Audi Synthetic Gasoline Plants: Imagine a world where your car runs on fuel made from thin air, literally. That’s the ambitious vision Audi is pursuing with its investment in synthetic gasoline plants. This innovative approach aims to decarbonize transportation, offering a potential solution to our reliance on fossil fuels.

Audi’s synthetic gasoline initiative isn’t just about cleaner cars; it’s a strategic move to achieve carbon neutrality. By harnessing renewable energy sources, they’re creating a sustainable fuel that can be used in existing combustion engines. This opens up possibilities for reducing emissions without requiring a complete overhaul of our automotive infrastructure.

Audi’s Synthetic Gasoline Initiative: Audi Synthetic Gasoline Plants

Audi, a renowned German automotive manufacturer, has embarked on a groundbreaking initiative to invest in synthetic gasoline plants. This strategic move reflects the company’s commitment to achieving carbon neutrality and addressing the growing concerns surrounding climate change.

The Motivation Behind Audi’s Investment

Audi’s investment in synthetic gasoline plants is driven by a multifaceted motivation, encompassing environmental responsibility, technological innovation, and market adaptability. The company recognizes the urgent need to reduce greenhouse gas emissions from the transportation sector, particularly from internal combustion engines (ICE). Synthetic gasoline, also known as e-fuels, presents a viable solution by offering a carbon-neutral alternative to conventional fossil fuels.

The Role of E-fuels in Audi’s Strategy

E-fuels play a crucial role in Audi’s broader strategy for achieving carbon neutrality. While the company is actively developing and promoting electric vehicles (EVs), it acknowledges that ICE vehicles will continue to be a significant part of the automotive landscape for the foreseeable future. E-fuels provide a bridge between the present and the future, enabling the continued use of ICE vehicles without compromising environmental sustainability.

Key Partnerships and Collaborations, Audi synthetic gasoline plants

Audi has forged strategic partnerships and collaborations to advance its synthetic gasoline initiative. These partnerships involve technology providers, energy companies, and research institutions, pooling expertise and resources to accelerate the development and deployment of e-fuels.

- Audi has partnered with the German energy company, RWE, to develop a large-scale synthetic gasoline plant in Germany. This collaboration aims to establish a robust production and distribution infrastructure for e-fuels.

- Audi has also collaborated with the Porsche Engineering Group to develop a pilot plant for the production of synthetic gasoline. This partnership leverages the combined technical expertise of both companies to refine and optimize the production process.

Synthetic Gasoline Production Technology

Synthetic gasoline, also known as e-fuels, is a fuel produced from renewable sources, offering a potential solution to reduce carbon emissions in the transportation sector. This innovative technology harnesses the power of renewable energy to create a fuel that can be used in existing gasoline engines, making it a viable alternative to traditional fossil fuels.

Production Methods

Several methods are employed to produce synthetic gasoline from renewable sources. Each method has its unique advantages and disadvantages, influencing its feasibility and environmental impact.

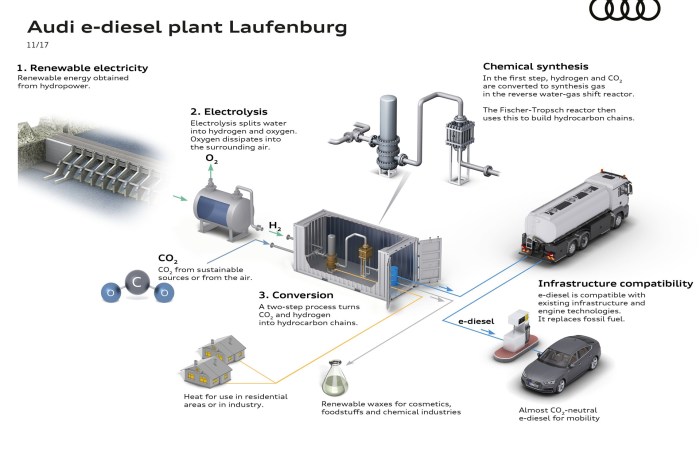

- Power-to-Liquid (PtL): This method involves using renewable electricity to produce hydrogen through electrolysis of water. The hydrogen is then combined with carbon dioxide, captured from the atmosphere or industrial processes, to create synthetic hydrocarbons, including gasoline. PtL is a promising method due to its high efficiency and potential for carbon neutrality. However, the high energy consumption and cost of electrolysis remain challenges.

- Fischer-Tropsch Synthesis: This method uses synthesis gas, a mixture of carbon monoxide and hydrogen, to produce synthetic hydrocarbons. Synthesis gas can be derived from various sources, including biomass, natural gas, and coal. Fischer-Tropsch synthesis offers flexibility in feedstock and can produce a wide range of fuels, including gasoline. However, it requires high temperatures and pressures, leading to high energy consumption and potential environmental concerns.

- Biomass-to-Liquids (BtL): This method uses biomass, such as wood or agricultural waste, as a feedstock. The biomass is gasified to produce synthesis gas, which is then converted into synthetic hydrocarbons using Fischer-Tropsch synthesis. BtL offers a sustainable alternative to fossil fuels, using renewable biomass as a source. However, it requires efficient biomass harvesting and processing techniques to minimize environmental impact.

Technological Challenges and Advancements

The production of synthetic gasoline faces several technological challenges, including:

- Cost-Effectiveness: The production of synthetic gasoline currently remains more expensive than conventional gasoline. Continued research and development are crucial to improve efficiency and reduce production costs.

- Scale-Up: Scaling up synthetic gasoline production to meet the global demand for transportation fuel requires significant investments and technological advancements. Research efforts are focused on developing efficient and scalable production technologies.

- Integration with Existing Infrastructure: Integrating synthetic gasoline into the existing fuel distribution infrastructure requires adjustments and modifications. Research and development are ongoing to ensure seamless compatibility with existing systems.

Despite these challenges, advancements in technology are paving the way for a more sustainable future for the transportation sector. Research and development efforts are focused on:

- Improving Efficiency: Researchers are working on developing more efficient and cost-effective production methods, including optimizing catalysts and reactor designs.

- Renewable Feedstock: Efforts are underway to explore alternative renewable feedstock sources, such as algae and municipal waste, to enhance sustainability.

- Carbon Capture and Storage: Technological advancements in carbon capture and storage are crucial to minimize the environmental impact of synthetic gasoline production.

Benefits and Drawbacks of Synthetic Gasoline

Synthetic gasoline, also known as e-fuels, is a fuel produced from non-biological sources, such as carbon dioxide and hydrogen. This technology offers a potential solution to reduce greenhouse gas emissions from the transportation sector while maintaining compatibility with existing infrastructure and internal combustion engines.

Environmental Benefits of Synthetic Gasoline

Synthetic gasoline holds the potential to significantly reduce greenhouse gas emissions compared to conventional gasoline derived from fossil fuels. The production process involves capturing carbon dioxide from the atmosphere or industrial sources, which is then converted into synthetic fuel using renewable energy sources.

- Carbon Neutrality: By capturing carbon dioxide during the production process, synthetic gasoline can achieve carbon neutrality. This means that the net emissions associated with its production and combustion are zero, effectively mitigating the contribution to climate change.

- Reduced Emissions: Synthetic gasoline can significantly reduce emissions of harmful pollutants, such as particulate matter, nitrogen oxides, and sulfur dioxide, compared to conventional gasoline. This leads to improved air quality and reduced health risks associated with air pollution.

- Sustainable Fuel Source: Synthetic gasoline can be produced from renewable sources, such as solar, wind, and hydro power, making it a sustainable fuel alternative to fossil fuels. This helps to reduce dependence on finite resources and promotes energy independence.

Economic Feasibility and Scalability of Synthetic Gasoline Production

The economic feasibility and scalability of synthetic gasoline production are critical factors determining its widespread adoption. The current production costs for synthetic gasoline are higher than those for conventional gasoline, but technological advancements and economies of scale have the potential to reduce these costs.

- High Production Costs: Currently, the production of synthetic gasoline is significantly more expensive than conventional gasoline. This is primarily due to the high energy requirements and the need for advanced technologies for carbon capture and conversion.

- Economies of Scale: As the demand for synthetic gasoline increases, economies of scale can help to reduce production costs. Large-scale production facilities can optimize processes, reduce operating costs, and benefit from lower input prices.

- Technological Advancements: Continuous research and development are driving advancements in synthetic gasoline production technologies, leading to increased efficiency and reduced costs. Innovations in carbon capture, energy storage, and catalytic conversion processes hold the potential to make synthetic gasoline production more cost-effective.

Impact of Synthetic Gasoline on the Automotive Industry and Energy Sector

The introduction of synthetic gasoline could have significant implications for the automotive industry and the energy sector. It offers an opportunity to maintain the existing infrastructure and vehicle fleet while transitioning towards a more sustainable transportation system.

- Extended Lifespan of Internal Combustion Engines: Synthetic gasoline provides a pathway to extend the lifespan of existing internal combustion engines, offering a more gradual transition towards electric vehicles. This can be particularly beneficial for developing countries with large fleets of older vehicles.

- New Market Opportunities: The production and distribution of synthetic gasoline can create new market opportunities for companies in the automotive, energy, and chemical industries. This could lead to job creation and economic growth in these sectors.

- Energy Sector Transformation: Synthetic gasoline production requires significant amounts of renewable energy, potentially driving a shift towards a more sustainable energy sector. This could lead to investments in renewable energy infrastructure and the development of new energy technologies.

Audi’s Synthetic Gasoline Plants

Audi’s synthetic gasoline plants are a testament to the company’s commitment to sustainability and innovation in the automotive industry. These plants utilize advanced technologies to produce e-fuels, offering a promising alternative to traditional gasoline derived from fossil fuels.

Audi’s Synthetic Gasoline Plants: Case Studies

To understand the practical implications of Audi’s synthetic gasoline initiative, it’s essential to examine specific case studies of their operational plants.

Locations and Operational Details

Audi has partnered with various entities to establish synthetic gasoline production facilities around the world. These plants vary in size and capacity, but they share a common goal of producing sustainable e-fuels. Here are some notable examples:

- e-benzin plant in Werlte, Germany: This facility, established in collaboration with the energy company RWE, has a production capacity of approximately 13,000 tons of e-fuel per year. The plant utilizes renewable energy sources like wind power to produce hydrogen, which is then combined with captured CO2 to create synthetic gasoline.

- Collaboration with Porsche: Audi has joined forces with Porsche to develop a large-scale synthetic gasoline plant in Chile. This project aims to leverage the country’s abundant renewable energy resources to produce e-fuels on a significant scale. The plant is expected to have a production capacity of up to 550,000 tons of e-fuel per year, contributing to the development of a sustainable fuel infrastructure in the region.

Environmental and Economic Impact

Audi’s synthetic gasoline plants are designed to have a positive environmental impact by reducing greenhouse gas emissions. By using renewable energy sources and capturing CO2, these facilities aim to create a closed-loop system that minimizes the carbon footprint of transportation.

The economic impact of these plants is multifaceted. They create new jobs in the renewable energy and fuel production sectors, contributing to local economic growth. Moreover, the development of e-fuel infrastructure could stimulate innovation and investment in sustainable technologies.

Real-World Applications

Audi’s synthetic gasoline is being utilized in real-world applications, showcasing its potential to contribute to a cleaner and more sustainable future. Here are some examples:

- Audi e-tron GT: Audi’s electric performance car, the e-tron GT, can be powered by synthetic gasoline, demonstrating the compatibility of e-fuels with existing internal combustion engines. This allows drivers to enjoy the performance of a high-performance vehicle while reducing their carbon footprint.

- Racing: Audi’s e-fuels are being used in motorsport, where they provide a sustainable alternative to traditional fossil fuels. For example, the Audi R8 LMS GT3 race car has been successfully tested with synthetic gasoline, showcasing its performance capabilities.

Future Prospects for Synthetic Gasoline

Synthetic gasoline has the potential to play a significant role in decarbonizing the transportation sector, particularly in areas where electrification is challenging, such as long-haul trucking or aviation. It offers a pathway to reducing greenhouse gas emissions from internal combustion engines (ICE) while leveraging existing infrastructure and vehicles.

Scaling Up Synthetic Gasoline Production

Scaling up synthetic gasoline production presents both challenges and opportunities. To meet the demands of a global transportation system, significant investments in production capacity and infrastructure are required.

- Cost-effectiveness: The current production cost of synthetic gasoline is higher than conventional gasoline. Reducing production costs through process optimization, economies of scale, and technological advancements is crucial for wider adoption.

- Renewable Energy Sources: The sustainability of synthetic gasoline relies on the availability of renewable energy sources to power its production. Expanding renewable energy infrastructure and developing efficient energy storage solutions are critical for scaling up production.

- Policy Support: Government policies and incentives, such as carbon pricing mechanisms and subsidies, can play a significant role in stimulating investment in synthetic gasoline production and encouraging its adoption.

Technological Advancements in Synthetic Gasoline Production

Ongoing research and development efforts are focused on improving the efficiency and cost-effectiveness of synthetic gasoline production. These advancements include:

- Improved Catalysts: Developing more efficient catalysts can enhance the conversion of feedstock materials into synthetic gasoline, reducing energy consumption and production costs.

- Electrochemical Synthesis: Electrochemical processes using renewable electricity to convert CO2 and water into synthetic fuels offer a promising avenue for sustainable production.

- Integrated Production Systems: Integrating synthetic gasoline production with other industrial processes, such as renewable energy generation or carbon capture and storage, can improve overall efficiency and reduce costs.

Audi’s synthetic gasoline plants represent a bold leap towards a greener future. While there are challenges to overcome, the potential benefits are undeniable. From reducing our carbon footprint to creating a more sustainable energy sector, this initiative could reshape the landscape of transportation. The success of Audi’s venture will depend on technological advancements, cost-effectiveness, and the willingness of the industry to embrace this innovative fuel source.

Audi’s synthetic gasoline plants are a step towards a greener future, but they’re not the only innovative tech on the horizon. Meanwhile, AT&T is making waves in the tech world with its own tablet, the Trek HD 4G LTE, att launches its own tablet the trek hd 4g lte which could potentially revolutionize how we consume media and connect online.

Back to Audi, their synthetic gasoline plants are a promising solution to reducing our dependence on fossil fuels, and it’s exciting to see how these advancements will shape the future of transportation.

Standi Techno News

Standi Techno News