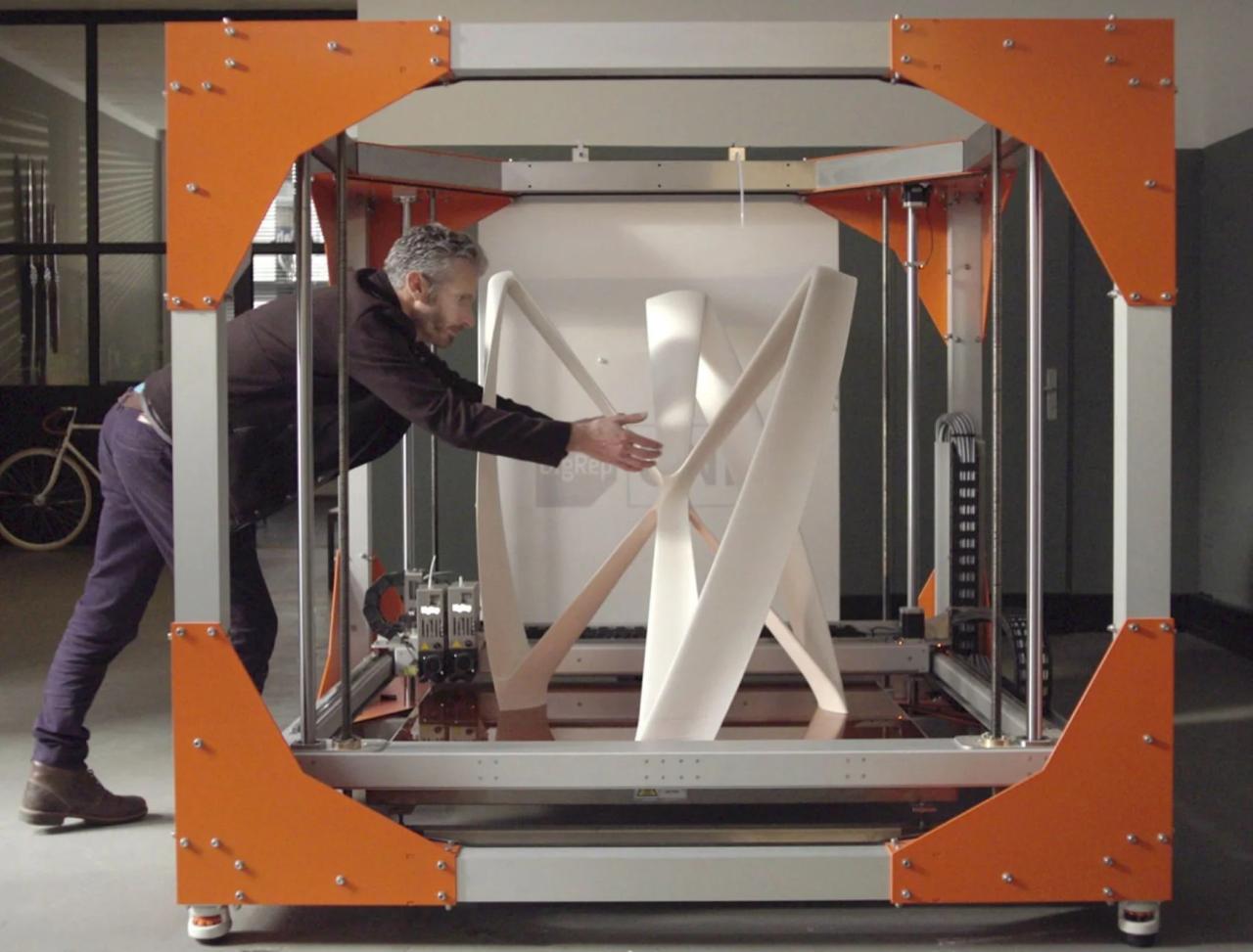

The Scale of BigRep 3D Printers

BigRep 3D printers stand out in the world of additive manufacturing with their impressive size. While most consumer-grade 3D printers are confined to a small desktop footprint, BigRep machines can handle significantly larger projects. Their industrial-grade build volumes allow them to print objects that would be impossible for smaller printers, making them a game-changer for various applications.

The Advantages of Large-Scale 3D Printing

The ability to print objects on a massive scale opens up a world of possibilities. Here are some key advantages of using BigRep 3D printers for large-scale projects:

- Large-scale prototyping: Imagine being able to print a full-size prototype of a car part or a piece of furniture. This allows for detailed design exploration and testing before committing to expensive tooling and production.

- Customization and personalization: With BigRep printers, you can create custom furniture, architectural models, or even entire building facades. This level of personalization allows for unique and tailored designs that are impossible to achieve with traditional manufacturing methods.

- Reduced lead times: BigRep printers can quickly produce large objects, reducing the time required for traditional manufacturing processes. This can be particularly beneficial for projects with tight deadlines or for producing custom parts on demand.

- Simplified production: BigRep printers can eliminate the need for multiple molds or complex assembly processes, simplifying the production of large objects. This can lead to significant cost savings and improved efficiency.

Applications of BigRep 3D Printers for Table Production

The ability of BigRep 3D printers to create large-scale objects opens up a world of possibilities for table production. These printers, with their capacity to handle massive materials, are not just limited to creating furniture pieces for homes. They can be used to produce custom-designed tables for various industries and settings, each tailored to specific needs and aesthetic preferences.

Industries Where Large-Scale 3D Printing of Tables is Relevant

The use of BigRep 3D printers for table production is not confined to a single industry. Their applications span across diverse sectors, each benefiting from the unique capabilities of large-scale 3D printing.

- Retail and Hospitality: BigRep 3D printers can be utilized to create eye-catching and functional tables for retail spaces and restaurants. These tables can be customized with intricate designs, brand logos, or even integrated lighting features, enhancing the overall aesthetic and brand identity of the establishment.

- Education and Research: Large-scale 3D printing allows for the creation of highly specialized tables for educational institutions and research labs. These tables can be designed with integrated storage compartments, specialized work surfaces, or even complex geometries to accommodate specific experiments or learning activities.

- Healthcare: The use of BigRep 3D printers in healthcare extends beyond the creation of medical devices. They can be used to produce customized tables for hospitals, clinics, and rehabilitation centers. These tables can be designed to accommodate patients with specific needs, such as adjustable heights, integrated handrails, or specialized surfaces for wheelchair access.

- Architecture and Design: BigRep 3D printers offer architects and designers a powerful tool for creating unique and functional tables. These tables can be incorporated into public spaces, museums, or even private residences, adding a distinctive touch to the environment.

- Industrial and Manufacturing: BigRep 3D printers can be used to create sturdy and durable tables for industrial settings. These tables can be designed to withstand heavy loads, resist wear and tear, and provide ample workspace for various manufacturing tasks.

Examples of Custom Table Designs

The flexibility of BigRep 3D printers allows for the creation of tables with unique designs and functionalities, catering to specific needs and preferences.

- Multi-functional Table: A table designed with integrated storage compartments, a built-in charging station, and a retractable display screen, offering a combination of functionality and aesthetic appeal.

- Organic Design Table: A table inspired by natural forms, with flowing lines and intricate details, showcasing the artistic capabilities of 3D printing.

- Interactive Table: A table equipped with touch-sensitive surfaces and integrated sensors, allowing for interactive experiences and multimedia displays.

- Lightweight Table: A table designed for portability and ease of movement, with a lightweight construction and integrated handles.

- Sustainable Table: A table made from recycled materials or bio-based plastics, promoting sustainability and environmental consciousness.

Potential Uses for 3D Printed Tables in Various Settings

BigRep 3D printed tables find their place in various settings, offering unique solutions for different needs.

- Home: 3D printed tables can enhance the aesthetics and functionality of living spaces, offering custom designs, integrated features, and unique finishes to complement the overall decor.

- Office: These tables can provide ergonomic workspaces, with adjustable heights, integrated cable management systems, and customizable surfaces to optimize productivity.

- Public Spaces: BigRep 3D printed tables can be used in parks, plazas, and other public areas, offering durable, weather-resistant, and aesthetically pleasing furniture solutions.

Materials and Printing Processes for Table Production

The selection of materials and the printing processes employed are critical in the creation of large-scale 3D printed objects, like tables. BigRep 3D printers are capable of utilizing a variety of materials, each offering unique properties and suitability for specific applications.

Material Selection for Table Production, Bigrep 3d printer is huge enough to deliver a whole table

The choice of materials for table production depends on factors like desired aesthetics, strength, durability, and cost. Here are some commonly used materials for large-scale 3D printing:

- Polyamide (PA): Also known as nylon, PA is a strong, durable, and versatile material with excellent impact resistance. It is often used in industrial applications and can withstand high temperatures. It is commonly used for furniture parts, due to its high strength-to-weight ratio and resistance to wear and tear.

- Polypropylene (PP): PP is a lightweight and flexible material with good chemical resistance. It is often used for food-grade applications and is also recyclable. This material is a good option for tables intended for outdoor use, as it can withstand exposure to the elements.

- Polyethylene (PE): PE is a versatile material with excellent resistance to chemicals and moisture. It is commonly used for packaging and is available in different densities. It is a good option for tables requiring high impact resistance, as it is also a flexible material.

- Acrylonitrile Butadiene Styrene (ABS): ABS is a strong, rigid, and impact-resistant material. It is often used for prototypes and functional parts, due to its ease of printing and durability. ABS is also a good choice for tables that require a smooth finish, as it can be easily sanded and painted.

- Polycarbonate (PC): PC is a strong, transparent material with excellent impact resistance and high heat resistance. It is often used for safety glasses and automotive parts, and it is also a good choice for tables that need to be durable and resistant to scratches.

- Wood-based Filaments: These filaments are made from wood fibers mixed with a thermoplastic polymer, providing a natural look and feel. They are becoming increasingly popular for furniture applications due to their sustainable nature and aesthetic appeal. These materials offer a unique blend of natural beauty and durability.

- Composite Materials: Composites like carbon fiber reinforced plastic (CFRP) or glass fiber reinforced plastic (GFRP) can be used for 3D printing tables, providing high strength and stiffness, and lightweight construction. These materials are often used in high-performance applications, such as aerospace and automotive industries.

Printing Processes for Table Production

BigRep 3D printers utilize a process called fused deposition modeling (FDM), also known as fused filament fabrication (FFF), to create objects layer by layer. In this process, a thermoplastic filament is heated and extruded through a nozzle, depositing the material onto a build platform. The nozzle moves back and forth, laying down successive layers, gradually building up the 3D object.

- Layer Deposition: The printing process begins with the deposition of the first layer of material on the build platform. This layer is typically a thin, flat sheet that serves as the foundation for the rest of the object.

- Layer-by-Layer Build: The nozzle then moves to the next layer, depositing material on top of the previous layer. This process is repeated until the entire object is built.

- Support Structures: For complex geometries, support structures are often generated and printed alongside the object to provide support for overhanging sections. These structures are later removed after the printing is complete.

- Cooling and Solidification: As the layers are deposited, they cool and solidify, forming a strong and durable object. The printing process is typically controlled by a computer, which sends instructions to the printer’s nozzle and build platform.

Time Required for Table Production

The time required to print a table with a BigRep 3D printer can vary depending on the size, complexity, and material used. However, printing a large object like a table can take several hours or even days.

For example, a table with dimensions of 1 meter by 1 meter by 0.8 meters could take up to 48 hours to print using a BigRep 3D printer, depending on the printing speed, layer thickness, and material used.

- Printing Speed: The printing speed is a major factor affecting the printing time. Higher printing speeds reduce the time required to complete the print, but can sometimes affect the quality of the print.

- Layer Thickness: The thickness of the layers deposited during printing also affects the printing time. Thicker layers result in faster printing but can reduce the detail and resolution of the object.

- Material Properties: The material used can also affect the printing time. Some materials, such as ABS, have a higher melting point and require longer printing times.

Cost and Feasibility of Table Production: Bigrep 3d Printer Is Huge Enough To Deliver A Whole Table

The cost of producing a table using a BigRep 3D printer is influenced by several factors, including the size and complexity of the design, the materials used, and the printing time. It’s essential to consider these factors to determine the economic viability of 3D printing tables compared to traditional methods.

Material Cost

The cost of materials is a significant factor in 3D printing. BigRep printers can use a variety of materials, including thermoplastics, composites, and even metals. The cost of materials varies depending on the type and quantity used. For example, PLA filament, a common thermoplastic, is relatively inexpensive, while high-performance materials like carbon fiber composites are considerably more expensive.

Printing Time

Printing time is another crucial factor in determining the cost of 3D printing a table. Larger and more complex designs require longer printing times, leading to higher energy consumption and labor costs. The printing time can be estimated based on the volume of the table and the printing speed of the BigRep printer.

Comparison with Traditional Methods

The cost of 3D printing a table can be compared to traditional methods, such as woodworking or metal fabrication. Traditional methods often involve higher upfront costs for tools and equipment, but the cost of materials is generally lower. However, 3D printing offers flexibility in design and customization, potentially reducing labor costs and waste.

Feasibility of Large-Scale Production

The feasibility of using BigRep 3D printers for large-scale table production depends on several factors, including the volume of production, the cost of materials, and the efficiency of the printing process. For high-volume production, the cost of materials and printing time can be a significant barrier. However, the flexibility and customization offered by 3D printing can make it a viable option for niche markets or for producing unique, bespoke furniture.

Examples and Considerations

To illustrate the cost comparison, consider a simple wooden table with a tabletop area of 1 square meter. The cost of materials for a traditional wooden table might be around $50, while the cost of materials for a 3D printed table using PLA filament could be around $100. However, the printing time for the 3D printed table could be significantly longer, potentially adding to the overall cost.

For large-scale production, the cost of materials and printing time becomes even more critical. For example, a company producing 100 tables per month would need to carefully analyze the cost of materials and printing time to determine if 3D printing is economically viable.

It’s important to consider the factors discussed above, including the cost of materials, printing time, and the potential for customization, when evaluating the feasibility of using BigRep 3D printers for table production.

The Future of Large-Scale 3D Printing in Furniture Production

The potential of large-scale 3D printing in furniture production is immense, promising a revolution in design, manufacturing, and sustainability. This technology has the potential to disrupt traditional furniture manufacturing processes, offering a range of benefits that could reshape the industry.

Impact on the Furniture Industry

Large-scale 3D printing is poised to revolutionize the furniture industry by introducing a paradigm shift in design, manufacturing, and customization. Here’s how:

- Design Flexibility: 3D printing allows for complex and intricate designs that are impossible to achieve with traditional manufacturing methods. This opens up a world of possibilities for furniture makers, enabling them to create unique and personalized pieces.

- Mass Customization: With 3D printing, furniture can be customized to individual needs and preferences, allowing consumers to choose from a vast array of designs, materials, and finishes. This personalized approach caters to individual tastes and creates truly unique pieces.

- Reduced Waste: 3D printing is an additive manufacturing process, meaning that only the necessary material is used. This significantly reduces waste compared to traditional subtractive methods, where large amounts of material are discarded during the manufacturing process.

- On-Demand Production: 3D printing allows for on-demand production, eliminating the need for large inventories and reducing lead times. This means that furniture can be produced only when needed, reducing storage costs and minimizing waste.

- Decentralized Manufacturing: 3D printing enables decentralized manufacturing, allowing furniture to be produced closer to consumers. This reduces transportation costs and lead times, making it more efficient and sustainable.

Predictions for Future Development

The future of 3D printing in furniture production is bright, with continuous advancements in technology leading to even more innovative possibilities. Here are some key predictions:

- Increased Material Options: The range of printable materials will expand to include more sustainable and eco-friendly options, such as bio-based plastics, recycled materials, and composite materials.

- Improved Printing Speeds: 3D printing technology will continue to improve, leading to faster printing speeds and higher production volumes.

- Integration of AI and Automation: Artificial intelligence (AI) and automation will play a significant role in the future of 3D printing, optimizing production processes and enhancing design capabilities.

- Enhanced Design Software: 3D design software will become more intuitive and user-friendly, allowing for greater accessibility and ease of use for furniture designers and consumers.

- Growing Market Adoption: As 3D printing technology matures and becomes more accessible, its adoption in the furniture industry is expected to increase significantly.

Innovative Table Design Using 3D Printing Technology

Imagine a table that seamlessly integrates technology, sustainability, and aesthetics. This innovative table design leverages the capabilities of 3D printing to create a unique and functional piece of furniture.

- Sustainable Materials: The table is crafted from recycled plastic, demonstrating a commitment to environmental responsibility. The use of recycled materials reduces waste and promotes sustainability.

- Integrated Lighting: LED lights are embedded within the table’s structure, providing ambient illumination and creating a captivating visual effect. The lights can be controlled through a touch interface, allowing for customizable lighting scenarios.

- Wireless Charging: The table features integrated wireless charging pads, eliminating the need for messy cords and allowing for convenient device charging.

- Customizable Design: The table’s design can be personalized to suit individual preferences. Users can choose from a variety of colors, finishes, and patterns, allowing for a truly unique and bespoke piece of furniture.

Bigrep 3d printer is huge enough to deliver a whole table – The rise of large-scale 3D printing in furniture production is just beginning. As technology advances, we can expect to see even more innovative designs and applications. Imagine a world where you can print your own furniture, customizing every detail to your exact specifications. With BigRep 3D printers, that future is closer than you think.

Imagine a 3D printer so massive it can print a whole table! That’s the kind of power the BigRep 3D printer boasts. While you’re busy printing furniture, you can also use libreoffice online is an open source alternative to office 365 and google docs to design the perfect table for your new 3D printed furniture. With a BigRep 3D printer, the possibilities are truly endless, so get ready to unleash your inner maker!

Standi Techno News

Standi Techno News