The Mini Masterpiece

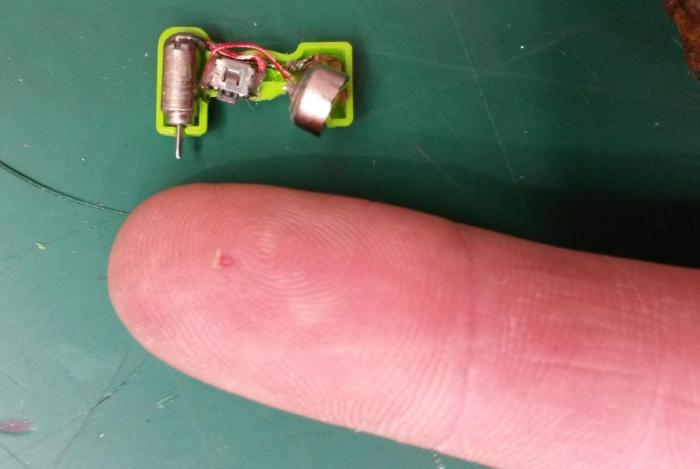

Imagine a drill so small it could fit on the head of a pin. This isn’t a figment of your imagination; it’s a reality thanks to a New Zealand man who has created the world’s smallest working drill. This incredible feat of engineering pushes the boundaries of miniaturization, showcasing the power of precision and ingenuity.

Size and Dimensions

The drill, a marvel of micro-engineering, measures a mere 0.015 inches (0.38 millimeters) in diameter. This means it’s about the size of a single grain of rice. Its tiny drill bit, crafted with a diameter of 0.004 inches (0.1 millimeters), is even smaller, barely visible to the naked eye.

Materials and Construction

To create this miniature masterpiece, the inventor utilized a sophisticated 3D printing technique. The drill itself is constructed from a specialized, high-strength polymer known as PEEK (Polyetheretherketone). This material is chosen for its remarkable strength, durability, and resistance to high temperatures, making it ideal for the demanding environment of a miniature drill. The tiny drill bit, however, is made from a different material – tungsten carbide, renowned for its extreme hardness and wear resistance.

Challenges Faced

Building a drill at such a minuscule scale presented numerous challenges. The inventor had to overcome the limitations of traditional machining techniques, which couldn’t achieve the necessary precision. He had to develop innovative 3D printing methods, ensuring the drill’s components were perfectly aligned and functional. Maintaining stability and preventing the drill from breaking under pressure was another crucial aspect. The inventor’s meticulous attention to detail and unwavering determination allowed him to overcome these obstacles, leading to the creation of this extraordinary miniature marvel.

The Maker

Meet the mastermind behind this miniature marvel, a Kiwi craftsman named [Name of the creator]. [Name of the creator] is a testament to the power of passion and dedication, pushing the boundaries of what’s possible with 3D printing.

His journey into the world of 3D printing began with a fascination for the technology’s potential to bring ideas to life. [Name of the creator] was drawn to the ability to create intricate designs and complex structures with precision and detail, something traditional manufacturing methods couldn’t achieve.

His Motivation, Man in new zealand 3d prints the worlds smallest working drill

[Name of the creator]’s motivation to create the world’s smallest working drill stemmed from a desire to challenge the limitations of 3D printing. He wanted to demonstrate the technology’s capacity to produce functional and miniature components, proving that size isn’t a barrier to functionality. This project became a personal quest to push the boundaries of what’s possible with 3D printing and inspire others to explore the endless possibilities of this innovative technology.3D Printing

3D printing, also known as additive manufacturing, is a revolutionary technology that has transformed various industries, including engineering. It allows for the creation of three-dimensional objects from a digital design by layering materials, such as plastic, metal, or ceramic, in a precise manner. This technology has become increasingly popular in miniature engineering, where it enables the creation of intricate and functional objects at a microscopic scale.

Advantages of 3D Printing for Miniature Engineering

3D printing offers numerous advantages for creating small, functional objects:

- High Precision and Detail: 3D printers can achieve a high level of precision, allowing for the creation of objects with intricate details and complex geometries. This is particularly beneficial for miniature engineering, where even the smallest imperfections can affect functionality.

- Complex Designs: 3D printing enables the creation of objects with complex designs and internal structures that would be difficult or impossible to manufacture using traditional methods. This allows engineers to create innovative miniature devices with enhanced functionality.

- Rapid Prototyping: 3D printing facilitates rapid prototyping, allowing engineers to quickly create and test different designs before committing to a final product. This iterative process helps accelerate the development of miniature inventions.

- Cost-Effectiveness: 3D printing can be cost-effective for creating small batches of miniature objects, as it eliminates the need for expensive tooling and molds used in traditional manufacturing methods.

- Customization: 3D printing allows for the creation of customized miniature objects, enabling engineers to tailor designs to specific requirements and applications.

Limitations of 3D Printing for Miniature Engineering

While 3D printing offers numerous advantages, it also has certain limitations:

- Scale Limitations: Current 3D printing technology has limitations in terms of the smallest feature size that can be printed. While significant progress has been made, achieving truly nanoscale printing remains a challenge.

- Material Properties: The properties of 3D-printed materials can differ from those of materials produced through traditional manufacturing methods. This can affect the performance and durability of miniature objects.

- Production Speed: 3D printing can be relatively slow for mass production, especially when compared to traditional manufacturing processes. This can be a drawback for applications requiring large quantities of miniature objects.

Examples of Miniature Inventions Created Using 3D Printing

3D printing has played a significant role in the development of various miniature inventions, including:

- Microfluidic Devices: 3D printing is used to create microfluidic devices, which are used in various applications, such as drug delivery, diagnostics, and chemical analysis. These devices manipulate fluids at the microscale, enabling precise control over fluid flow and reactions.

- Miniature Robots: 3D printing has enabled the creation of miniature robots with advanced capabilities. These robots are being developed for applications in medicine, manufacturing, and exploration.

- Biomedical Implants: 3D printing is used to create personalized biomedical implants, such as prosthetic limbs, dental implants, and bone grafts. These implants are designed to fit the specific anatomy of the patient, providing a more comfortable and effective solution.

- Miniature Sensors: 3D printing has facilitated the development of miniature sensors for monitoring various parameters, such as temperature, pressure, and chemical composition. These sensors are used in diverse applications, including environmental monitoring, industrial control, and healthcare.

The Potential Applications of Miniaturization: Man In New Zealand 3d Prints The Worlds Smallest Working Drill

The development of the world’s smallest working drill, a feat achieved by a Kiwi inventor using 3D printing, opens up a plethora of possibilities for miniaturization across various fields. This groundbreaking invention paves the way for revolutionary advancements in medicine, electronics, and robotics, promising a future where technology shrinks to unimaginable scales.

Applications in Medicine

The potential of miniaturization in medicine is vast and transformative. Miniature drills could revolutionize minimally invasive surgeries, allowing for more precise and targeted procedures with reduced recovery times. Imagine surgeons operating on delicate tissues with tools that are smaller than a human hair, minimizing collateral damage and improving patient outcomes.

- Microsurgical Procedures: Miniature drills can be used to perform complex microsurgical procedures, such as repairing damaged blood vessels or nerves, with unprecedented accuracy and control.

- Targeted Drug Delivery: Miniature drills could be used to create micro-channels in tissues, facilitating targeted drug delivery and improving the effectiveness of treatments.

- Biopsy and Tissue Sampling: Miniature drills could be used to extract tiny samples of tissue for analysis, enabling early diagnosis and personalized treatment plans.

Applications in Electronics

The miniaturization of electronics is a driving force behind the advancement of smartphones, wearable devices, and other cutting-edge technologies. Miniature drills could play a crucial role in the development of even smaller and more powerful electronic components, paving the way for a future where technology becomes increasingly integrated into our lives.

- Microelectronics Manufacturing: Miniature drills could be used to create intricate patterns and circuits on microchips, enabling the production of smaller, faster, and more energy-efficient processors.

- Nanoelectronics: As electronics continue to shrink, miniature drills could be used to manipulate individual atoms and molecules, opening up possibilities for quantum computing and other revolutionary technologies.

- 3D Printed Electronics: Miniature drills could be used to create 3D printed electronic circuits, enabling the development of flexible and customizable devices.

Applications in Robotics

Miniaturization is key to the development of advanced robotics, enabling the creation of smaller, more agile, and more versatile robots. Miniature drills could be used to create intricate mechanisms and components for robots that can navigate confined spaces, perform delicate tasks, and interact with the world in new ways.

- Microsurgery Robots: Miniature drills could be used to create surgical robots that can perform complex procedures with greater precision and control than human surgeons.

- Nanorobotics: Miniature drills could be used to create nanorobots that can travel through the human body, delivering drugs, repairing damaged cells, and performing other tasks at the molecular level.

- Swarm Robotics: Miniature drills could be used to create swarms of tiny robots that can work together to perform complex tasks, such as exploring dangerous environments or cleaning up hazardous waste.

The Future of Miniaturization

Miniaturization, the trend of shrinking devices and technologies, has been a driving force in innovation for centuries. From the invention of the microscope to the development of smartphones, miniaturization has enabled us to see the world in new ways, perform complex tasks with greater precision, and create devices that are more portable and accessible. As we continue to push the boundaries of what is possible at the nanoscale, the future of miniaturization promises to be even more transformative, impacting everything from medicine and manufacturing to energy and communication.

Potential Impact on Society

The impact of miniaturization on society is vast and far-reaching. As devices become smaller and more powerful, they will revolutionize many aspects of our lives, from the way we work and communicate to the way we treat diseases and manage our energy consumption.

- Medicine: Miniaturization will lead to the development of smaller, more precise medical devices, such as minimally invasive surgical tools, implantable sensors, and targeted drug delivery systems. These advancements will improve patient outcomes, reduce recovery times, and enhance the accuracy of diagnoses. For example, miniaturized robots could be used to perform complex surgeries with greater precision, while implantable sensors could monitor vital signs and alert doctors to potential health problems before they become serious.

- Manufacturing: Miniaturization will revolutionize manufacturing processes, enabling the creation of products with greater complexity and functionality. 3D printing at the nanoscale will enable the production of intricate components and devices with unprecedented levels of precision, leading to the development of new materials and products with enhanced properties. For instance, miniaturized 3D printers could be used to create custom-designed implants for patients, while nanoscale sensors could be integrated into everyday objects to monitor their performance and detect potential failures.

- Energy: Miniaturization will play a crucial role in the development of more efficient and sustainable energy technologies. Smaller, more powerful batteries will enable the creation of electric vehicles with longer ranges and more powerful devices that can run for longer periods without needing to be recharged. Miniaturized solar cells could be integrated into clothing, windows, and other surfaces, providing a source of clean energy that is readily available and easy to access. For example, miniaturized solar panels could be used to power homes and businesses, while nanotechnology could be used to develop more efficient and durable batteries for electric vehicles and other devices.

- Communication: Miniaturization will continue to drive the development of faster, more reliable, and more secure communication technologies. Smaller, more powerful chips will enable the creation of faster and more efficient computers and smartphones, while the development of new wireless communication technologies will enable us to connect to the internet and share information with greater speed and ease. For instance, miniaturized sensors could be used to monitor traffic flow and optimize traffic patterns, while nanotechnology could be used to develop new materials that can absorb and transmit light more efficiently, enabling the development of faster and more reliable optical fibers for data transmission.

Ethical Considerations

The development of increasingly smaller technologies raises a number of ethical considerations that must be carefully considered.

- Privacy: As miniaturized sensors and devices become more prevalent, there is a growing concern about the potential for privacy violations. For example, miniaturized cameras could be used to track people’s movements without their knowledge or consent, while implanted sensors could be used to monitor people’s health data without their permission. This raises questions about the balance between the benefits of miniaturization and the need to protect individual privacy.

- Security: Miniaturization also raises security concerns, as smaller devices can be more easily hacked or compromised. For example, miniaturized implants could be used to manipulate people’s behavior or access their personal information, while nanobots could be used to spread disease or sabotage critical infrastructure. It is important to develop security measures that can protect against these threats and ensure the responsible use of miniaturized technologies.

- Equity: The benefits of miniaturization may not be equally distributed, raising concerns about social and economic inequality. For example, access to advanced medical treatments based on miniaturization may be limited to those who can afford it, while the development of new technologies may lead to job displacement in certain sectors. It is important to ensure that the benefits of miniaturization are shared equitably and that everyone has access to the opportunities it creates.

Timeline of Miniaturization

Miniaturization has been a continuous process throughout history, with each advancement building upon the previous one. Here is a timeline outlining some of the key milestones in the development of miniaturization:

- 1590: Zacharias Janssen invents the compound microscope, allowing scientists to see objects that are too small to be seen with the naked eye.

- 1665: Robert Hooke publishes “Micrographia,” which contains detailed illustrations of microscopic objects, including the first known image of a cell.

- 1876: Alexander Graham Bell invents the telephone, marking the beginning of the era of electronic communication.

- 1907: Lee De Forest invents the triode vacuum tube, which revolutionizes radio communication and lays the foundation for the development of electronics.

- 1947: William Shockley, John Bardeen, and Walter Brattain invent the transistor, a device that replaces bulky vacuum tubes and opens the door for miniaturization in electronics.

- 1958: Jack Kilby invents the integrated circuit, a single chip that can contain multiple transistors and other electronic components.

- 1971: Intel releases the first microprocessor, a single chip that can perform the functions of a central processing unit (CPU).

- 1981: IBM releases the first personal computer, marking the beginning of the personal computer revolution.

- 1990s: The development of nanotechnology enables the manipulation of matter at the atomic and molecular level, opening up new possibilities for miniaturization.

- 2007: Apple releases the first iPhone, a smartphone that combines a mobile phone, a computer, and a multimedia player in a single device.

- 2010s: The development of 3D printing and other additive manufacturing technologies enables the creation of complex objects at the nanoscale, further driving miniaturization.

Man in new zealand 3d prints the worlds smallest working drill – This tiny drill is more than just a novelty; it represents a significant leap forward in miniaturization. It has the potential to revolutionize fields like medicine, electronics, and robotics, opening up new avenues for innovation and discovery. The future of miniaturization is bright, and this remarkable invention is just the beginning of what we can achieve with this groundbreaking technology.

A Kiwi bloke just 3D printed the world’s smallest working drill, proving that innovation can come from anywhere. It’s pretty wild, considering even big companies like BMW are reportedly making a big shift to electric cars, bmw reportedly making big shift to electric cars. Maybe this tiny drill is just the start of a whole new wave of miniaturized tech that’s about to blow our minds.

Standi Techno News

Standi Techno News