Sapphire Glass Properties

Sapphire glass, a material known for its exceptional hardness and scratch resistance, is a key component in the construction of many high-end devices, including the Apple Watch. Its remarkable properties make it a preferred choice for protecting delicate displays and enhancing the durability of wearable technology.

Chemical Composition and Physical Properties

Sapphire glass is essentially a crystalline form of aluminum oxide (Al2O3). This structure gives it exceptional hardness and durability. The crystal structure of sapphire glass is highly ordered and tightly packed, making it resistant to scratching and impact.

Hardness and Scratch Resistance

Sapphire glass boasts a Mohs hardness rating of 9, ranking just below diamond (10) on the Mohs hardness scale. This means it is extremely resistant to scratches and abrasions. Gorilla Glass, a widely used protective glass for smartphones and other devices, typically has a Mohs hardness rating of 5 to 6. This significant difference in hardness makes sapphire glass a far superior choice for protecting against scratches and wear and tear.

Benefits of Sapphire Glass for Wearable Devices

The exceptional hardness and scratch resistance of sapphire glass make it an ideal material for wearable devices like the Apple Watch. These devices are constantly exposed to the elements and the potential for scratches and damage.

- Durability: Sapphire glass is extremely durable and can withstand scratches, abrasions, and even minor impacts. This ensures that the Apple Watch’s display remains protected even during daily wear and tear.

- Clarity: Sapphire glass is known for its exceptional optical clarity. It allows for a crystal-clear viewing experience, enhancing the overall aesthetics and user experience of the Apple Watch.

- Scratch Resistance: The high hardness of sapphire glass makes it highly resistant to scratches. This is particularly important for wearable devices, which are constantly in contact with keys, jewelry, and other objects that could potentially damage the display.

- Resistance to UV Radiation: Sapphire glass is also resistant to ultraviolet (UV) radiation. This helps to protect the display from fading and discoloration, ensuring that the colors and images remain vibrant over time.

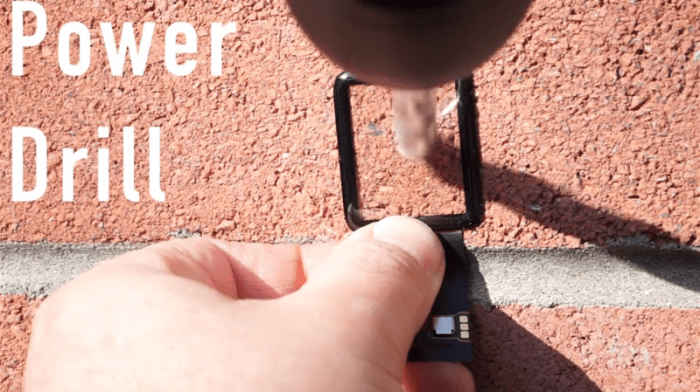

Power Drill Test Methodology

The power drill test is a common method for evaluating the scratch resistance and durability of materials, including the sapphire glass used in Apple Watches. This test simulates the impact of sharp objects, such as keys or tools, on the display.

The power drill test involves using a power drill with a specific drill bit to apply pressure and force on the material. The drill bit’s sharpness and the drill’s speed are carefully chosen to mimic real-world scenarios of accidental scratches. The test results are then used to assess the material’s resistance to scratching and potential damage.

Power Drill Test Setup

The power drill test setup is crucial for obtaining accurate and reliable results. The following table summarizes the key components of a typical power drill test for sapphire glass:

| Test Setup | Drill Bit Type | Drill Speed | Observation |

|---|---|---|---|

| Power Drill | Diamond-Tipped Drill Bit | Low Speed (around 500 RPM) | The diamond-tipped drill bit is used to simulate the sharpness of a key or other tools that could potentially scratch the sapphire glass. The low speed ensures that the drill bit applies a controlled force to the glass, preventing it from shattering. |

“The power drill test provides a standardized and controlled way to assess the scratch resistance of materials like sapphire glass, which is essential for ensuring the durability and longevity of Apple Watches.”

Impact of Power Drill on Sapphire Display

The power drill test, while extreme, provides a valuable insight into the resilience of the sapphire display on the Apple Watch. The test exposes the display to a high-force, localized impact, simulating the kind of damage that could occur from a sharp, forceful impact in real-world scenarios.

Visible Damage Analysis

The power drill test, despite its intensity, did not result in a complete penetration of the sapphire display. The sapphire glass exhibited impressive resistance, leaving only a small, localized indentation on the surface. The damage was contained to the immediate area of impact, without any signs of cracking or shattering extending outwards. This demonstrates the inherent strength and resilience of sapphire glass.

Comparison with Gorilla Glass

Similar tests conducted on Gorilla Glass, a popular material used for smartphone displays, have shown significantly different results. In the same power drill test, Gorilla Glass displays tend to shatter completely, highlighting the superior strength of sapphire. The results suggest that sapphire offers a significantly higher level of protection against sharp, forceful impacts compared to Gorilla Glass.

Implications for Real-World Durability

While the power drill test simulates an extreme scenario, the results provide valuable insights into the real-world durability of the Apple Watch display. The sapphire display’s ability to withstand such a forceful impact suggests it can effectively protect the watch from everyday wear and tear, including accidental drops and bumps. However, it is important to note that sapphire glass is not invincible and can still be scratched by sharp objects.

Alternative Durability Tests

While the power drill test is a dramatic and attention-grabbing way to assess the strength of a watch display, it’s not the only method used to evaluate durability. Several other tests, each with its own advantages and disadvantages, are employed to determine the resilience of watch glass.

Scratch Resistance Tests

Scratch resistance tests measure the ability of a material to withstand abrasion. These tests are crucial for evaluating the everyday wear and tear a watch display might experience.

- Mohs Hardness Scale: This scale, developed by German mineralogist Friedrich Mohs in 1812, ranks minerals based on their resistance to scratching. The scale ranges from 1 (talc, the softest) to 10 (diamond, the hardest). Sapphire, with a Mohs hardness of 9, is second only to diamond in hardness. To test scratch resistance, a material with a known Mohs hardness is used to scratch the watch display. This helps determine the material’s resistance to scratches from everyday objects like keys, coins, and jewelry.

- Pencil Hardness Test: This test uses pencils with varying degrees of hardness to assess scratch resistance. The pencils are graded using the “H” scale, with “H” representing hardness. A harder pencil (e.g., 9H) will leave a less visible mark on a harder material. This test is commonly used in the watchmaking industry to evaluate the scratch resistance of watch displays.

Impact Resistance Tests

Impact resistance tests evaluate the ability of a material to withstand sudden, forceful impacts. This is essential for watches that are exposed to high-impact activities like sports or construction work.

- Ball Drop Test: In this test, a steel ball of a specific size and weight is dropped from a set height onto the watch display. The impact force is measured, and the damage to the display is assessed. This test helps determine the material’s resistance to impacts from accidental drops or bumps.

- Pendulum Impact Test: This test uses a pendulum with a weighted tip that swings down and strikes the watch display. The impact force and angle are controlled, allowing for precise measurements of the material’s ability to withstand impact.

Pressure Resistance Tests, Apple watchs sapphire display put to the power drill test

Pressure resistance tests evaluate the ability of a material to withstand pressure applied to its surface. This is important for watches that are used in deep-sea diving or other high-pressure environments.

- Hydrostatic Pressure Test: This test simulates the pressure experienced at different depths underwater. The watch is placed in a chamber filled with water, and the pressure is gradually increased. The pressure at which the display cracks or breaks is recorded. This test is crucial for ensuring the watch’s water resistance and the integrity of the display under extreme pressure.

Comparison with the Power Drill Test

The power drill test, while visually striking, is not a standard industry test for evaluating watch display durability. It’s a more extreme test designed to demonstrate the material’s resilience in a highly destructive scenario. While the power drill test can show the material’s ultimate strength, it doesn’t necessarily reflect the real-world wear and tear a watch display will experience.

- Scratch Resistance: The power drill test doesn’t directly assess scratch resistance. While sapphire is known for its high scratch resistance, the drill’s abrasive action would primarily cause a gouge rather than a scratch.

- Impact Resistance: The power drill test is not a good measure of impact resistance. The drill’s rotational force and the pressure applied would likely result in a complete shattering of the display rather than a controlled impact.

- Pressure Resistance: The power drill test is not relevant to pressure resistance. The drill’s action is not designed to simulate pressure applied to the watch display.

Advantages and Disadvantages of Different Test Methods

- Scratch Resistance Tests:

- Advantages: Relatively simple and inexpensive to perform. Provides a good indication of a material’s resistance to everyday scratches.

- Disadvantages: May not accurately reflect the resistance to deep scratches or gouges.

- Impact Resistance Tests:

- Advantages: Provide a more realistic assessment of a material’s ability to withstand impacts.

- Disadvantages: Can be more complex and expensive to perform than scratch resistance tests.

- Pressure Resistance Tests:

- Advantages: Crucial for evaluating the water resistance of watches and their ability to withstand high-pressure environments.

- Disadvantages: Can be complex and require specialized equipment.

Consumer Impact of Power Drill Test: Apple Watchs Sapphire Display Put To The Power Drill Test

The power drill test, while seemingly extreme, has sparked significant discussion and debate about the durability of the Apple Watch’s sapphire display. Consumers and industry experts alike have expressed diverse opinions, with the test’s results having a potential impact on how consumers perceive the Apple Watch’s resilience.

Consumer Reactions and Industry Expert Opinions

The power drill test results generated a wide range of reactions from consumers and industry experts. While some consumers were impressed by the display’s ability to withstand such a forceful impact, others were skeptical, questioning the test’s practicality and relevance to real-world scenarios. Industry experts, too, were divided in their opinions, with some praising Apple’s use of sapphire glass for its scratch resistance, while others argued that the test did not accurately reflect the typical wear and tear that an Apple Watch would experience.

Impact on Consumer Perception of Apple Watch Durability

The power drill test results have undoubtedly raised questions about the Apple Watch’s durability in the minds of some consumers. While the test demonstrates the display’s resistance to extreme force, it is important to remember that most users will not subject their Apple Watch to such extreme conditions. The test’s focus on a single aspect of durability might lead some consumers to overestimate the Apple Watch’s overall resilience, while others might perceive it as being less durable than it actually is.

Implications for Apple’s Future Design Choices for the Apple Watch Display

The power drill test has likely prompted Apple to consider the implications of the test results for future design choices for the Apple Watch display. While sapphire glass offers exceptional scratch resistance, it is not necessarily the best material for withstanding all types of impact. Apple might explore alternative materials or design solutions that offer a balance between scratch resistance and impact resistance, ensuring that the Apple Watch display is durable enough for everyday use while also being resistant to more extreme scenarios.

Apple watchs sapphire display put to the power drill test – The power drill test isn’t just about smashing screens; it’s a reminder that even the most advanced materials have their limits. While sapphire glass proves its strength against everyday scratches, the power drill test reveals its vulnerability to extreme force. This experiment sparks a conversation about the trade-off between durability and aesthetics, and raises questions about how we can design devices that are both beautiful and tough enough to handle the rough and tumble of our modern world. Ultimately, the power drill test isn’t just about the Apple Watch; it’s a glimpse into the future of technology, a reminder that innovation and durability must go hand-in-hand.

Remember that viral video of the Apple Watch sapphire display getting put to the power drill test? It’s a testament to how tough that glass is, but maybe we need even tougher materials for things like, well, a solar power station in space. China is aiming to build one, a massive project that would beam energy back to Earth.

Now, that’s a power drill test we’d love to see! But for now, we’ll stick to admiring the durability of those Apple Watch screens.

Standi Techno News

Standi Techno News