The Rise of Reinforced Plastic Gears

The demand for lightweight, durable, and high-performance materials is surging across various industries, driven by the need for efficiency, sustainability, and improved performance. From automotive and aerospace to robotics and manufacturing, the quest for materials that can withstand demanding conditions while minimizing weight is paramount. Traditional plastic gears, though cost-effective and easily moldable, often fall short in terms of strength and wear resistance, especially when subjected to high loads, extreme temperatures, or prolonged use.

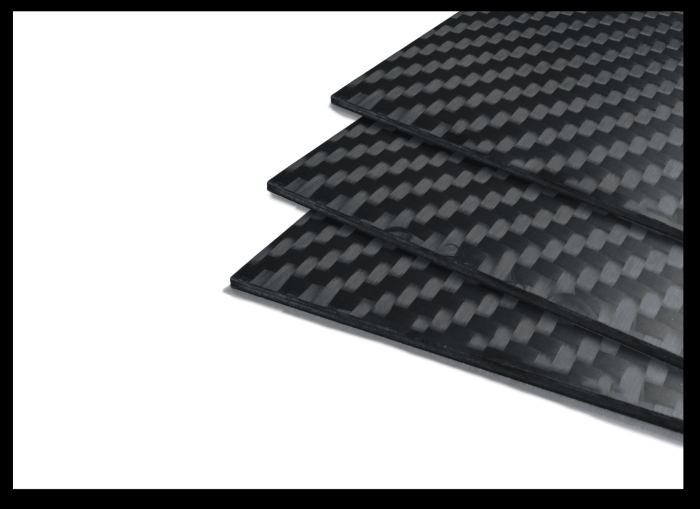

Carbon Fiber Reinforcement: A Solution for Enhanced Performance

To overcome these limitations, engineers are increasingly turning to carbon fiber reinforcement. Carbon fiber, known for its exceptional strength-to-weight ratio, stiffness, and resistance to fatigue, is a game-changer in material science. When integrated into plastic gears, it significantly enhances their mechanical properties, allowing them to handle heavier loads, operate at higher speeds, and endure longer without compromising their structural integrity.

Properties and Benefits of Carbon Fiber Reinforced Plastic Gears

Carbon fiber reinforced plastic (CFRP) gears are a relatively new innovation that offers a compelling alternative to traditional plastic and metal gears. They leverage the exceptional strength and stiffness of carbon fiber to create gears that are both lightweight and durable.

Mechanical Properties of CFRP Gears

CFRP gears exhibit superior mechanical properties compared to traditional plastic gears and even some metal gears. The strength and stiffness of carbon fiber, combined with the inherent properties of the resin matrix, give CFRP gears a unique combination of advantages.

Strength and Stiffness

Carbon fiber is renowned for its high tensile strength and stiffness. This translates directly into CFRP gears having exceptional resistance to bending and breaking under load. In fact, CFRP gears can withstand significantly higher loads than traditional plastic gears, while maintaining a lower weight. For example, CFRP gears can be used in applications where traditional plastic gears would fail prematurely, such as high-speed or high-torque applications.

Wear Resistance

CFRP gears exhibit excellent wear resistance, meaning they can withstand repeated contact and friction without experiencing significant wear and tear. This is due to the inherent hardness and abrasion resistance of carbon fiber. The resin matrix also plays a role in enhancing wear resistance by providing a smooth surface that reduces friction. As a result, CFRP gears can operate for longer periods without requiring replacement, which can lead to significant cost savings over the long term.

Comparison with Traditional Gears

CFRP gears offer a significant advantage over traditional plastic gears in terms of strength, stiffness, and wear resistance. While traditional plastic gears are often chosen for their low cost and ease of processing, they are generally weaker and more susceptible to wear and tear, limiting their use in demanding applications. CFRP gears bridge the gap between traditional plastic gears and metal gears, offering a compelling combination of strength, stiffness, and lightweight properties.

CFRP vs. Metal Gears

CFRP gears also offer advantages over metal gears in certain applications. For example, CFRP gears are significantly lighter than metal gears, which can be a critical factor in applications where weight is a major concern, such as aerospace and automotive industries. Additionally, CFRP gears are less prone to corrosion than metal gears, making them suitable for use in harsh environments. However, CFRP gears are generally more expensive to manufacture than metal gears, which can be a limiting factor in some applications.

Benefits of Using CFRP Gears

The exceptional properties of CFRP gears translate into a range of benefits for various applications. Here are some of the key advantages:

Weight Reduction

CFRP gears are significantly lighter than traditional metal gears, offering significant weight reduction in applications where weight is a critical factor. This weight reduction can lead to improved fuel efficiency in vehicles, increased payload capacity in aircraft, and reduced energy consumption in industrial machinery. For example, the use of CFRP gears in electric vehicles can contribute to an increase in range and efficiency.

Improved Efficiency

The lightweight nature of CFRP gears contributes to improved efficiency by reducing the inertia of rotating components. This means that less energy is required to start and stop the gear, resulting in smoother operation and reduced energy consumption. In applications where efficiency is paramount, such as wind turbines and electric motors, CFRP gears can offer a significant advantage.

Extended Lifespan

CFRP gears exhibit excellent wear resistance, which translates into a longer lifespan compared to traditional plastic gears. They can withstand repeated contact and friction without experiencing significant wear and tear, reducing the need for frequent replacements. This can lead to significant cost savings over the long term, particularly in applications where downtime is expensive.

Manufacturing Processes for CFRP Gears

Crafting carbon fiber reinforced plastic (CFRP) gears involves a range of specialized manufacturing techniques. Each method offers unique advantages and disadvantages, impacting factors like cost, production volume, and quality.

Pultrusion

Pultrusion is a continuous process that creates long, uniform profiles, including gears, by pulling a resin-impregnated fiber reinforcement through a heated die. This process excels in producing high-volume, consistent, and cost-effective CFRP gears.

Pultrusion is particularly suitable for applications requiring high strength-to-weight ratios, such as aerospace and automotive components.

- Advantages: High production rate, consistent quality, and relatively low cost per unit.

- Disadvantages: Limited design flexibility, primarily suited for simple geometries.

Injection Molding

Injection molding is a versatile process where thermoplastic resin is injected into a mold cavity, shaping it into a desired form. This method is widely used for creating CFRP gears with complex geometries and intricate designs.

- Advantages: High production volume, intricate designs, and precise dimensional control.

- Disadvantages: Higher initial tooling costs, potential for sink marks and warpage, and limitations with high-performance resins.

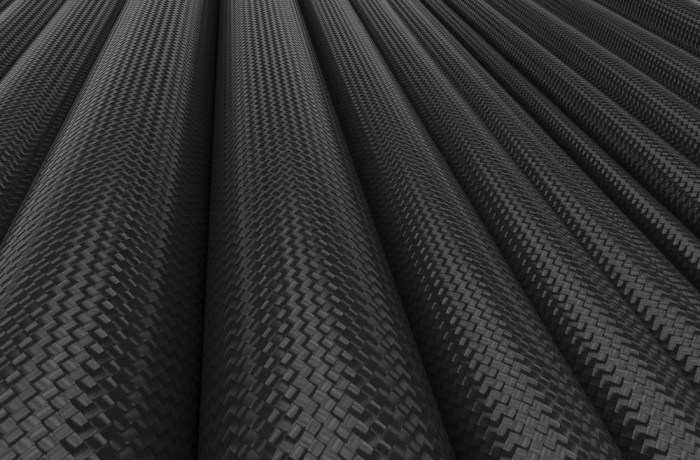

Filament Winding

Filament winding is a process where continuous fibers are wound onto a mandrel, forming a composite structure. This technique is particularly effective for creating CFRP gears with high strength and durability.

Filament winding is often used in applications requiring high strength and stiffness, such as pressure vessels and aerospace components.

- Advantages: High strength-to-weight ratio, excellent dimensional stability, and customization options.

- Disadvantages: Higher production cost, limited design complexity, and potential for fiber misalignment.

Companies and Technologies

Several companies specialize in the manufacturing of CFRP gears, employing various advanced technologies:

- Hexcel Corporation: A leading manufacturer of carbon fiber composites, Hexcel offers a range of pultrusion and filament winding technologies for CFRP gears.

- Toray Industries: A global leader in carbon fiber and composite materials, Toray provides advanced materials and manufacturing processes for high-performance CFRP gears.

- 3D Printing: Additive manufacturing, or 3D printing, is gaining traction in CFRP gear production, enabling the creation of complex geometries and customized designs.

Applications of CFRP Gears in Different Industries: Plastic Gears Reinforced With Carbon Fiber Could Be The Future

The exceptional properties of carbon fiber reinforced plastic (CFRP) gears, such as high strength-to-weight ratio, low inertia, and resistance to wear and tear, make them suitable for various industries where performance and efficiency are paramount. Their application extends beyond traditional metal gears, offering significant advantages in specific scenarios.

Automotive Industry

The automotive industry is constantly seeking ways to improve fuel efficiency and reduce emissions. CFRP gears can play a crucial role in achieving these goals.

- Reduced Weight: CFRP gears are significantly lighter than their metal counterparts, leading to reduced vehicle weight and improved fuel economy. This weight reduction also enhances acceleration and overall vehicle performance.

- Improved Fuel Efficiency: Lighter gears require less energy to rotate, resulting in lower fuel consumption. This is particularly beneficial in hybrid and electric vehicles where energy efficiency is critical.

- Noise Reduction: CFRP gears are inherently quieter than metal gears, contributing to a more comfortable driving experience.

However, the high cost of CFRP gears and the potential for damage from impact or high temperatures remain challenges for their widespread adoption in the automotive industry.

Aerospace Industry

The aerospace industry demands lightweight, durable, and reliable components. CFRP gears perfectly align with these requirements.

- Weight Savings: In aircraft, weight reduction translates to fuel savings and increased payload capacity. CFRP gears offer significant weight advantages over traditional metal gears, making them ideal for critical applications like landing gear and engine components.

- Enhanced Performance: The low inertia of CFRP gears allows for faster acceleration and deceleration, improving aircraft performance and maneuverability.

- Resistance to Corrosion: CFRP gears are highly resistant to corrosion, making them suitable for use in harsh environments like aircraft wings and engines.

Despite their benefits, the complex manufacturing processes and stringent quality control requirements for CFRP gears pose challenges in the aerospace industry.

Robotics Industry

Robotics heavily relies on precision, speed, and efficiency. CFRP gears can significantly enhance robotic performance.

- Increased Speed and Precision: The low inertia of CFRP gears allows for faster and more precise movements, improving robotic manipulation and assembly tasks.

- Reduced Wear and Tear: CFRP gears exhibit excellent wear resistance, ensuring prolonged operation and reduced maintenance requirements in demanding robotic applications.

- Enhanced Durability: CFRP gears can withstand high loads and vibrations, making them suitable for use in harsh industrial environments where robots operate.

The high cost and potential for damage from impact or excessive heat remain limitations for wider adoption of CFRP gears in robotics.

Consumer Goods Industry, Plastic gears reinforced with carbon fiber could be the future

CFRP gears are finding their way into consumer goods, particularly in applications where lightweight, durable, and aesthetically pleasing components are desired.

- Sporting Goods: CFRP gears are used in bicycles, golf clubs, and other sporting equipment to reduce weight and improve performance. Their strength and durability enhance the longevity and reliability of these products.

- Consumer Electronics: CFRP gears are increasingly employed in consumer electronics like cameras, drones, and wearable devices. Their lightweight design and aesthetic appeal contribute to the overall design and functionality of these products.

- Toys: CFRP gears are being used in high-end toys and model kits, offering durability and enhanced performance. Their lightweight nature also improves the handling and playability of these products.

The cost of CFRP gears remains a significant barrier for their widespread adoption in consumer goods, although advancements in manufacturing processes are gradually reducing this barrier.

Future Developments and Trends in CFRP Gear Technology

The field of CFRP gear technology is experiencing rapid advancements, driven by ongoing research and development efforts. This evolution promises to unlock a new era of high-performance, lightweight, and durable mechanical systems.

Advancements in CFRP Gear Properties and Performance

Research and development are constantly pushing the boundaries of CFRP gear properties and performance.

- Improved Fiber Architectures: Researchers are exploring innovative fiber architectures, such as 3D woven composites and hybrid fiber arrangements, to optimize strength, stiffness, and fatigue resistance in CFRP gears. These advanced architectures enhance load-bearing capacity and reduce the risk of premature failure.

- Tailored Resin Systems: The development of advanced resin systems with enhanced toughness, temperature resistance, and chemical compatibility is another key area of focus. These resins play a crucial role in bonding the fibers together and ensuring the overall integrity of the CFRP gear.

- Advanced Manufacturing Techniques: The adoption of advanced manufacturing techniques, such as automated fiber placement and resin transfer molding, enables the production of CFRP gears with complex geometries and precise fiber orientations. These methods contribute to improved performance and consistency in the final product.

Plastic gears reinforced with carbon fiber could be the future – The future of gears is undeniably intertwined with the advancement of carbon fiber reinforced plastic technology. As research and development continue to push the boundaries of material science, we can expect even more remarkable applications and innovations in the coming years. The integration of advanced composites and additive manufacturing techniques promises to further enhance the performance and versatility of CFRP gears, making them a cornerstone of the next generation of mechanical engineering marvels.

Imagine a future where gears are lighter, stronger, and more durable than ever before. That future might be closer than you think, thanks to the innovative use of plastic gears reinforced with carbon fiber. This breakthrough in materials science could revolutionize everything from automotive parts to robotics, and even impact the way we experience entertainment, like the upcoming NBC Apple TV app , which promises to deliver a seamless and immersive viewing experience.

With the potential to create more efficient and sustainable products, plastic gears reinforced with carbon fiber are poised to become the driving force behind a new era of innovation.

Standi Techno News

Standi Techno News