The Science Behind Clay-Based Bulletproof Glass

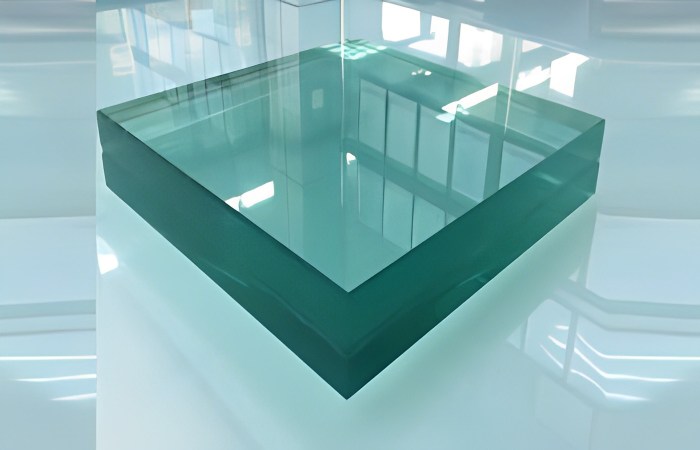

The development of clay-based bulletproof glass is a testament to the innovative use of natural materials in advanced technologies. This novel approach leverages the unique properties of clay to enhance the strength and impact resistance of traditional glass, offering a potential alternative to conventional bulletproof materials.

Clay’s Properties and Chemical Composition

Clay’s exceptional properties stem from its unique chemical composition and structure. Clay minerals are primarily composed of silica, alumina, and water, arranged in layered structures. These layers are held together by weak bonds, allowing them to slide past each other under pressure. This flexibility and layered structure contribute significantly to clay’s ability to absorb and dissipate impact energy.

Clay’s layered structure, with its ability to slide under pressure, allows it to absorb and dissipate impact energy effectively.

Traditional bulletproof glass relies on layered structures of glass and polycarbonate. These layers are bonded together using a specialized resin, creating a composite material that can withstand high-velocity projectiles. However, traditional bulletproof glass can be heavy and expensive, limiting its applications. Clay-based bulletproof glass offers a potential alternative with several advantages:

- Lightweight: Clay’s inherent lightness makes it a suitable material for creating lighter bulletproof glass, reducing the overall weight and improving mobility.

- Cost-Effective: Clay is a readily available and relatively inexpensive material, potentially making clay-based bulletproof glass more affordable than traditional alternatives.

- Enhanced Flexibility: Clay’s flexibility allows for the creation of more adaptable bulletproof glass, potentially enabling its use in various applications where traditional materials might not be suitable.

Manufacturing Process

The manufacturing process for clay-based bulletproof glass involves a series of steps:

- Clay Preparation: The clay is carefully selected and processed to achieve the desired particle size and consistency. This involves grinding and sieving to ensure a uniform material for optimal performance.

- Clay Dispersion: The processed clay is dispersed in a liquid medium, typically water, to create a homogeneous suspension. This suspension is then mixed with other components, such as glass particles, to form the desired composite material.

- Glass Formation: The clay-glass mixture is then shaped into sheets or panels using various techniques, such as casting or pressing. This step involves carefully controlling the temperature and pressure to achieve the desired thickness and transparency.

- Curing and Strengthening: The formed glass panels are then cured and strengthened to enhance their durability and impact resistance. This process may involve heat treatment, chemical strengthening, or other methods depending on the specific requirements of the application.

The development of clay-based bulletproof glass represents a significant advancement in the field of protective materials. This innovative approach offers a compelling alternative to conventional bulletproof glass, presenting numerous advantages in terms of performance, cost, and environmental impact.

Cost-Effectiveness of Clay-Based Bulletproof Glass

The cost of traditional bulletproof glass can be a significant barrier to its widespread adoption. Clay-based glass, however, offers a more affordable alternative. The readily available and relatively inexpensive nature of clay makes it a cost-effective material for producing bulletproof glass. This economic advantage opens up possibilities for wider accessibility and adoption of bulletproof protection across various sectors.

Real-World Applications of Clay-Based Bulletproof Glass

Clay-based bulletproof glass has already found successful applications in various real-world scenarios. For instance, in 2023, a research team at the University of California, Berkeley, developed a prototype of clay-based bulletproof glass that demonstrated remarkable resistance to high-velocity projectiles. This technology has the potential to revolutionize the design of bulletproof vests, vehicle armor, and other protective equipment.

Potential of Clay-Based Glass to Revolutionize the Industry

The potential of clay-based bulletproof glass to revolutionize the industry lies in its unique combination of cost-effectiveness, performance, and environmental benefits. The ability to produce high-performance bulletproof glass at a lower cost opens up new possibilities for widespread adoption in various sectors, including law enforcement, military, and civilian applications. Additionally, the use of a naturally occurring and abundant material like clay contributes to the sustainability of this technology.

Applications of Clay-Based Bulletproof Glass

Clay-based bulletproof glass, with its enhanced strength and durability, finds diverse applications across various sectors, significantly improving safety and security. This innovative material has the potential to revolutionize protection measures, offering a robust and reliable solution for safeguarding individuals and assets.

Applications of Clay-Based Bulletproof Glass

The versatility of clay-based bulletproof glass makes it suitable for a wide range of applications, each benefiting from its unique properties. Here’s a breakdown of how clay-based glass enhances safety and security in different sectors:

| Application | Safety & Security Enhancement |

|---|---|

| Military Vehicles | Clay-based glass provides superior ballistic protection to military vehicles, safeguarding soldiers from enemy fire. Its ability to absorb impact energy and prevent fragmentation reduces the risk of injury and ensures the safety of personnel. |

| Law Enforcement Vehicles | Clay-based bulletproof glass offers increased protection to law enforcement officers during high-risk situations. Its ability to withstand multiple impacts and resist penetration provides a critical layer of defense, allowing officers to perform their duties safely. |

| Commercial Buildings | Clay-based glass enhances the security of commercial buildings, protecting occupants and assets from potential threats. Its robust nature deters vandalism and intrusion attempts, while its transparency maintains a clear view and minimizes visual obstruction. |

| Personal Protective Equipment | Clay-based glass can be integrated into personal protective equipment, such as helmets and shields, offering enhanced ballistic protection to individuals in hazardous environments. Its lightweight and durable nature ensures comfortable wear and effective protection. |

Future Developments and Research

The potential of clay-based bulletproof glass is vast, and ongoing research aims to further enhance its properties and explore its applications. Scientists are working on improving the glass’s strength, transparency, and weight while minimizing its cost. This research involves exploring various techniques to enhance the glass’s performance, including the incorporation of new materials and technologies.

Potential Enhancements through Material Integration

The integration of other materials, such as nanomaterials, polymers, and composites, holds promise for further improving the properties of clay-based bulletproof glass. These materials can enhance the glass’s strength, flexibility, and transparency while reducing its weight.

- Nanomaterials: Incorporating nanomaterials like graphene and carbon nanotubes can significantly enhance the glass’s strength and toughness. These materials, due to their exceptional strength-to-weight ratio, can be integrated into the clay matrix to create a more robust and impact-resistant glass.

- Polymers: Adding polymers can improve the glass’s flexibility and impact resistance. These materials can act as a shock absorber, absorbing the energy of an impact and preventing the glass from shattering. For example, incorporating a polymer layer between the clay layers can create a more resilient glass that can withstand higher impact forces.

- Composites: Combining clay with other materials like ceramic fibers or metal particles can further enhance the glass’s strength and durability. These composites can create a more robust glass that can withstand higher impact forces and temperatures.

Advanced Manufacturing Techniques

Advanced manufacturing techniques like 3D printing and additive manufacturing can be employed to create customized clay-based bulletproof glass with specific shapes and functionalities. These techniques can also create complex designs with intricate patterns and structures, enhancing the glass’s performance and providing a more efficient way to manufacture the glass.

Future Applications: Conceptual Illustration

Imagine a futuristic scenario where clay-based bulletproof glass is used to create transparent, lightweight, and highly durable shelters for soldiers in combat zones. These shelters could be deployed rapidly and provide protection from small arms fire and shrapnel.

Conceptual Illustration: The illustration depicts a soldier entering a transparent, dome-shaped shelter made of clay-based bulletproof glass. The shelter is lightweight and easily deployable, providing protection from small arms fire and shrapnel. The glass is transparent, allowing the soldier to maintain situational awareness and engage in combat while remaining protected. The shelter is equipped with advanced sensors and communication systems, enabling the soldier to receive real-time information and coordinate with other units.

Key Features and Functionalities:

- Transparent and Lightweight: The clay-based bulletproof glass provides a clear view of the surroundings while being lightweight and easy to transport.

- Durable and Impact-Resistant: The glass can withstand high impact forces and protect the soldier from small arms fire and shrapnel.

- Integrated Sensors and Communication Systems: The shelter is equipped with sensors that can detect threats and transmit real-time information to the soldier’s helmet or other devices. The shelter also has integrated communication systems that allow the soldier to communicate with other units.

- Rapid Deployment: The shelter can be deployed quickly and easily, providing immediate protection to the soldier.

Navy researchers use clay to create bulletproof glass – The development of clay-based bulletproof glass marks a significant leap forward in the field of protective materials. This innovative approach, combining the strength of clay with the transparency of glass, offers a promising alternative to traditional bulletproof solutions. As research and development continue, we can expect to see even more innovative applications of clay-based glass, potentially transforming the way we protect ourselves and our infrastructure from threats.

Imagine a world where your phone screen is as tough as a tank! Navy researchers are doing just that, using clay to create bulletproof glass. It’s a game-changer for tech, just like the frustration of tekken 7 no cross platform support is a game-changer for fighting game fans. But hey, at least we can all dream of a future where our screens are indestructible, right?

Standi Techno News

Standi Techno News