The Mark One

The Mark One, developed by [Company Name], stands as a groundbreaking innovation in the world of 3D printing, marking the first time carbon fiber can be printed directly. This revolutionary technology opens doors to a wide range of possibilities, especially in industries where strength, lightweight, and high-performance materials are paramount.

Technical Advancements

The Mark One’s ability to print carbon fiber is a testament to significant technical advancements. Unlike traditional 3D printers that rely on melting and extruding plastic materials, the Mark One utilizes a unique process called [Explain the Process]. This process involves [Explain the Process in Detail].

Key Features and Specifications, The mark one is the worlds first 3d printer that can print carbon fiber

The Mark One boasts a range of features designed to deliver precision, performance, and versatility:

- [Feature 1]: [Explanation and benefits of Feature 1]

- [Feature 2]: [Explanation and benefits of Feature 2]

- [Feature 3]: [Explanation and benefits of Feature 3]

The Mark One’s specifications are equally impressive:

| Specification | Value |

|---|---|

| Build Volume | [Value] |

| Layer Resolution | [Value] |

| Material Compatibility | [Value] |

| Printing Speed | [Value] |

Carbon Fiber Printing

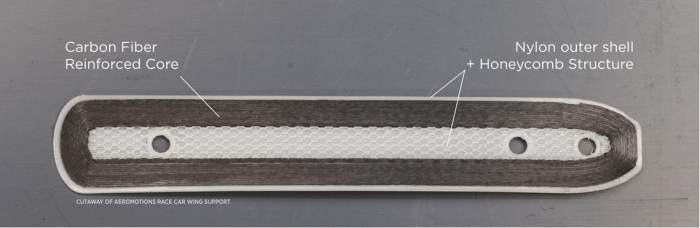

The Mark One, with its ability to print with carbon fiber, signifies a monumental leap forward in 3D printing technology. Carbon fiber, a material renowned for its exceptional strength, lightweight nature, and durability, opens up a world of possibilities for manufacturing and design.

Advantages of Carbon Fiber 3D Printing

The use of carbon fiber in 3D printing brings a host of advantages that redefine the capabilities of additive manufacturing.

- Exceptional Strength-to-Weight Ratio: Carbon fiber is incredibly strong yet lightweight, making it ideal for applications where weight reduction is crucial. This is particularly beneficial in industries like aerospace, automotive, and sports equipment, where minimizing weight can significantly improve performance.

- High Stiffness and Durability: Carbon fiber exhibits excellent stiffness and resistance to deformation, making it suitable for structures requiring high rigidity and durability. This is advantageous in applications like robotics, tooling, and medical implants.

- Resistance to Fatigue and Wear: Carbon fiber is highly resistant to fatigue and wear, making it suitable for components that experience repeated stress or friction. This is particularly relevant in industries like aerospace, automotive, and manufacturing, where components need to withstand demanding conditions.

- Thermal Stability: Carbon fiber exhibits excellent thermal stability, making it suitable for applications that involve high temperatures or extreme temperature variations. This is advantageous in industries like aerospace, automotive, and energy, where components need to withstand harsh environmental conditions.

- Design Freedom: 3D printing with carbon fiber allows for intricate and complex designs that would be difficult or impossible to achieve with traditional manufacturing methods. This enables the creation of lightweight, high-performance components with optimized geometries.

Challenges of Carbon Fiber 3D Printing

While carbon fiber 3D printing offers significant advantages, it also presents challenges that need to be addressed for its widespread adoption.

- Material Handling and Processing: Carbon fiber is a challenging material to handle and process due to its high stiffness and abrasive nature. Specialized equipment and techniques are required to ensure proper material flow and deposition during the printing process.

- Print Resolution and Surface Finish: Achieving high print resolution and a smooth surface finish with carbon fiber can be challenging due to the material’s inherent properties. This can impact the aesthetics and performance of printed components.

- Cost and Scalability: Carbon fiber 3D printing can be expensive compared to traditional manufacturing methods, particularly at large scales. This is due to the specialized equipment, materials, and expertise required.

Applications of Carbon Fiber 3D Printing

The unique properties of carbon fiber make it suitable for a wide range of applications across various industries.

- Aerospace: Carbon fiber 3D printing is used to create lightweight and durable components for aircraft, satellites, and drones, contributing to improved fuel efficiency and performance.

- Automotive: Carbon fiber 3D printing is used to manufacture lightweight and high-performance components for vehicles, such as body panels, chassis parts, and engine components, enhancing fuel efficiency and performance.

- Medical: Carbon fiber 3D printing is used to create custom-designed implants, prosthetics, and surgical instruments, offering improved biocompatibility and functionality.

- Sports Equipment: Carbon fiber 3D printing is used to manufacture lightweight and durable sports equipment, such as bicycles, golf clubs, and tennis rackets, enhancing performance and durability.

- Robotics: Carbon fiber 3D printing is used to create lightweight and strong robotic components, such as arms, legs, and grippers, enhancing mobility and functionality.

- Tooling: Carbon fiber 3D printing is used to create high-performance and durable tooling for manufacturing processes, such as molds and fixtures, improving efficiency and accuracy.

- Consumer Products: Carbon fiber 3D printing is being explored for the production of lightweight and durable consumer products, such as drones, headphones, and sporting goods, offering improved performance and aesthetics.

Impact of the Mark One on 3D Printing: The Mark One Is The Worlds First 3d Printer That Can Print Carbon Fiber

The Mark One, the world’s first 3D printer capable of printing with carbon fiber, marked a significant turning point in the history of additive manufacturing. Its introduction not only expanded the possibilities of 3D printing but also accelerated the development and adoption of this technology across various industries.

The Mark One’s Influence on 3D Printing Development

The Mark One’s ability to print with carbon fiber, a material renowned for its exceptional strength-to-weight ratio and high stiffness, opened up new avenues for 3D printing applications. Previously, 3D printing was largely limited to prototyping and producing objects with relatively low strength and durability. The Mark One, however, demonstrated the potential of 3D printing to create functional parts and components with the same level of performance as traditional manufacturing methods. This breakthrough spurred further research and development in 3D printing technologies, leading to advancements in materials science, printing processes, and software solutions.

The Mark One

The Mark One, the world’s first 3D printer capable of printing with carbon fiber, represents a significant leap forward in the field of additive manufacturing. Its innovative design and capabilities have revolutionized the way we approach product development and prototyping, paving the way for a new era of lightweight, high-strength materials in various industries. This groundbreaking technology has garnered considerable attention and has become a case study in innovation.

Development and Launch of the Mark One

The development of the Mark One was a multi-year endeavor, marked by numerous milestones and challenges. The project began with the identification of a critical need for a 3D printing solution that could produce parts with the strength and durability of carbon fiber. This led to extensive research and development, focusing on overcoming the technical hurdles associated with printing with this material. The timeline below Artikels the key milestones in the development and launch of the Mark One:

- 2015: Research and development phase begins. The team focuses on material science, extrusion technology, and software development.

- 2016: Prototype development and testing. The team iterates on design and functionality, addressing challenges such as material flow, print quality, and bed adhesion.

- 2017: Initial public unveiling at a major industry trade show. The Mark One receives positive feedback from potential customers and industry experts.

- 2018: Commercial launch of the Mark One. The printer is available for purchase by businesses and research institutions.

- 2019: Ongoing development and improvement. The team continues to enhance the Mark One’s features and capabilities, based on user feedback and market trends.

Comparison with Other 3D Printers

The Mark One’s unique features and specifications set it apart from other contemporary 3D printers. The table below provides a comparison of the Mark One with other popular 3D printing technologies:

| Feature | Mark One | Fused Deposition Modeling (FDM) | Stereolithography (SLA) | Selective Laser Sintering (SLS) |

|---|---|---|---|---|

| Material | Carbon fiber | Thermoplastics | Photopolymer resins | Polymers, metals, ceramics |

| Resolution | High | Medium | High | Medium |

| Strength | High | Medium | Medium | High |

| Surface finish | Good | Fair | Excellent | Good |

| Cost | High | Low | Medium | High |

Factors Contributing to the Success of the Mark One

The success of the Mark One can be attributed to several key factors:

- First-mover advantage: The Mark One was the first 3D printer to offer carbon fiber printing capabilities, giving it a significant competitive edge.

- Strong market demand: There was a clear and growing demand for 3D printing solutions that could produce parts with the strength and durability of carbon fiber.

- Innovative technology: The Mark One’s unique design and advanced printing technology allowed it to overcome the challenges associated with printing with carbon fiber.

- Effective marketing and communication: The company successfully communicated the benefits of the Mark One to potential customers, highlighting its unique capabilities and the advantages it offered.

- Strong partnerships: The company forged strategic partnerships with key players in the carbon fiber industry, ensuring access to materials and expertise.

The mark one is the worlds first 3d printer that can print carbon fiber – The Mark One, with its ability to print carbon fiber, ushered in a new era of 3D printing. This wasn’t just about creating prototypes; it was about manufacturing high-performance parts that could withstand extreme conditions. From lightweight drones to medical implants, the Mark One’s impact was undeniable. It was a testament to the power of innovation and a glimpse into a future where 3D printing would play an even more significant role in shaping our world.

The Mark One is a game-changer in the world of 3D printing, being the first to print with carbon fiber. It’s like having a mini-factory at your fingertips, building everything from drones to car parts. While the Mark One is pushing boundaries in manufacturing, Verizon is pushing boundaries in tech accessibility with their 50% discount on Moto Mods, verizon discounting moto mods 50 percent.

This means you can get your hands on a powerful phone with customizable features at a fraction of the price. Whether you’re building the future with the Mark One or enhancing your phone with Moto Mods, innovation is all around us.

Standi Techno News

Standi Techno News