Coast Runner CNC CES isn’t just another acronym in the world of manufacturing; it’s a revolution in precision engineering. Imagine a world where complex designs come to life with unparalleled accuracy and efficiency. That’s the promise of Coast Runner CNC CES, a technology that’s transforming industries from aerospace to automotive and beyond.

Coast Runner CNC CES utilizes advanced computer numerical control (CNC) systems to guide cutting-edge machinery, allowing for intricate designs and highly detailed creations. This isn’t your grandpa’s machine shop – think of it as a symphony of technology, where every movement is precise and every detail is meticulously controlled.

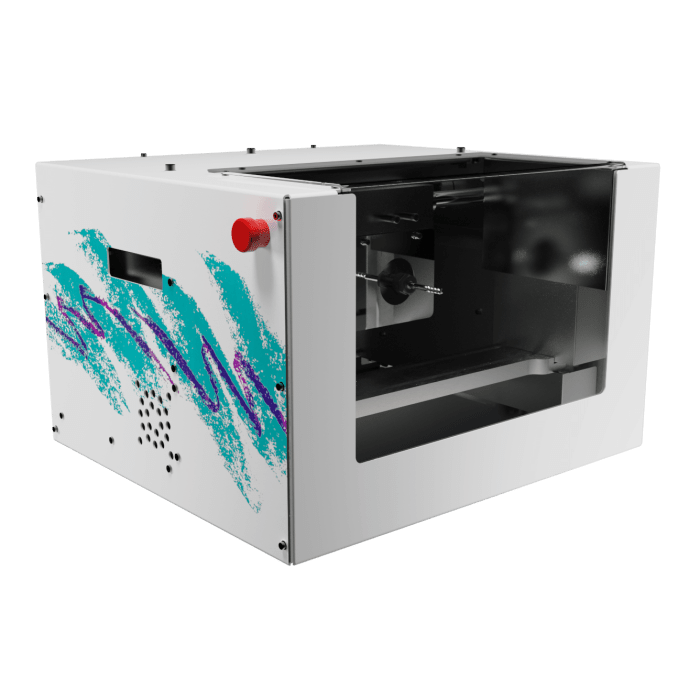

Coast Runner CNC CES

Coast Runner CNC CES (Computerized Embroidery System) is a comprehensive system that combines advanced CNC technology with embroidery capabilities, offering a seamless solution for various applications in the textile and apparel industries.

The primary function of Coast Runner CNC CES is to automate the embroidery process, allowing for precise and intricate designs to be created on a wide range of fabrics. It uses computer-controlled machinery to guide needles and threads, ensuring high-quality and consistent results. This technology streamlines production, increases efficiency, and minimizes human error.

Coast Runner CNC CES, a leading provider of high-precision CNC machining services, has been making waves in the industry. While they’re busy innovating, it seems like things are getting a bit chaotic over at X, with Don Lemon saying Elon Musk has canceled his show. Perhaps Coast Runner CNC CES can offer some stability and precision to the world of social media, one expertly crafted part at a time.

Applications of Coast Runner CNC CES

Coast Runner CNC CES finds application in a variety of industries, including:

- Apparel manufacturing: Producing high-quality embroidered garments, logos, and designs for various brands and retailers.

- Textile manufacturing: Creating intricate patterns and designs on fabrics for home furnishings, upholstery, and other applications.

- Promotional products: Embroidering logos, designs, and personalized messages on caps, bags, and other promotional items.

- Art and craft: Providing a precise and versatile tool for creating custom embroidery projects for artists and hobbyists.

Target Audience

Coast Runner CNC CES caters to a diverse target audience, including:

- Apparel manufacturers and designers: Looking to enhance their production efficiency and create high-quality embroidered garments.

- Textile manufacturers and suppliers: Seeking to automate and improve the embroidery process for various fabric applications.

- Promotional product companies: Offering personalized and customized embroidery services to clients.

- Artists and crafters: Exploring advanced embroidery techniques and creating unique custom projects.

Coast Runner CNC CES Technology

Coast Runner CNC CES products utilize a range of advanced technologies to deliver high-precision, automated cutting and engraving solutions. These technologies are carefully chosen and integrated to optimize performance, accuracy, and reliability.

Key Technologies Employed

The core technologies employed in Coast Runner CNC CES products include:

- Computer Numerical Control (CNC) Technology: This technology forms the foundation of Coast Runner CNC CES systems. CNC technology utilizes computer programs to control the movement of cutting tools, ensuring precise and repeatable cuts. This allows for complex designs and intricate details to be realized with high accuracy.

- Linear Rail Systems: Coast Runner CNC CES systems typically employ linear rail systems for smooth and precise movement of the cutting head. These systems consist of linear bearings that ride on hardened steel rails, minimizing friction and maximizing accuracy. They are known for their high load capacity and long service life, making them suitable for demanding applications.

- High-Torque Motors: Powerful and precise high-torque motors drive the movement of the cutting head in Coast Runner CNC CES systems. These motors provide the necessary force to achieve high cutting speeds and ensure smooth and consistent operation, even when cutting through dense materials.

- Advanced Control Software: Coast Runner CNC CES systems are typically equipped with user-friendly software that allows for easy control and programming. These software packages offer features like automatic tool path generation, simulation capabilities, and real-time monitoring, simplifying the design and production process.

- Laser Cutting Technology: In some Coast Runner CNC CES systems, laser cutting technology is integrated. Laser cutting uses a focused beam of light to cut materials with high precision and minimal heat-affected zones. This technology is particularly well-suited for intricate designs and delicate materials.

- Plasma Cutting Technology: Coast Runner CNC CES systems may also incorporate plasma cutting technology. This method uses a high-temperature plasma arc to cut materials, offering high cutting speeds and the ability to handle thick materials. Plasma cutting is often used for industrial applications requiring rapid and efficient material removal.

Advantages of Coast Runner CNC CES Technology

The technologies employed in Coast Runner CNC CES products offer several advantages:

- High Accuracy and Precision: CNC technology, combined with linear rail systems and precise motor control, enables Coast Runner CNC CES systems to achieve high levels of accuracy and precision in cutting and engraving operations. This is crucial for producing high-quality components and intricate designs.

- Repeatability and Consistency: The automated nature of CNC technology ensures high repeatability and consistency in the cutting process. This is vital for manufacturing applications where maintaining consistent quality is essential.

- Flexibility and Versatility: Coast Runner CNC CES systems are highly flexible and versatile. They can handle a wide range of materials, from plastics and wood to metals and composites. This allows for diverse applications in various industries.

- Increased Productivity and Efficiency: Automation through CNC technology significantly increases productivity and efficiency compared to manual cutting methods. Coast Runner CNC CES systems can operate continuously and with minimal human intervention, leading to faster production times and lower labor costs.

- Enhanced Safety: Coast Runner CNC CES systems are designed with safety features that minimize the risk of operator injury. The automated nature of the cutting process eliminates the need for manual handling of sharp tools, reducing the potential for accidents.

Limitations of Coast Runner CNC CES Technology

While Coast Runner CNC CES technology offers significant advantages, it also has some limitations:

- Initial Investment Cost: Coast Runner CNC CES systems can be expensive to purchase and install, making them a significant investment for businesses. The cost of the system, software, and training can be a barrier for smaller businesses.

- Maintenance and Repair Costs: CNC systems require regular maintenance and may incur repair costs if components fail. The cost of maintenance and repairs can be significant over the lifetime of the system.

- Complexity of Programming: Programming CNC systems can be complex, requiring specialized skills and knowledge. It may take time and effort to learn the software and develop effective programs.

- Limited Material Thickness: Some CNC systems have limitations in the thickness of materials they can cut. This can be a constraint for applications requiring the processing of thick materials.

Comparison to Alternative Solutions

Coast Runner CNC CES technology offers several advantages over alternative solutions, such as manual cutting, waterjet cutting, and laser cutting:

- Manual Cutting: Coast Runner CNC CES systems offer significantly higher accuracy, repeatability, and efficiency compared to manual cutting methods. They also reduce the risk of operator injury and fatigue.

- Waterjet Cutting: Waterjet cutting is another high-precision cutting method, but it can be more expensive and less versatile than Coast Runner CNC CES systems. Waterjet cutting is often used for thicker materials and more complex shapes.

- Laser Cutting: Laser cutting offers high precision and minimal heat-affected zones, making it suitable for delicate materials. However, laser cutting can be more expensive than Coast Runner CNC CES systems and may have limitations in the thickness of materials it can cut.

Coast Runner CNC CES Features and Capabilities

Coast Runner CNC CES systems are designed to provide exceptional precision, efficiency, and versatility for a wide range of applications. They boast a unique blend of advanced features and capabilities, catering to the needs of both novice and experienced users.

Key Features of Coast Runner CNC CES Systems

Coast Runner CNC CES systems are equipped with a range of core features that enhance their performance and usability. These features contribute to the overall efficiency and accuracy of the systems, making them suitable for various applications.

- High-Precision Linear Rails: Coast Runner CNC CES systems utilize high-precision linear rails, ensuring smooth and accurate movement along the X, Y, and Z axes. These rails minimize friction and wear, contributing to the system’s long-term performance and accuracy.

- Advanced Control System: The systems are equipped with a sophisticated control system that enables precise control over movement, speed, and acceleration. This control system allows for intricate and complex designs to be executed with accuracy.

- User-Friendly Interface: Coast Runner CNC CES systems are designed with a user-friendly interface, simplifying operation and making them accessible to users with varying levels of experience. The intuitive interface minimizes the learning curve and allows users to quickly become proficient in operating the system.

- Modular Design: The modular design of Coast Runner CNC CES systems allows for easy customization and expansion. Users can choose from a variety of components and accessories to tailor the system to their specific needs and applications.

Capabilities and Functionalities of Coast Runner CNC CES Systems

Coast Runner CNC CES systems are capable of performing a wide range of tasks, making them valuable tools in various industries. The systems are designed to handle complex designs and intricate details, providing high-quality results.

- Precise Cutting and Engraving: Coast Runner CNC CES systems are highly effective for precise cutting and engraving of various materials, including wood, metal, plastic, and composites. The systems’ accuracy and control allow for intricate designs and detailed patterns to be executed flawlessly.

- 3D Modeling and Prototyping: Coast Runner CNC CES systems can be used for 3D modeling and prototyping, allowing users to create physical representations of their designs. This capability is essential for product development, design validation, and testing.

- Automated Manufacturing: Coast Runner CNC CES systems can be integrated into automated manufacturing processes, increasing efficiency and productivity. The systems can perform repetitive tasks with accuracy and consistency, reducing the need for manual intervention.

- Customizable Applications: Coast Runner CNC CES systems can be customized for a wide range of applications, including signage, jewelry making, furniture design, and industrial production. Their versatility allows them to be adapted to meet the specific requirements of various industries.

Features, Benefits, and Applications

The following table summarizes key features of Coast Runner CNC CES systems, their associated benefits, and potential applications:

| Feature | Benefit | Applications |

|---|---|---|

| High-Precision Linear Rails | Precise and smooth movement, reduced friction and wear | Precise cutting and engraving, 3D modeling, automated manufacturing |

| Advanced Control System | Accurate control over movement, speed, and acceleration | Intricate designs, complex patterns, high-quality results |

| User-Friendly Interface | Easy operation, accessible to users of all levels | Educational institutions, hobbyists, professional workshops |

| Modular Design | Customization and expansion, tailored to specific needs | Various industries, diverse applications, individual preferences |

Coast Runner CNC CES in Action

Coast Runner CNC CES isn’t just a theoretical concept; it’s a powerful tool that’s already being implemented in a wide range of industries and projects, driving real-world improvements and transforming how businesses operate.

This section delves into the practical applications of Coast Runner CNC CES, showcasing real-world examples and case studies that highlight its tangible benefits. We’ll explore how Coast Runner CNC CES is impacting specific industries and projects, demonstrating its transformative power in action.

Coast Runner CNC CES in Manufacturing

The manufacturing industry is a prime example of how Coast Runner CNC CES can be leveraged to optimize processes and enhance productivity. Coast Runner CNC CES enables manufacturers to achieve greater efficiency and accuracy in their production lines, leading to higher quality products and reduced waste.

- Automotive Manufacturing: Coast Runner CNC CES is being used by automotive manufacturers to automate complex assembly processes, such as the production of car doors, engine components, and chassis. By implementing Coast Runner CNC CES, manufacturers can significantly reduce the time and labor required for these processes, while also achieving greater consistency and accuracy in their final products.

- Aerospace Manufacturing: The aerospace industry relies heavily on precision and accuracy. Coast Runner CNC CES is being used to create intricate components for aircraft, such as wings, fuselages, and engine parts. The high level of precision and automation offered by Coast Runner CNC CES allows aerospace manufacturers to meet the demanding requirements of this industry.

- Consumer Electronics: The production of consumer electronics involves intricate and delicate components. Coast Runner CNC CES is used to automate the assembly of smartphones, laptops, and other electronic devices. By using Coast Runner CNC CES, manufacturers can ensure the consistency and quality of these products, while also reducing production costs.

Coast Runner CNC CES in Healthcare

The healthcare industry is also benefiting from the implementation of Coast Runner CNC CES. This technology is being used to create custom prosthetics, medical implants, and surgical instruments, leading to improved patient outcomes and reduced healthcare costs.

- Prosthetics and Orthotics: Coast Runner CNC CES is being used to create personalized prosthetics and orthotics, tailored to the specific needs of each patient. This technology allows for greater accuracy and precision in the creation of these devices, leading to improved comfort, functionality, and mobility for patients.

- Surgical Instruments: Coast Runner CNC CES is being used to create surgical instruments with complex designs and high levels of precision. This allows surgeons to perform minimally invasive procedures with greater accuracy and control, leading to faster recovery times and reduced complications for patients.

- Medical Implants: Coast Runner CNC CES is being used to create custom medical implants, such as hip and knee replacements, that are tailored to the individual anatomy of each patient. This allows for a more precise fit and improved functionality, leading to better patient outcomes and a longer lifespan for the implants.

Coast Runner CNC CES in Construction

The construction industry is undergoing a digital transformation, and Coast Runner CNC CES is playing a key role in this evolution. Coast Runner CNC CES is being used to create prefabricated components, such as walls, floors, and roofs, leading to faster construction times and reduced costs.

- Prefabricated Components: Coast Runner CNC CES is being used to create prefabricated components for buildings, such as walls, floors, and roofs. These components can be manufactured off-site and then assembled on-site, leading to faster construction times and reduced labor costs.

- Architectural Design: Coast Runner CNC CES is being used to create complex architectural designs, such as curved walls and intricate facades. This technology allows architects to push the boundaries of design and create unique and innovative structures.

- Infrastructure Projects: Coast Runner CNC CES is being used in large-scale infrastructure projects, such as bridges, tunnels, and dams. This technology allows for the creation of complex and precise structures that can withstand the rigors of the environment.

Coast Runner CNC CES in Education

Coast Runner CNC CES is also being used in educational institutions to teach students about manufacturing, design, and engineering. By providing students with hands-on experience with Coast Runner CNC CES, educators can inspire the next generation of innovators and entrepreneurs.

- STEM Education: Coast Runner CNC CES is being used in STEM education programs to teach students about design, engineering, and manufacturing. By providing students with hands-on experience with Coast Runner CNC CES, educators can inspire the next generation of innovators and entrepreneurs.

- Technical Training: Coast Runner CNC CES is being used to provide technical training for professionals in various industries. This technology allows workers to learn new skills and become more proficient in their fields, leading to increased productivity and innovation.

- Maker Spaces: Coast Runner CNC CES is being used in maker spaces to provide individuals with access to advanced manufacturing tools and technologies. This allows people to pursue their creative passions and develop innovative products.

The Future of Coast Runner CNC CES

The Coast Runner CNC CES market is poised for significant growth and innovation, driven by technological advancements, evolving industry trends, and increasing demand for precision and efficiency in manufacturing. The future of Coast Runner CNC CES holds immense potential, with advancements in automation, connectivity, and sustainability expected to revolutionize the industry.

Emerging Trends and their Impact on the Coast Runner CNC CES Market

The Coast Runner CNC CES market is being shaped by a number of emerging trends that are driving innovation and growth. These trends include:

- Increased Adoption of Automation: Automation is becoming increasingly prevalent in manufacturing, as companies seek to improve efficiency, reduce costs, and enhance productivity. Coast Runner CNC CES is well-positioned to benefit from this trend, as its automated systems can significantly reduce manual labor requirements and improve accuracy.

- Growing Demand for Customization and Mass Personalization: Consumers are increasingly demanding customized products, leading to a shift towards mass personalization. Coast Runner CNC CES can play a crucial role in this trend by enabling manufacturers to produce highly customized products on demand.

- Advancements in Artificial Intelligence (AI) and Machine Learning (ML): AI and ML are transforming various industries, including manufacturing. Coast Runner CNC CES can leverage these technologies to optimize production processes, improve quality control, and enhance predictive maintenance capabilities.

- Focus on Sustainability and Environmental Responsibility: Sustainability is becoming increasingly important for businesses. Coast Runner CNC CES can contribute to a more sustainable manufacturing industry by reducing waste, optimizing energy consumption, and promoting the use of eco-friendly materials.

Potential Milestones and Innovations in Coast Runner CNC CES

The future of Coast Runner CNC CES is likely to be marked by a number of significant milestones and innovations. These include:

- Development of Advanced Robotics and Collaborative Robots (Cobots): The integration of advanced robotics and cobots will further enhance automation capabilities, enabling more complex and precise tasks.

- Integration of Cloud Computing and Edge Computing: Cloud and edge computing will enable real-time data analysis, remote monitoring, and improved connectivity, facilitating seamless integration and optimization of Coast Runner CNC CES systems.

- Advancements in Additive Manufacturing (3D Printing): Additive manufacturing will play a growing role in the Coast Runner CNC CES market, enabling the production of complex and customized parts with greater flexibility and efficiency.

- Development of Smart Manufacturing Systems: Coast Runner CNC CES will become increasingly integrated with smart manufacturing systems, enabling real-time data collection, analysis, and decision-making, leading to greater efficiency and productivity.

Coast Runner CNC CES isn’t just about building things; it’s about pushing the boundaries of what’s possible. From crafting intricate components for spacecraft to creating personalized medical devices, this technology is unlocking a world of possibilities. As we continue to explore the potential of Coast Runner CNC CES, we can expect even more innovations that will shape the future of manufacturing and beyond.

Standi Techno News

Standi Techno News