Deposition: Existing methods like FDM extrude molten plastic filaments, while SLA uses UV light to solidify liquid resin. The new method employs a different material deposition mechanism, allowing for faster and more efficient material application.

- Layer Formation: Traditional techniques build objects layer by layer, with each layer taking a certain amount of time to solidify or cool. The new method reduces the time required for layer formation, significantly accelerating the overall printing process.

- Printing Resolution: While existing methods have limitations in resolution and detail, the new method is designed to achieve high resolution and intricate details, allowing for the creation of complex geometries and designs.

Key Innovations Enabling Faster Printing Speeds

The new method incorporates several key innovations that enable its remarkable speed advantage:

- High-Speed Material Deposition: The method employs a novel material deposition system that allows for rapid and precise material application. This high-speed deposition significantly reduces the time required to build each layer of the object.

- Parallel Processing: Unlike conventional methods that work on a single layer at a time, the new method utilizes parallel processing techniques. This allows for multiple layers to be built simultaneously, further accelerating the printing process.

- Optimized Layer Formation: The method incorporates optimized layer formation techniques that minimize the time required for each layer to solidify or cool. This allows for faster transition to the next layer, resulting in a significant speed improvement.

Speed and Efficiency

The new 3D printing method promises a significant leap forward in terms of speed and efficiency, boasting a 25 to 100 times faster printing rate compared to conventional methods. This remarkable acceleration stems from several key innovations, revolutionizing the way we approach 3D printing.

Factors Contributing to Increased Speed

The dramatic increase in printing speed is attributed to a combination of innovative factors:

- High-Speed Extrusion: The new method utilizes a high-speed extrusion system that allows for rapid deposition of material, drastically reducing printing time. This system employs advanced nozzles and precise control mechanisms to ensure accurate and consistent material flow at high speeds.

- Optimized Print Paths: The printing software has been enhanced to optimize print paths, minimizing unnecessary movements and maximizing efficiency. This optimization ensures that the printing head travels the shortest distance possible, resulting in faster printing times.

- Parallel Printing: Some implementations of the new method leverage parallel printing techniques, where multiple print heads operate simultaneously. This allows for the simultaneous deposition of material in different areas of the print, significantly reducing overall printing time.

Impact on Production Costs and Turnaround Times

The accelerated printing speeds offered by this new method have profound implications for production costs and turnaround times.

- Reduced Production Costs: Faster printing translates to reduced production time, leading to lower labor costs and energy consumption. This efficiency directly translates to lower production costs, making 3D printing more accessible and cost-effective for a wider range of applications.

- Shorter Turnaround Times: The ability to print objects significantly faster enables quicker prototyping and production cycles. This agility allows businesses to respond to market demands and changing trends more effectively, giving them a competitive edge.

Applications and Industries

The accelerated printing speeds enabled by this new 3D printing method have the potential to revolutionize various industries, offering faster prototyping, increased production efficiency, and the creation of more complex designs.

The impact of this technology will be felt across numerous sectors, with potential for widespread adoption and significant economic benefits.

Manufacturing

The automotive, aerospace, and consumer goods industries stand to gain significantly from faster 3D printing.

- Prototyping: Rapid prototyping enables quicker product iterations and design testing, reducing development time and accelerating product launches.

- Production: Large-scale production of complex components, such as customized car parts or intricate aircraft components, can be achieved more efficiently.

- Customization: Mass customization becomes more feasible, allowing for the creation of personalized products tailored to individual customer needs.

Healthcare, New 3d printing method promises to print 25 100 times faster

Faster 3D printing opens new possibilities in the healthcare industry, particularly in the fields of prosthetics, implants, and personalized medicine.

- Prosthetics: Complex and customized prosthetic limbs can be printed faster, enabling quicker rehabilitation and improving patient outcomes.

- Implants: Printing intricate implants with precise geometries and biocompatible materials becomes more efficient, leading to improved surgical procedures and patient recovery.

- Personalized Medicine: Customized medical devices and surgical guides can be printed on demand, tailored to individual patient needs and anatomy.

Architecture and Construction

The construction industry can leverage faster 3D printing for creating complex architectural structures, building prototypes, and producing customized components.

- Building Prototypes: Architectural models can be printed quickly and cost-effectively, allowing for faster design iterations and client presentations.

- Custom Components: Customized architectural elements, such as intricate facade panels or complex window frames, can be printed with precision and speed.

- Construction: 3D printing can be used to create entire buildings or structural components, reducing construction time and labor costs.

Education and Research

Faster 3D printing empowers educational institutions and research labs with tools for creating complex models, prototypes, and experimental setups.

- STEM Education: Students can engage in hands-on learning experiences by creating intricate models and prototypes, fostering creativity and problem-solving skills.

- Research: Scientists and engineers can utilize faster 3D printing for creating complex prototypes and experimental setups, accelerating research and development.

- Design and Innovation: Faster printing speeds encourage experimentation and innovation, allowing for the creation of complex designs and intricate prototypes.

Art and Design

The new printing method opens doors for artists and designers to create intricate sculptures, complex jewelry, and personalized art pieces.

- Sculptures: Complex and detailed sculptures can be printed with speed and precision, pushing the boundaries of artistic expression.

- Jewelry: Personalized jewelry designs can be printed quickly and cost-effectively, allowing for unique and bespoke creations.

- Art Installations: Large-scale and intricate art installations can be printed in a fraction of the time, enabling ambitious artistic projects.

Future Implications

The advent of this groundbreaking 3D printing method, capable of achieving speeds 25 to 100 times faster than conventional methods, heralds a new era in additive manufacturing. This technological leap forward holds immense potential to revolutionize various industries and reshape the future of 3D printing.

Impact on the Future of 3D Printing

The accelerated printing speeds offered by this new method will significantly impact the future of 3D printing. Faster production times will enable manufacturers to:

- Reduce production costs: By significantly reducing the time required to print objects, manufacturers can lower labor costs and achieve greater efficiency in their production processes. This cost reduction will make 3D printing more accessible to a wider range of businesses and individuals, potentially driving mass adoption.

- Increase production volume: The ability to print objects much faster will enable manufacturers to increase production volumes, meeting the demands of larger markets and shorter lead times. This will be particularly advantageous for industries like consumer goods, where quick turnaround times are essential.

- Enable rapid prototyping: The speed of this new method will revolutionize the prototyping process, allowing designers and engineers to create and test multiple iterations of a product in a fraction of the time. This will accelerate the product development cycle and enable faster innovation.

- Promote customization and personalization: The accessibility and speed of this new technology will allow for greater customization and personalization of products. Consumers can design and print their own objects, leading to a more diverse and unique product landscape.

Advancements in Printing Speed and Resolution

This new method opens up avenues for further advancements in printing speed and resolution.

- Multi-material printing: The development of faster printing methods will pave the way for multi-material printing, where objects can be printed with different materials simultaneously. This will allow for the creation of complex objects with varying properties, such as strength, flexibility, and conductivity.

- Increased resolution: As printing speeds increase, it will become possible to achieve higher resolutions, leading to finer details and more intricate designs. This will expand the possibilities for 3D printing in fields like jewelry making, medical implants, and microelectronics.

- Continuous printing: Future advancements may lead to continuous printing, where objects are printed without interruption. This will further reduce production time and enable the creation of larger and more complex objects.

Creating New Materials and Functionalities

The rapid advancements in 3D printing technology are not only driving improvements in speed and resolution but also enabling the creation of new materials and functionalities.

- Bioprinting: This new method holds significant promise for bioprinting, the creation of living tissues and organs. Faster printing speeds will allow for the fabrication of more complex and intricate structures, paving the way for personalized medicine and organ transplantation.

- Smart materials: The ability to print with multiple materials and achieve higher resolutions opens up opportunities for creating smart materials that can respond to changes in their environment. This will enable the development of self-healing materials, shape-shifting structures, and responsive surfaces.

- 4D printing: This new method could facilitate the development of 4D printing, where objects can change their shape and form over time in response to external stimuli. This technology has the potential to revolutionize architecture, fashion, and robotics.

Challenges and Limitations

While the prospect of significantly faster 3D printing is exciting, there are inherent challenges and limitations that need to be addressed to ensure the widespread adoption and practical application of this new technology.

The rapid printing speeds, while promising, come with potential trade-offs in terms of print quality, material properties, and process control. Further research and development are crucial to optimize the technology and address these limitations.

Potential Challenges and Limitations

The rapid development of this new 3D printing method presents a number of challenges that require further research and development to overcome.

- Print Quality and Resolution: The high speeds of the new method could potentially compromise print quality and resolution, especially for intricate designs or applications requiring fine details. This is a critical concern for industries like medical devices, where precision and accuracy are paramount.

- Material Compatibility: The new method might not be compatible with all existing 3D printing materials, particularly those with complex chemical compositions or sensitive properties. Expanding the range of compatible materials is crucial for broader adoption.

- Process Control and Repeatability: Maintaining consistent and reliable process control at such high printing speeds is challenging. Ensuring repeatability and minimizing variations in printed objects across different batches is essential for manufacturing applications.

- Cost and Scalability: The initial cost of implementing the new technology might be high, especially for industrial-scale production. Scaling up production and making the technology widely accessible requires cost-effective solutions and manufacturing processes.

Further Research and Development

To overcome these challenges and unlock the full potential of this new 3D printing method, extensive research and development are necessary in the following areas:

- Material Science: Developing new materials specifically designed for high-speed 3D printing, focusing on properties like thermal stability, flow characteristics, and adhesion. This will expand the range of applications and enhance the functionality of printed objects.

- Process Optimization: Fine-tuning the printing parameters, such as laser power, scanning speed, and layer thickness, to achieve optimal print quality and repeatability at high speeds. This involves a thorough understanding of the interplay between process variables and material behavior.

- Software Development: Developing advanced software tools to manage and control the high-speed printing process, ensuring accurate data processing, precise layer deposition, and efficient workflow.

- Equipment Design: Innovating in equipment design to enhance the precision, stability, and durability of the printing system at high speeds. This might involve incorporating advanced sensors, feedback mechanisms, and robust mechanical components.

Scaling Up Production and Accessibility

To make the technology widely accessible and applicable for mass production, several key considerations are crucial:

- Cost Reduction: Developing cost-effective manufacturing processes for the printing equipment and materials will be essential for widespread adoption. This might involve utilizing readily available materials and simplifying the manufacturing process.

- Industry Partnerships: Collaborating with manufacturers, technology companies, and research institutions to accelerate the development, testing, and deployment of the technology. This will leverage expertise and resources to overcome challenges and create practical solutions.

- Standardization and Interoperability: Establishing industry standards for file formats, printing protocols, and material specifications will promote compatibility and interoperability between different manufacturers and software systems. This will streamline the adoption process and facilitate the exchange of data and designs.

New 3d printing method promises to print 25 100 times faster – The new 3D printing method is poised to change the game, opening up a new era of rapid prototyping and production. This technology has the potential to revolutionize how we design, create, and manufacture products. With its speed and efficiency, it could transform industries, lower production costs, and enable the creation of more intricate and complex designs. The future of 3D printing is bright, and this new method is a shining example of the exciting advancements that lie ahead.

Imagine printing a whole house in a matter of hours, not days! That’s the promise of a new 3D printing method that claims to be 25 to 100 times faster than current technology. But before you get too excited about your own custom-printed mansion, remember that even with lightning-fast printing, you might need to familiarize yourself with Apple’s exchange and refund policy in Hong Kong if your 3D printed masterpiece isn’t quite what you expected.

So, while the future of 3D printing is looking bright, it’s always good to be prepared for any unexpected bumps in the road.

Standi Techno News

Standi Techno News