Mobile Fab Bicycle

Imagine a bicycle that not only transports you but also transforms your surroundings. The Mobile Fab Bicycle, a revolutionary concept, integrates 3D printing technology into a mobile platform, bringing the power of customization and creation directly to the streets.

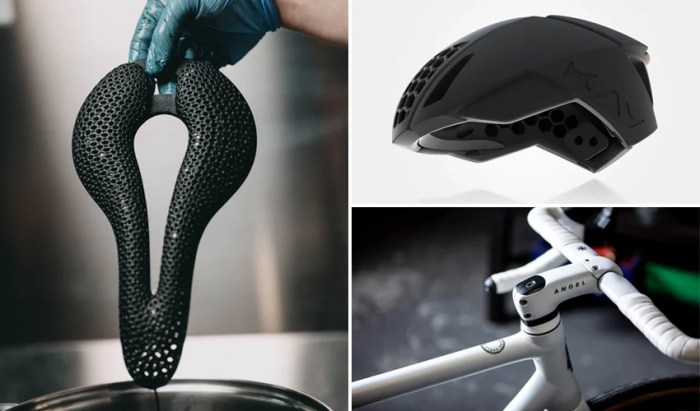

This innovative creation is designed to be a versatile and accessible tool for a variety of purposes. It features a compact 3D printer integrated into a custom-built bicycle frame, powered by a lightweight and efficient battery system. The printer is capable of producing a range of objects using various materials, including plastics, resins, and even bio-based materials.

Potential Benefits of Mobile 3D Printing

The Mobile Fab Bicycle offers a unique blend of accessibility, convenience, and customization, making it a game-changer for various industries and individuals.

- Accessibility: The mobile nature of the service eliminates the need for physical access to a fixed 3D printing facility, making it readily available to a wider audience. This is particularly beneficial in areas with limited access to traditional manufacturing facilities or for individuals who require on-demand printing solutions.

- Convenience: The Mobile Fab Bicycle brings the printing process directly to the user, eliminating the need for transportation and handling of materials. This convenience is particularly appealing for small-scale projects, prototyping, or emergency repairs, allowing for rapid turnaround times and efficient production.

- Customization: The Mobile Fab Bicycle empowers users to design and create personalized objects tailored to their specific needs. This opens up a world of possibilities for bespoke products, customized accessories, and personalized solutions, fostering creativity and innovation.

Target Audience and Applications

The Mobile Fab Bicycle caters to a diverse target audience, including individuals, businesses, and organizations seeking on-demand 3D printing solutions.

- Individuals: Hobbyists, artists, and makers can use the Mobile Fab Bicycle to create personalized objects, prototypes, and unique designs, pushing the boundaries of creativity and exploration.

- Businesses: Small and medium-sized enterprises (SMEs) can leverage the Mobile Fab Bicycle for rapid prototyping, product customization, and on-site repairs, enhancing efficiency and reducing lead times.

- Organizations: Non-profit organizations, educational institutions, and community groups can utilize the Mobile Fab Bicycle for outreach programs, workshops, and hands-on learning experiences, promoting STEM education and empowering communities.

Products and Services

The Mobile Fab Bicycle can produce a wide range of products and services, including:

- Prototypes and Models: Engineers, designers, and inventors can utilize the Mobile Fab Bicycle to create prototypes and models quickly and efficiently, accelerating the design and development process.

- Personalized Products: Consumers can customize products such as phone cases, jewelry, toys, and home decor, adding a personal touch to their belongings.

- Custom Parts and Repairs: The Mobile Fab Bicycle can be used to create replacement parts for machines, tools, or everyday objects, enabling on-site repairs and reducing downtime.

- Educational Tools: The Mobile Fab Bicycle can be used to create educational tools, models, and prototypes, fostering hands-on learning experiences in STEM fields.

3D Printing in Taiwan

Taiwan has emerged as a leading hub for 3D printing technology, with its adoption rapidly growing across various industries. This growth is fueled by government initiatives, robust manufacturing capabilities, and a thriving innovation ecosystem. The potential of 3D printing to revolutionize manufacturing, construction, and retail is significant, and Taiwan is well-positioned to capitalize on this emerging technology.

Adoption of 3D Printing in Taiwanese Industries

The adoption of 3D printing in Taiwan is evident in various sectors, including:

- Manufacturing: 3D printing is widely used for prototyping, tooling, and customized production in industries like automotive, electronics, and aerospace. Taiwan’s strong manufacturing base and skilled workforce make it ideal for implementing 3D printing solutions.

- Construction: 3D printing is transforming construction by enabling the creation of complex and customized building structures. This technology is used to print concrete structures, prefabricated components, and even entire houses, offering efficiency and cost savings.

- Healthcare: 3D printing is used in healthcare for creating customized medical devices, prosthetics, and anatomical models. This technology is also employed in drug development and personalized medicine, showcasing its potential to revolutionize healthcare practices.

- Retail: 3D printing is used for creating customized products, personalized gifts, and on-demand manufacturing in retail. This technology is enabling retailers to offer unique products and enhance customer experiences.

Impact of Mobile 3D Printing on the Taiwanese Market, Mobile fab bicycle delivers 3d printing on taiwans streets

Mobile 3D printing, as exemplified by the Mobile Fab Bicycle, offers several advantages that could significantly impact the Taiwanese market:

- On-Demand Manufacturing: Mobile 3D printing allows for on-site production, reducing lead times and transportation costs. This is particularly beneficial for industries like construction, where materials can be printed directly at the construction site.

- Customization and Personalization: Mobile 3D printing enables the creation of customized products tailored to specific needs. This can be valuable for retailers, allowing them to offer personalized goods and services.

- Decentralized Production: Mobile 3D printing promotes decentralized production, enabling small businesses and individuals to access manufacturing capabilities. This can empower local communities and foster entrepreneurship.

Comparison with Existing 3D Printing Solutions

The Mobile Fab Bicycle’s 3D printing capabilities are unique in Taiwan, offering a mobile and accessible solution compared to traditional stationary 3D printers. Existing 3D printing solutions in Taiwan typically involve large, stationary machines requiring dedicated facilities and skilled operators. The Mobile Fab Bicycle, on the other hand, is compact, portable, and user-friendly, making it suitable for various applications and environments.

The Mobile Fab Bicycle’s ability to bring 3D printing directly to the streets of Taiwan has the potential to democratize access to this technology, fostering innovation and entrepreneurship in new and exciting ways.

The Potential of Mobile 3D Printing for Urban Environments

Imagine a world where your broken bike seat can be repaired on the spot, or where you can customize your furniture with a 3D printed design. This is the promise of mobile 3D printing, a technology that has the potential to revolutionize how we live and interact with our urban environments. By bringing the power of 3D printing directly to the streets, mobile 3D printing can address a wide range of challenges and opportunities, fostering a more sustainable, personalized, and adaptable urban landscape.

Benefits of Mobile 3D Printing in Urban Environments

Mobile 3D printing offers a unique set of advantages that can directly benefit urban environments. It empowers local communities by enabling on-demand manufacturing and customization, reducing reliance on centralized production facilities and minimizing transportation costs.

- Reduced Waste: Mobile 3D printing can significantly reduce waste by enabling the creation of objects on demand, eliminating the need for large-scale production and subsequent disposal. This aligns with the principles of a circular economy, promoting resource efficiency and minimizing environmental impact.

- Enhanced Sustainability: By facilitating localized production, mobile 3D printing minimizes the carbon footprint associated with transportation and manufacturing. This aligns with efforts to create more sustainable urban environments and reduce greenhouse gas emissions.

- Personalized Solutions: Mobile 3D printing allows for the creation of custom-designed objects, tailored to individual needs and preferences. This fosters a more personalized and user-centric approach to design and production, enhancing the overall user experience and fostering innovation.

Challenges of Integrating Mobile 3D Printing into Urban Environments

While mobile 3D printing holds immense potential, integrating it into urban environments presents a number of challenges that need to be addressed.

- Regulations and Safety: Integrating mobile 3D printing into public spaces requires careful consideration of regulations and safety concerns. This includes ensuring compliance with local building codes, fire safety standards, and environmental regulations. The use of materials and the potential for accidental emissions also need to be carefully assessed.

- Infrastructure and Accessibility: The availability of reliable power sources, internet connectivity, and appropriate infrastructure is crucial for the successful deployment of mobile 3D printing units. Ensuring equitable access to these resources is essential to avoid exacerbating existing inequalities.

- Skill Development and Training: The adoption of mobile 3D printing requires a skilled workforce capable of operating and maintaining the technology. This necessitates targeted training programs and educational initiatives to equip individuals with the necessary knowledge and skills.

Potential Use Cases for Mobile 3D Printing in Urban Areas

The potential applications of mobile 3D printing in urban environments are vast and diverse, spanning various sectors and industries.

- On-Demand Repairs: Mobile 3D printing can be used for on-demand repairs of infrastructure, appliances, and other objects. This can significantly reduce downtime, minimize waste, and extend the lifespan of products, leading to cost savings and increased efficiency.

- Customized Goods: Mobile 3D printing can enable the creation of personalized goods, such as custom-fit footwear, prosthetics, and jewelry. This allows for greater customization and personalization, enhancing user experience and fostering a more inclusive and accessible design approach.

- Temporary Structures: Mobile 3D printing can be used to create temporary structures, such as pop-up shops, shelters, and event installations. This provides a flexible and sustainable alternative to traditional construction methods, allowing for rapid deployment and adaptation to changing needs.

The Future of Mobile Fab Bicycles: Mobile Fab Bicycle Delivers 3d Printing On Taiwans Streets

The Mobile Fab Bicycle, a revolutionary concept merging 3D printing with bicycle mobility, is poised to reshape urban landscapes and manufacturing practices. Its potential extends beyond merely printing objects; it holds the key to a decentralized, on-demand manufacturing future.

Advancements in 3D Printing Technology, Materials, and Design

Advancements in 3D printing technology, materials, and design will play a pivotal role in shaping the future of mobile fab bicycles. These advancements will lead to increased printing speeds, enhanced material properties, and more intricate designs.

- Faster Printing Speeds: The development of faster printing technologies like multi-jet fusion and vat polymerization will enable mobile fab bicycles to produce objects more efficiently, allowing for the creation of more complex and larger items within a shorter timeframe. This will enhance the practicality of mobile fab bicycles for on-demand manufacturing and repair services.

- Advanced Materials: The introduction of new 3D printing materials, such as high-strength composites and bio-based polymers, will broaden the range of applications for mobile fab bicycles. These materials will enable the production of objects with enhanced durability, functionality, and sustainability, paving the way for the creation of innovative products and solutions.

- Improved Design Capabilities: Advances in 3D printing software and design tools will empower users to create more intricate and complex designs. This will allow mobile fab bicycles to produce customized products tailored to specific needs and preferences. The integration of artificial intelligence and machine learning algorithms will further enhance design capabilities, enabling the creation of optimized designs for specific applications.

Impact on the Manufacturing Industry and the Future of Work

The widespread adoption of mobile fab bicycles will disrupt the traditional manufacturing landscape, leading to a shift towards decentralized, on-demand production.

- Decentralized Manufacturing: Mobile fab bicycles will enable the creation of localized manufacturing hubs, eliminating the need for centralized factories and long supply chains. This will foster greater economic independence and empower local communities to produce goods and services tailored to their specific needs.

- On-Demand Production: Mobile fab bicycles will facilitate on-demand production, allowing for the creation of customized products and solutions tailored to individual needs. This will enable businesses to respond quickly to market demands and cater to niche markets.

- Evolution of Work: The rise of mobile fab bicycles will create new job opportunities in design, manufacturing, and repair. It will also require workers to adapt to new skill sets, such as 3D printing operation, design software, and repair expertise. This will lead to a more diverse and adaptable workforce.

Social and Economic Implications of Widespread Adoption

The widespread adoption of mobile fab bicycles has the potential to transform urban environments and economies, leading to increased accessibility, reduced waste, and enhanced economic opportunities.

- Increased Accessibility: Mobile fab bicycles will provide individuals and communities with greater access to manufacturing capabilities, empowering them to create their own products and solutions. This will foster innovation and entrepreneurship, particularly in underserved communities.

- Reduced Waste: Mobile fab bicycles will enable the creation of products on demand, reducing the need for mass production and minimizing waste. This will contribute to a more sustainable and circular economy.

- Economic Opportunities: The widespread adoption of mobile fab bicycles will create new economic opportunities for individuals and communities. This will lead to the emergence of new businesses, jobs, and industries.

Mobile fab bicycle delivers 3d printing on taiwans streets – The Mobile Fab Bicycle is more than just a technological marvel; it’s a symbol of innovation, accessibility, and the potential of 3D printing to revolutionize urban living. As this revolutionary concept gains momentum, it’s exciting to imagine the future of 3D printing, where customized solutions and on-demand manufacturing are just a bike ride away. The streets of Taiwan are becoming a testing ground for this exciting new technology, and the results are promising. This mobile marvel has the potential to change the way we think about manufacturing, repair, and even the very fabric of our cities.

Imagine cruising through Taiwan’s bustling streets on a bicycle that doubles as a 3D printing workshop! This isn’t a sci-fi movie, it’s the reality of the mobile fab bicycle, a revolutionary concept that brings printing power to the people. But even the most cutting-edge tech can’t escape the timeless question of water resistance – check out this iphone 7 galaxy s7 underwater test to see how these smartphones fare in the deep end.

Back to the mobile fab bicycle, the potential for on-demand, personalized creations is truly exciting, turning everyday streets into a playground for innovation.

Standi Techno News

Standi Techno News