Scientists use x rays to help create better chocolate – Scientists Use X-rays to Create Better Chocolate – it sounds like something out of a sci-fi movie, right? But it’s actually a real-life application of cutting-edge technology in the world of chocolate. Imagine a world where chocolate is not only delicious but also perfectly textured and free of imperfections. That’s the promise of X-ray technology in the chocolate industry.

X-ray imaging allows scientists to peer deep into the heart of chocolate, revealing its intricate crystal structure, potential flaws, and even the secrets of its flavor development. By understanding these microscopic details, they can optimize the production process, creating chocolate that’s not only visually appealing but also a sensory delight.

The Science Behind Chocolate Crystallization

Chocolate, a beloved treat enjoyed by millions, owes its diverse textures and flavors to the intricate process of crystallization. Understanding the science behind chocolate crystallization is crucial for creating high-quality, delectable chocolate.

Types of Chocolate Crystals and Their Impact on Texture

The texture of chocolate is largely determined by the arrangement of its crystals. Different crystal forms, each with unique properties, influence the overall sensory experience.

- Form V: This form, characterized by small, needle-like crystals, produces a smooth, creamy texture. It’s commonly found in milk chocolate and is associated with a delicate melt-in-your-mouth sensation.

- Form VI: This form, characterized by larger, blocky crystals, results in a snappy, crisp texture. It’s often found in dark chocolate and contributes to its intense, bittersweet flavor.

The Role of X-Ray Diffraction in Analyzing Chocolate Crystal Structure

X-ray diffraction (XRD) is a powerful tool used to analyze the structure of crystalline materials, including chocolate. By shining X-rays onto a chocolate sample, scientists can observe the diffraction patterns created by the interaction of X-rays with the crystal lattice. These patterns provide valuable information about the size, shape, and arrangement of the crystals within the chocolate.

Comparing and Contrasting Chocolate Crystal Properties Using X-Ray Data

X-ray diffraction data allows scientists to compare and contrast the properties of different chocolate crystals. For example, Form V crystals, due to their smaller size, exhibit a higher density compared to Form VI crystals. This difference in density can influence the melting point and mouthfeel of the chocolate.

Additionally, X-ray diffraction can reveal information about the polymorphism of chocolate crystals. Polymorphism refers to the ability of a substance to exist in multiple crystalline forms. This information is crucial for optimizing the manufacturing process to achieve desired texture and flavor profiles.

X-ray Imaging for Chocolate Quality Control: Scientists Use X Rays To Help Create Better Chocolate

X-ray imaging has emerged as a powerful tool in the chocolate industry, enabling manufacturers to ensure the quality and safety of their products. By harnessing the penetrating power of X-rays, manufacturers can detect defects that are invisible to the naked eye, ensuring that only the finest chocolate reaches consumers.

Detecting Defects in Chocolate Bars, Scientists use x rays to help create better chocolate

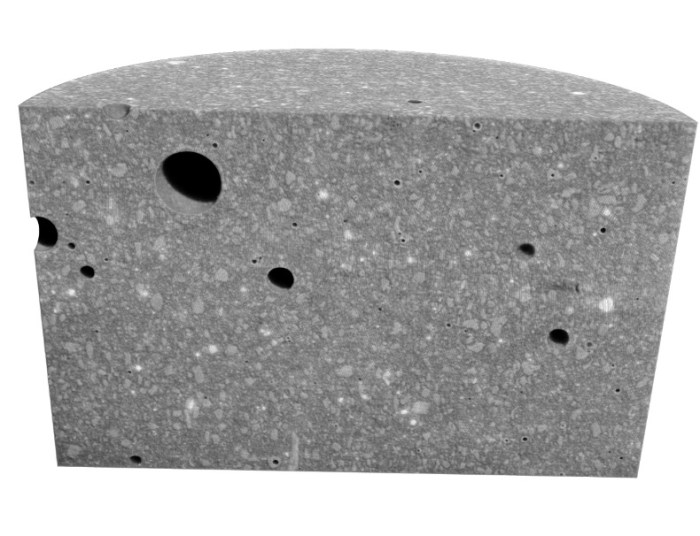

X-ray imaging plays a crucial role in identifying potential defects within chocolate bars. By passing X-rays through the chocolate, manufacturers can create detailed images that reveal internal structures and anomalies.

This technology allows for the detection of:

- Air Bubbles: Air bubbles can compromise the texture and appearance of chocolate. X-ray imaging can pinpoint these bubbles, enabling manufacturers to adjust production processes and eliminate them.

- Foreign Objects: Accidental contamination with foreign objects, such as pieces of metal, plastic, or even insects, can pose a serious safety hazard. X-ray imaging can effectively identify these contaminants, preventing them from reaching consumers.

- Cracks and Breakages: X-ray imaging can detect cracks and breakages within the chocolate bar that may not be visible on the surface. This allows manufacturers to identify and discard damaged bars, ensuring that only intact products are shipped.

Advantages of X-ray Technology for Chocolate Quality Control

X-ray imaging offers several advantages for quality control in chocolate production:

- Non-Destructive: Unlike traditional methods, X-ray imaging is non-destructive, meaning it does not damage the chocolate being inspected. This allows for efficient and thorough quality control without compromising the integrity of the product.

- High Sensitivity: X-ray imaging can detect even the smallest defects, ensuring a high level of accuracy and reliability in quality control. This helps maintain consistent quality across all batches of chocolate.

- Real-Time Inspection: X-ray imaging systems can be integrated into production lines, enabling real-time inspection of chocolate bars. This allows for immediate identification and removal of defective products, reducing the risk of contaminated chocolate reaching consumers.

- Improved Efficiency: X-ray imaging streamlines the quality control process, reducing the need for manual inspection and minimizing human error. This translates to increased efficiency and reduced production costs.

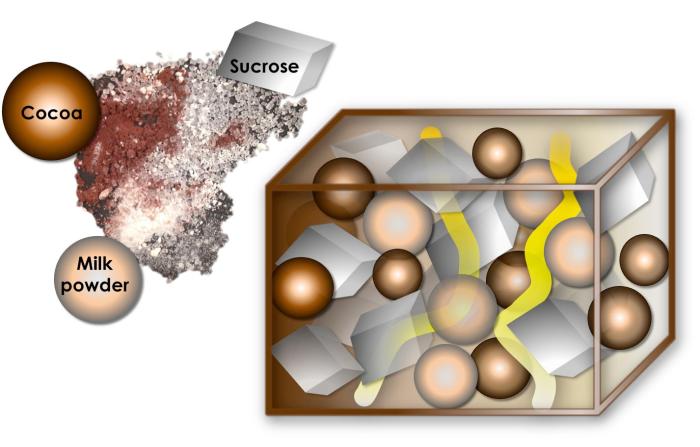

Analyzing Chocolate Composition

Beyond defect detection, X-ray imaging can also be used to analyze the composition of chocolate. By measuring the absorption of X-rays by different components of the chocolate, manufacturers can determine:

- Cocoa Content: The cocoa content of chocolate is a crucial factor influencing its flavor and nutritional value. X-ray imaging can accurately measure the cocoa content, ensuring consistency and compliance with industry standards.

- Sugar Content: X-ray imaging can also measure the sugar content of chocolate, allowing manufacturers to control the sweetness of their products. This helps cater to different consumer preferences and dietary needs.

- Fat Content: X-ray imaging can provide insights into the fat content of chocolate, which influences its texture and melting properties. This information can be used to optimize the formulation and production process.

The future of chocolate production is looking brighter than ever, thanks to the power of X-ray technology. As scientists continue to explore the potential of this innovative tool, we can expect even more delicious and innovative chocolate experiences. So, the next time you savor a piece of chocolate, remember the hidden science that’s making it even more delightful. And maybe, just maybe, you’ll see a glimpse of those X-rays working their magic behind the scenes.

Scientists are using X-rays to create the perfect chocolate bar, analyzing its crystal structure to ensure smooth melting and a rich flavor. But while they’re busy perfecting the ultimate chocolate experience, the next Destiny expansion will be the biggest content addition yet , promising to expand the game’s universe and offer hours of new gameplay. Just like the scientists are using technology to enhance chocolate, Destiny’s developers are using their skills to create a truly immersive gaming experience.

Standi Techno News

Standi Techno News