The Concept of Digital Clone Machines: Digital Clone Machines Lifespan

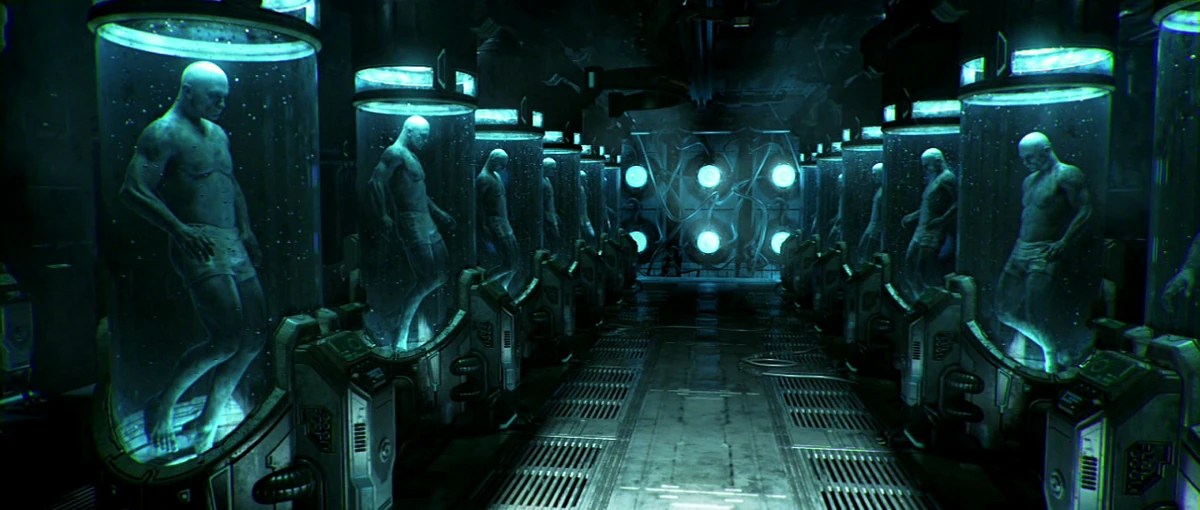

Imagine a machine that could create a perfect digital replica of a person, capturing their thoughts, memories, and personality. This is the essence of a digital clone machine, a hypothetical device that aims to replicate the essence of a human being in a digital form.

While still in the realm of science fiction, the concept of digital clone machines raises fascinating questions about consciousness, identity, and the future of human interaction.

Potential Applications of Digital Clone Machines

The potential applications of digital clone machines span various industries, from entertainment to healthcare.

- Entertainment: Digital clone machines could revolutionize the entertainment industry by creating realistic digital actors for movies, video games, and virtual reality experiences. Imagine interacting with a digital clone of your favorite celebrity or historical figure in a virtual world.

- Healthcare: Digital clones could assist in medical diagnosis and treatment by providing personalized medical advice based on an individual’s unique genetic makeup and medical history.

- Education: Digital clone machines could create personalized learning experiences by tailoring educational content to each student’s individual needs and learning style.

- Business: Digital clones could be used for customer service, sales, and marketing, providing personalized interactions and answering questions in real-time.

Examples of Digital Clone Machines

While the concept of a fully functional digital clone machine remains hypothetical, there are existing technologies that offer glimpses into the potential capabilities of such a device.

- Chatbots: Chatbots are AI-powered programs that can engage in conversations with humans. While they don’t replicate a person’s entire consciousness, they demonstrate the potential for creating digital entities that can interact with humans in a meaningful way.

- Deepfakes: Deepfakes are synthetic media that use artificial intelligence to create realistic-looking videos of people saying or doing things they never actually did. While deepfakes are often used for malicious purposes, they highlight the growing ability to create realistic digital representations of people.

- Virtual Assistants: Virtual assistants like Siri, Alexa, and Google Assistant are AI-powered programs that can respond to voice commands and provide information. While they don’t have a physical body or a full understanding of the world, they demonstrate the potential for creating digital entities that can interact with humans in a natural and intuitive way.

Factors Influencing Lifespan

The lifespan of a digital clone machine is influenced by a complex interplay of factors, including the quality of its components, the effectiveness of software updates and maintenance, and the pace of technological advancements. Understanding these factors is crucial for predicting the longevity of these machines and making informed decisions about their deployment and maintenance.

Software Updates and Maintenance

Software updates play a critical role in extending the lifespan of digital clone machines. Regular updates provide essential security patches, bug fixes, and performance enhancements, ensuring the machine operates smoothly and remains secure against vulnerabilities. Timely updates minimize the risk of system failures, data breaches, and other security threats, contributing to the overall longevity of the machine.

Regular software updates are essential for maintaining the security and stability of digital clone machines.

- Security Patches: Updates often include security patches that address vulnerabilities discovered in the machine’s software, preventing malicious actors from exploiting weaknesses and compromising the system. For instance, in 2017, the WannaCry ransomware attack exploited a vulnerability in Microsoft Windows, highlighting the importance of regular updates in protecting against such threats.

- Bug Fixes: Updates frequently contain bug fixes that address software errors or glitches, improving the stability and performance of the machine. By eliminating bugs, updates ensure that the machine operates smoothly and reliably, minimizing the risk of system crashes or unexpected behavior.

- Performance Enhancements: Updates can also include performance enhancements, such as optimizations for specific tasks or improvements to resource management. These enhancements can lead to faster processing speeds, reduced resource consumption, and overall better performance, extending the useful lifespan of the machine.

In addition to software updates, regular maintenance is crucial for maintaining the longevity of digital clone machines. This includes tasks such as cleaning the system, optimizing storage space, and running diagnostics to identify and address potential issues before they escalate.

Regular maintenance helps prevent minor issues from becoming major problems, ensuring the long-term health and stability of the machine.

Technological Advancements and Lifespan

The lifespan of digital clone machines is inextricably linked to the pace of technological advancements, particularly in computing power and storage capacity. As these areas progress, so too does the potential for creating more sophisticated and enduring digital clones.

Computing Power and Storage Capacity

The computational demands of creating and maintaining a digital clone are substantial. These demands are directly related to the complexity of the individual being cloned, the level of detail desired in the clone, and the duration of its lifespan. Higher computing power allows for more intricate simulations, leading to more realistic and detailed clones. Similarly, greater storage capacity is required to hold the vast amounts of data that represent the clone’s personality, memories, and experiences.

The lifespan of a digital clone is fundamentally limited by the capacity of the hardware and software that sustains it.

As computing power and storage capacity increase, the lifespan of digital clones is expected to extend. This is because more complex simulations can be sustained for longer periods, and the data representing the clone can be stored and accessed more efficiently.

Environmental Factors and Lifespan

The environment surrounding a digital clone machine plays a crucial role in determining its lifespan. Factors like temperature, humidity, and power fluctuations can significantly impact the machine’s performance and longevity. Maintaining a controlled environment is essential for ensuring the machine’s optimal operation and extending its lifespan.

Temperature and Humidity, Digital clone machines lifespan

Temperature and humidity levels can directly affect the performance and lifespan of a digital clone machine.

- High temperatures can lead to overheating, which can damage components and reduce their lifespan.

- Excessive humidity can cause condensation, which can lead to corrosion and short circuits.

- Low humidity can cause static electricity buildup, which can damage sensitive components.

It is crucial to maintain a stable temperature and humidity level within the recommended operating range specified by the manufacturer.

Ventilation and Cooling Systems

Proper ventilation and cooling systems are essential for maintaining a stable operating temperature and preventing overheating.

- Adequate ventilation ensures proper airflow, dissipating heat generated by the machine.

- Cooling systems, such as fans and heat sinks, help to remove excess heat and maintain optimal operating temperatures.

Regular maintenance of ventilation and cooling systems is vital for ensuring their effectiveness and preventing overheating issues.

Dust, Debris, and Contaminants

Dust, debris, and other environmental contaminants can accumulate on the machine’s components, obstructing airflow and causing malfunctions.

- Dust buildup can clog ventilation openings, reducing airflow and increasing operating temperatures.

- Debris can accumulate on sensitive components, causing short circuits and malfunctions.

- Contaminants can corrode components, reducing their lifespan and performance.

Regular cleaning and maintenance are essential for removing dust, debris, and contaminants, ensuring optimal performance and extending the machine’s lifespan.

Operational Practices and Lifespan

The lifespan of a digital clone machine is not solely determined by its internal components; operational practices play a crucial role in ensuring its longevity and optimal performance. Adopting best practices and implementing regular maintenance can significantly extend the operational life of these machines, maximizing their utility and minimizing downtime.

Regular Maintenance and Preventative Measures

Regular maintenance is essential for maintaining the health and longevity of digital clone machines. It involves a series of proactive steps designed to identify and address potential issues before they escalate into major problems. These preventative measures can significantly reduce the risk of unexpected failures, costly repairs, and downtime.

- Regular Cleaning: Dust, debris, and other contaminants can accumulate within the machine, hindering airflow and leading to overheating. Regular cleaning, including vacuuming and compressed air, helps maintain optimal airflow and prevents component damage.

- Component Inspection: Regularly inspecting critical components, such as fans, power supplies, and cooling systems, allows for early detection of wear and tear. Replacing worn or damaged components proactively prevents catastrophic failures and extends the machine’s lifespan.

- Software Updates: Software updates often include bug fixes, security patches, and performance enhancements. Regularly updating the machine’s software ensures optimal performance and minimizes the risk of vulnerabilities that could compromise its operation.

- Monitoring System Health: Monitoring the machine’s temperature, power consumption, and other vital parameters provides early warning signs of potential issues. This allows for timely intervention and prevents minor problems from escalating into major failures.

Impact of Usage Patterns and Workload

The usage patterns and workload placed on a digital clone machine can significantly impact its lifespan. High-intensity workloads and prolonged periods of operation can accelerate wear and tear on components, potentially leading to premature failure. Understanding the relationship between usage patterns and lifespan is crucial for optimizing machine operation and extending its service life.

- Workload Optimization: Distributing the workload evenly across multiple machines can reduce the strain on individual units. This approach helps to prevent premature wear and tear and extends the overall lifespan of the machine fleet.

- Scheduled Downtime: Regularly scheduling downtime for maintenance and repairs allows for proactive component replacement and system optimization. This approach minimizes the risk of unexpected failures and ensures that the machines remain operational for extended periods.

- Cooling System Management: Maintaining optimal cooling conditions is essential for preventing overheating and component damage. Ensuring proper airflow and ventilation, and monitoring system temperatures, are crucial for maintaining the machine’s health and extending its lifespan.

Sustainability and End-of-Life Considerations

Digital clone machines, despite their potential benefits, come with environmental considerations that need careful attention. The lifecycle of these machines, from manufacturing to disposal, has a significant impact on the environment. This section examines the environmental impact of digital clone machines, explores responsible disposal and recycling practices, and delves into strategies for extending their lifespan.

Environmental Impact of Digital Clone Machines

The environmental impact of digital clone machines can be analyzed throughout their lifecycle, encompassing manufacturing, operation, and disposal.

- Manufacturing: The production of digital clone machines requires substantial energy and resources. Mining and processing of raw materials like metals, plastics, and rare earth elements contribute to greenhouse gas emissions, deforestation, and pollution.

- Operation: During operation, digital clone machines consume electricity, generating greenhouse gas emissions. The energy consumption of these machines depends on their size, complexity, and usage patterns. The cooling systems required to prevent overheating also contribute to energy consumption and potential emissions.

- Disposal: The disposal of end-of-life digital clone machines poses a significant challenge. Improper disposal can lead to the release of hazardous materials into the environment, contaminating soil and water resources. Electronic waste (e-waste) is a growing global problem, requiring careful management to minimize its environmental impact.

Responsible Disposal and Recycling Practices

Proper disposal and recycling of digital clone machines are crucial for mitigating their environmental impact.

- E-Waste Collection and Management: Establishing efficient e-waste collection systems is essential for ensuring that end-of-life machines are properly disposed of. This involves partnering with certified e-waste recyclers who have the expertise and infrastructure to safely dismantle and recycle components.

- Material Recovery and Recycling: Digital clone machines contain valuable materials that can be recovered and recycled. Metals, plastics, and other components can be extracted and reused, reducing the demand for virgin materials and minimizing waste.

- Extended Producer Responsibility (EPR): Implementing EPR programs holds manufacturers responsible for the environmental impact of their products throughout their lifecycle, including end-of-life management. This encourages manufacturers to design products for easy disassembly and recycling, as well as to take responsibility for their disposal.

Strategies for Extending Lifespan

Extending the lifespan of digital clone machines is a key strategy for reducing their environmental impact.

- Software Upgrades: Regular software updates can enhance performance, improve compatibility, and extend the functional lifespan of digital clone machines. Software upgrades can address obsolescence issues and keep machines running smoothly for longer periods.

- Hardware Upgrades: Replacing or upgrading key hardware components, such as memory, storage, or processors, can extend the operational life of digital clone machines. This can be a cost-effective alternative to replacing the entire machine.

- Repurposing: End-of-life digital clone machines can be repurposed for other applications. Components can be salvaged and used in other devices, or the machines themselves can be donated to educational institutions or charitable organizations.

Digital clone machines lifespan – From the intricate interplay of hardware and software to the impact of environmental factors and operational practices, understanding the lifespan of digital clone machines is crucial for their effective deployment. As technology continues to evolve, we can expect to see even more innovative approaches to extending their lifespan, further enhancing their impact on our lives. So, the next time you encounter a digital clone machine, remember the fascinating story behind its creation and the intricate factors that contribute to its longevity.

The lifespan of digital clone machines is a hot topic these days, especially as the technology continues to evolve. We’re talking about the ability to recreate ourselves in the digital realm, with all our memories and experiences. While this might sound like something out of a sci-fi movie, it’s actually getting closer to reality. Take the upcoming DLC for Mario Kart 8, for example, which will introduce a 200cc racing mode.

mario kart 8 to get 200cc racing mode in upcoming dlc This new mode will allow players to experience the game at a whole new level of speed, just like digital clones might experience the world in a whole new way. So, while we might be a long way from creating perfect digital clones, the future is definitely exciting!

Standi Techno News

Standi Techno News