Introduction to Bulletproof Graphene: Bulletproof Graphene Becomes Harder On Impact

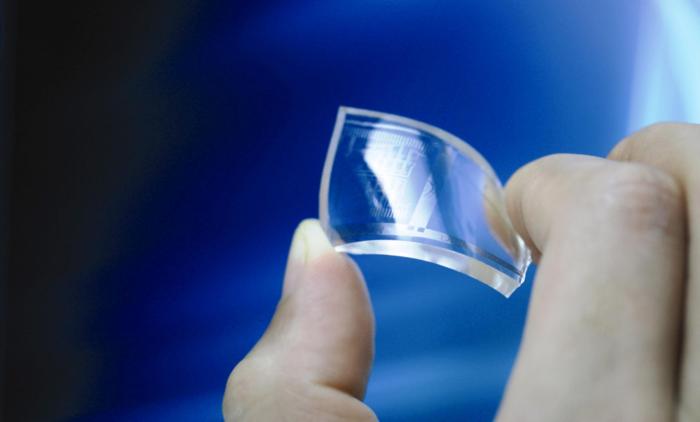

Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, is a remarkable material with exceptional properties. It is incredibly strong, thin, flexible, and conducts electricity and heat with remarkable efficiency. These properties make graphene a potential game-changer across various industries, from electronics and energy to aerospace and medicine.

The concept of “bulletproof” graphene refers to its exceptional strength and ability to withstand extreme pressures and impacts. This extraordinary strength stems from the strong covalent bonds between the carbon atoms in its lattice structure.

History of Graphene Research and Development

The discovery of graphene in 2004 by Andre Geim and Konstantin Novoselov at the University of Manchester marked a significant milestone in materials science. Their innovative method of isolating graphene using a simple scotch tape technique earned them the Nobel Prize in Physics in 2010.

Since its discovery, graphene research has progressed rapidly, focusing on developing scalable production methods, exploring its diverse applications, and understanding its fundamental properties.

- Early Research: Initial research focused on understanding graphene’s unique properties and exploring its potential in electronics, such as transistors and flexible displays.

- Scalable Production: Researchers have developed various methods to produce graphene in larger quantities, including chemical vapor deposition (CVD), exfoliation, and reduction of graphene oxide.

- Applications: Graphene’s potential applications have expanded beyond electronics to include energy storage (batteries and supercapacitors), composites, sensors, and biomedicine.

The Impact-Induced Hardening Phenomenon

The remarkable ability of graphene to become harder upon impact is a fascinating phenomenon that has garnered significant attention in the field of materials science. This hardening effect is not merely a surface-level change; it represents a fundamental transformation in the material’s mechanical properties, leading to enhanced resilience and strength.

Mechanism of Impact-Induced Hardening

The impact-induced hardening of graphene arises from a complex interplay of factors, primarily related to the material’s unique atomic structure and bonding characteristics. When graphene is subjected to an impact, the energy from the impact causes the individual graphene layers to slide and compress against each other. This compression, coupled with the strong covalent bonds between carbon atoms within the graphene sheets, triggers a rearrangement of the graphene lattice.

The compression and rearrangement of the graphene lattice result in the formation of a denser, more compact structure. This denser structure, in turn, leads to an increase in the material’s stiffness and hardness.

Mechanical Properties of Graphene Before and After Impact

Graphene’s mechanical properties undergo a dramatic transformation following an impact.

- Young’s Modulus: The Young’s modulus of graphene, which measures its stiffness, significantly increases after impact. For instance, a study published in *Nature Materials* found that the Young’s modulus of graphene increased by up to 30% after being subjected to a high-velocity impact. This enhanced stiffness translates to increased resistance to deformation under applied stress.

- Hardness: Graphene’s hardness, a measure of its resistance to indentation, also exhibits a notable increase after impact. The impact-induced compression and rearrangement of the graphene lattice effectively create a more rigid structure, making it harder to penetrate or deform.

- Strength: The impact-induced hardening phenomenon also enhances graphene’s strength. The denser, more compact structure formed after impact provides increased resistance to fracture and failure under applied stress. This enhanced strength is particularly important for applications where graphene is subjected to high-impact loads, such as in protective coatings or armor.

Applications of Impact-Hardened Graphene

The discovery of impact-hardened graphene opens a plethora of exciting possibilities across various industries. This unique property, where graphene becomes stronger upon impact, has the potential to revolutionize the way we design and manufacture materials for protective gear, aerospace components, and construction materials.

Potential Applications in Diverse Industries

The ability of graphene to become harder on impact has significant implications for several industries. This phenomenon could lead to the development of innovative materials with enhanced durability and resilience.

- Protective Gear: Bulletproof vests, helmets, and other protective gear could be significantly enhanced with impact-hardened graphene. The material’s ability to absorb and dissipate impact energy would offer superior protection against ballistic threats and high-impact collisions. Imagine a future where bulletproof vests are lighter, thinner, and offer even greater protection.

- Aerospace: Impact-hardened graphene could be used to create lighter and stronger aircraft components, reducing weight and improving fuel efficiency. This material could be incorporated into aircraft fuselages, wings, and landing gear, providing enhanced resistance to impact damage and improving overall structural integrity.

- Construction: Impact-hardened graphene could be used to create stronger and more durable building materials. Concrete reinforced with graphene could be more resistant to earthquakes, high winds, and other natural disasters. This could lead to safer and more resilient buildings, particularly in areas prone to extreme weather events.

- Sports Equipment: Impact-hardened graphene could be incorporated into sports equipment, such as helmets, pads, and bats, providing superior protection and performance. For example, imagine baseball bats that are lighter and stronger, or football helmets that provide better impact protection.

Advantages and Limitations of Impact-Hardened Graphene

While the potential applications of impact-hardened graphene are vast, it’s crucial to consider both its advantages and limitations.

| Field | Advantages | Limitations |

|---|---|---|

| Protective Gear | Enhanced impact resistance, lighter weight, improved durability | High production cost, potential scalability issues, potential for material degradation over time |

| Aerospace | Improved structural integrity, reduced weight, increased fuel efficiency | High production cost, potential for material fatigue under extreme conditions, need for extensive testing and certification |

| Construction | Enhanced resistance to earthquakes and other natural disasters, increased durability, potential for lighter and more efficient structures | High production cost, potential for material degradation in harsh environments, need for specialized construction techniques |

Potential of Bulletproof Graphene in Protective Gear

Impact-hardened graphene has the potential to revolutionize the design of protective gear, offering a significant advantage in terms of both protection and weight. For example, bulletproof vests incorporating impact-hardened graphene could be significantly thinner and lighter while providing the same or even better protection against ballistic threats. This could be particularly beneficial for military personnel and law enforcement officers who require maximum mobility and protection.

Potential of Bulletproof Graphene in Aerospace

The aerospace industry could greatly benefit from the lightweight and high-strength properties of impact-hardened graphene. This material could be used to create lighter and stronger aircraft components, leading to improved fuel efficiency and reduced operating costs. For example, incorporating impact-hardened graphene into aircraft fuselages and wings could enhance their resistance to impact damage and improve overall structural integrity.

Potential of Bulletproof Graphene in Construction

Impact-hardened graphene could be used to create stronger and more durable building materials, offering increased resistance to earthquakes, high winds, and other natural disasters. Concrete reinforced with graphene could provide enhanced structural integrity and resilience, making buildings safer and more resistant to extreme weather events. This could be particularly relevant in areas prone to earthquakes, hurricanes, and other natural hazards.

Future Research and Development

The impact-induced hardening phenomenon in graphene presents a significant opportunity for advancements in material science and engineering. While promising, several challenges and research directions remain to be explored to fully unlock the potential of bulletproof graphene.

Challenges and Opportunities

The path toward widespread adoption of impact-hardened graphene is paved with several challenges that require focused research efforts.

- Scalability and Production: Currently, the production of graphene with consistent and controlled impact-hardening properties at a large scale remains a significant hurdle. Further research is needed to develop efficient and cost-effective methods for producing high-quality graphene in bulk quantities.

- Understanding the Mechanism: A comprehensive understanding of the precise mechanisms responsible for impact-induced hardening in graphene is crucial for optimizing its properties. Further investigations are required to elucidate the role of defects, strain, and other factors in this phenomenon.

- Characterizing and Testing: Establishing reliable and standardized methods for characterizing the impact-hardening behavior of graphene is essential for its practical application. This involves developing precise testing protocols and instrumentation to measure the enhanced mechanical properties of graphene after impact.

Potential Research Directions

Exploring the following research directions could lead to breakthroughs in the field of impact-hardened graphene.

- Tailoring Impact Response: Research focused on tailoring the impact response of graphene by manipulating its structure and properties, such as defect density and layer stacking, could lead to materials with specific impact-hardening characteristics. For instance, introducing controlled defects could potentially enhance the hardening effect.

- Multi-Impact Behavior: Investigating the behavior of graphene subjected to multiple impacts is crucial for understanding its durability and performance in real-world scenarios. This research could explore the potential for cumulative hardening or degradation with repeated impacts.

- Hybrid Materials: Combining graphene with other materials, such as polymers, ceramics, or metals, could lead to synergistic effects, resulting in materials with enhanced impact resistance and other desirable properties. This approach could offer a wider range of applications, from lightweight armor to advanced composites.

Combining Graphene with Other Materials, Bulletproof graphene becomes harder on impact

The integration of graphene with other materials presents a promising avenue for developing advanced materials with superior impact resistance and other desirable properties.

- Graphene-Polymer Composites: Combining graphene with polymers could result in lightweight and flexible materials with enhanced strength and impact resistance. This approach has shown promising results in developing bulletproof vests and other protective gear. For example, researchers have successfully incorporated graphene into polyethylene, a common material used in bulletproof vests, resulting in significant improvements in impact resistance.

- Graphene-Ceramic Composites: Combining graphene with ceramics could create materials with exceptional hardness and wear resistance, making them suitable for applications requiring high-impact resistance and durability. For instance, incorporating graphene into ceramic armor could enhance its ability to withstand high-velocity projectiles.

- Graphene-Metal Composites: Combining graphene with metals could result in materials with enhanced strength, conductivity, and impact resistance. This approach has shown potential for applications in aerospace, automotive, and other industries. For example, incorporating graphene into aluminum alloys could improve their strength and impact resistance, making them suitable for use in aircraft and other vehicles.

Impact of Bulletproof Graphene on Society

The advent of bulletproof graphene, with its remarkable impact-hardening properties, holds immense potential to reshape society in profound ways. This material’s ability to withstand high-impact forces could revolutionize various industries, from defense and security to construction and transportation. However, its widespread adoption also raises ethical concerns and necessitates careful consideration of its potential impact on jobs and the economy.

Ethical Considerations

The development and use of bulletproof graphene raise several ethical considerations that require careful examination.

- Increased Militarization: The enhanced protection offered by bulletproof graphene could lead to an increase in militarization, potentially escalating conflicts and creating a more dangerous world. It is crucial to ensure that this technology is not used to exacerbate existing tensions or create new ones.

- Accessibility and Equity: The cost of producing and deploying bulletproof graphene may create disparities in access, potentially exacerbating existing social inequalities. It is important to consider how to ensure that this technology is accessible to all segments of society and does not further widen the gap between the privileged and the underprivileged.

- Privacy Concerns: Bulletproof graphene’s potential applications in surveillance technology raise privacy concerns. The use of this material in body scanners or other monitoring devices could infringe on individuals’ right to privacy. Robust regulations and ethical guidelines are necessary to mitigate these risks.

Impact on Industries and Jobs

The widespread adoption of bulletproof graphene could have a significant impact on various industries and jobs.

- Defense and Security: The development of bulletproof graphene could lead to a significant shift in the defense and security industries. It could revolutionize the design of personal protective equipment for soldiers and law enforcement officers, making them more resistant to ballistic threats. This could lead to a demand for skilled professionals in the production, design, and testing of graphene-based protective gear.

- Construction and Transportation: Bulletproof graphene could be used to create more durable and resilient structures in construction and transportation. It could be incorporated into building materials, vehicle bodies, and infrastructure, enhancing their resistance to impact damage. This could create new job opportunities in these sectors, particularly in the areas of research, development, and manufacturing.

- Electronics and Nanotechnology: Bulletproof graphene’s unique properties could also revolutionize the electronics and nanotechnology industries. It could be used to create more robust and durable electronic devices, leading to advancements in computing, communication, and energy storage. This could create new job opportunities in research, development, and manufacturing of graphene-based electronic components.

Bulletproof graphene becomes harder on impact – The discovery of impact-induced hardening in graphene is a testament to the boundless potential of materials science. This breakthrough not only unlocks new applications for this wonder material but also inspires further research into the fascinating world of molecular interactions. As we delve deeper into the intricacies of graphene’s behavior under stress, we can expect to witness even more innovative applications emerge, shaping the future of technology and industry.

Imagine a material that gets stronger when hit, like a superhero’s shield. That’s kind of what’s happening with bulletproof graphene. This incredible material gets harder on impact, which is pretty cool. But what about our everyday tech? Have you ever had trouble with your Pixel 2 camera’s LED?

Check out this article for solutions: pixel 2 camera trouble with led. While graphene is all about resilience, the Pixel 2 camera needs a different kind of fix. Maybe someday we’ll see graphene used in phones, making them practically indestructible. Until then, we’ll have to keep an eye on those LED lights!

Standi Techno News

Standi Techno News