The Importance of Rare Earth Metals

Rare earth metals, despite their name, are not particularly rare in the Earth’s crust. However, their extraction and refinement are complex and costly processes, making them valuable and strategically important. These metals play a crucial role in modern technology, powering a wide range of industries and enabling advancements in various fields.

Diverse Applications Across Industries

Rare earth metals have diverse applications across various industries, contributing significantly to technological advancements. Their unique magnetic, electronic, and optical properties make them essential components in numerous products and technologies.

Examples of Key Technologies Reliant on Rare Earth Metals

- Electronics: Rare earth metals are crucial for the production of high-performance magnets used in smartphones, laptops, and other electronic devices. For example, neodymium magnets are widely used in hard drives, speakers, and electric motors, enabling smaller, more powerful, and efficient devices.

- Renewable Energy: Rare earth metals are essential for wind turbines and electric vehicles. Neodymium magnets are used in wind turbine generators, while dysprosium and terbium are used in permanent magnets for electric vehicle motors. These applications contribute to the development of clean and sustainable energy sources.

- Aerospace and Defense: Rare earth metals are used in aerospace and defense applications, including aircraft engines, missiles, and satellites. Their high strength-to-weight ratio and magnetic properties make them ideal for these demanding applications. For example, samarium-cobalt magnets are used in military aircraft and satellites for their high magnetic strength and resistance to demagnetization.

- Medical Devices: Rare earth metals are used in medical devices, such as MRI machines and lasers. Gadolinium is used as a contrast agent in MRI scans, while erbium is used in lasers for surgical procedures. These applications contribute to advancements in healthcare and diagnostics.

Challenges in Rare Earth Metal Extraction

Extracting rare earth metals is a complex and environmentally demanding process. Traditional methods, while effective, come with significant drawbacks, including environmental damage, social impacts, and high energy consumption.

Environmental Concerns

Traditional rare earth metal extraction methods are notorious for their environmental impact. The process involves mining, processing, and refining, each stage posing unique challenges.

- Mining: Open-pit mining, the primary method for extracting rare earth minerals, disrupts ecosystems, displaces wildlife, and generates large amounts of waste rock and tailings. This waste can contaminate water sources and soil, posing risks to human health and the environment.

- Processing: The processing of rare earth ores involves the use of harsh chemicals and acids, releasing toxic byproducts into the environment. These chemicals can leach into groundwater, contaminate air, and pose health risks to nearby communities.

- Refining: Refining rare earth metals often involves high-temperature processes that release greenhouse gases, contributing to climate change. The process also generates significant amounts of radioactive waste, which requires careful management to prevent environmental contamination.

Social Impacts

The extraction of rare earth metals can have significant social impacts on local communities.

- Land Displacement: Mining operations often require the displacement of local communities, disrupting their livelihoods and cultural practices. This can lead to social unrest and conflict.

- Health Risks: Exposure to toxic chemicals and dust during mining and processing can lead to health problems for workers and nearby residents. These health risks can include respiratory problems, skin diseases, and cancer.

- Resource Depletion: The extraction of rare earth metals is resource-intensive, and the depletion of these resources can have long-term consequences for the environment and economy.

High Energy Consumption

The extraction and refining of rare earth metals require significant energy input, contributing to greenhouse gas emissions.

- Mining and Processing: The mining and processing of rare earth ores are energy-intensive, requiring large amounts of electricity and fossil fuels. These activities contribute to carbon emissions.

- Refining: Refining rare earth metals involves high-temperature processes that require significant energy input. The energy used for refining often comes from fossil fuels, further contributing to carbon emissions.

Advancements in Extraction Efficiency

The extraction of rare earth metals is becoming more efficient due to the development of innovative technologies that address the challenges of traditional methods. These advancements are crucial for meeting the increasing demand for rare earth metals while minimizing environmental impact.

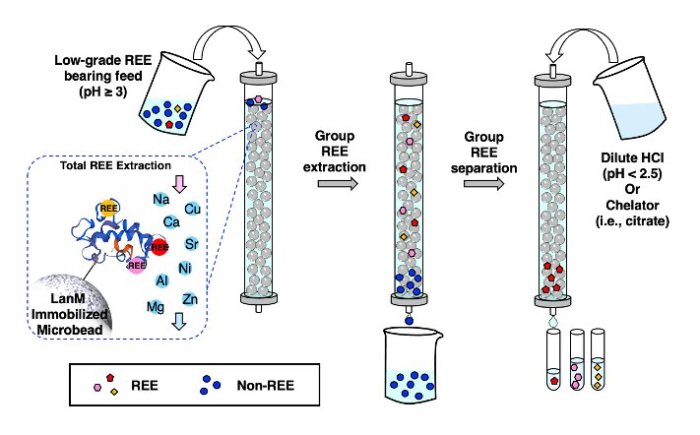

Bioleaching, Rare earth metals extraction gets more efficient

Bioleaching employs microorganisms to extract rare earth metals from ores. These microorganisms, often bacteria, can break down the ore and release the metals into solution. This method is particularly effective for low-grade ores and can be more environmentally friendly than traditional methods.

Bioleaching offers a sustainable alternative to conventional methods by using naturally occurring microorganisms to extract rare earth metals.

Hydrometallurgical Extraction

Hydrometallurgical extraction involves using aqueous solutions to dissolve and separate rare earth metals from ores. This method is becoming increasingly popular as it can be more efficient and environmentally friendly than traditional methods.

Hydrometallurgical extraction utilizes chemical reactions in aqueous solutions to selectively dissolve and recover rare earth metals from ores.

Solvent Extraction

Solvent extraction is a process that uses organic solvents to separate rare earth metals from other elements in solution. This method is highly effective for separating different rare earth metals from each other, leading to high-purity products.

Solvent extraction employs organic solvents to selectively extract and separate rare earth metals based on their chemical properties.

Ionic Liquid Extraction

Ionic liquids are salts that are liquid at room temperature. They offer unique properties that can be exploited for rare earth metal extraction. For example, ionic liquids can be used to selectively extract rare earth metals from complex mixtures, leading to high purity products.

Ionic liquid extraction leverages the unique properties of ionic liquids, such as their high polarity and tunable properties, to selectively extract and separate rare earth metals.

Impact of Efficient Extraction on Supply and Demand

The advancement of rare earth metal extraction techniques holds the potential to significantly alter the dynamics of supply and demand in this critical sector. Improved extraction efficiency can lead to a greater availability of these metals, impacting market prices, global trade, and the development of technologies reliant on rare earths.

Impact on Supply

Increased extraction efficiency can directly translate into a larger supply of rare earth metals. This can alleviate concerns about resource scarcity and potentially reduce the reliance on a limited number of producing countries. For instance, advancements in hydrometallurgical processes, such as solvent extraction and ion exchange, can enhance the recovery rate of rare earth elements from ores, thereby increasing the overall supply.

Technological Implications of Increased Rare Earth Metal Availability: Rare Earth Metals Extraction Gets More Efficient

The increased availability of rare earth metals, driven by efficient extraction methods, can significantly impact the advancement of various technologies. This abundance can unlock new possibilities for innovation and create a ripple effect across various sectors.

Potential for Developing New Technologies and Applications

A readily available supply of rare earth metals can act as a catalyst for the development of new technologies and applications. These materials are crucial components in many modern technologies, including:

- Electric Vehicles: Rare earth magnets are vital for electric vehicle motors, allowing for higher torque and efficiency. Increased availability could lead to more widespread adoption of electric vehicles, contributing to a greener transportation sector.

- Renewable Energy: Rare earth metals are used in wind turbines, solar panels, and energy storage systems. Their availability could accelerate the transition to a sustainable energy future.

- Electronics: Rare earth metals are essential for the production of smartphones, computers, and other electronic devices. Their availability could drive the development of more powerful and efficient devices.

- Aerospace and Defense: Rare earth metals are used in aircraft engines, satellites, and military equipment. Increased availability could lead to advancements in these sectors, enhancing performance and capabilities.

Role of Efficient Extraction in Ensuring a Sustainable Supply Chain for Rare Earth Metals

Efficient extraction is crucial for establishing a sustainable supply chain for rare earth metals. This involves minimizing environmental impact and maximizing resource recovery.

“Sustainable extraction practices are vital for ensuring the long-term availability of these critical materials.”

Here are some key aspects of sustainable extraction:

- Minimizing Environmental Impact: Efficient extraction methods can reduce waste generation, minimize water consumption, and limit air pollution, ensuring responsible resource utilization.

- Maximizing Resource Recovery: Advanced extraction techniques can recover a higher percentage of rare earth metals from ores, reducing the need for new mining operations and minimizing environmental disturbance.

- Recycling and Reuse: Promoting the recycling of rare earth metals from electronic waste and other sources can further enhance the sustainability of the supply chain, reducing dependence on new mining.

Rare earth metals extraction gets more efficient – The future of rare earth metals extraction is bright. With innovative technologies driving efficiency and sustainability, we can unlock the potential of these critical elements for a greener and more technologically advanced future. As the world embraces a cleaner and more sustainable path, the efficient extraction of rare earth metals will play a crucial role in powering our progress. It’s a win-win for technology, the environment, and the global economy.

While scientists are making strides in developing more efficient ways to extract rare earth metals, we’re also seeing improvements in our everyday tech. The latest update to OneNote for Android brings multi-window support and a new widget, making note-taking even more seamless. These advancements, both in resource extraction and user experience, are pushing us towards a future where technology and sustainability go hand in hand.

Standi Techno News

Standi Techno News