Siemens Electric Aircraft Motor: Siemens Electric Aircraft Motor Is Very Capable

The aviation industry is undergoing a dramatic transformation, driven by the urgent need to reduce its environmental footprint. At the forefront of this revolution is Siemens, a leading technology company that has developed an electric aircraft motor poised to redefine air travel. This innovative motor is not just a technological marvel; it represents a significant step towards a more sustainable future for aviation.

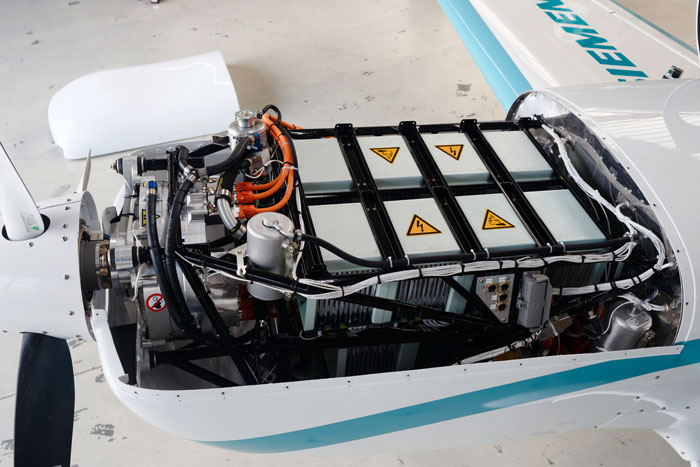

Key Technical Features and Innovations

Siemens’ electric aircraft motor is a testament to the company’s engineering prowess, incorporating a number of groundbreaking features. One of the most notable innovations is the motor’s high power density, which allows for compact design while delivering exceptional performance. This is achieved through the use of advanced materials and sophisticated cooling systems that enable the motor to operate at higher temperatures and speeds. Furthermore, the motor’s efficiency is significantly enhanced by its unique design, which minimizes energy losses and maximizes power output.

Comparison with Traditional Jet Engines

The Siemens electric aircraft motor offers a compelling alternative to traditional jet engines, demonstrating significant advantages in terms of efficiency, noise levels, and environmental impact. While jet engines rely on burning fossil fuels to generate thrust, electric motors harness the power of electricity, eliminating harmful emissions and contributing to a cleaner atmosphere. Additionally, electric motors are significantly quieter than jet engines, reducing noise pollution and enhancing the passenger experience. The efficiency of electric motors also translates into lower fuel consumption, resulting in substantial cost savings for airlines.

Efficiency and Fuel Consumption

Electric aircraft motors boast a significantly higher efficiency compared to traditional jet engines. This translates to lower fuel consumption, making them a more cost-effective option for airlines. For example, a recent study by the University of Nottingham estimated that an electric aircraft powered by Siemens’ motor could achieve a 50% reduction in fuel consumption compared to a conventional jet aircraft of similar size. This translates into substantial cost savings for airlines, as well as a significant reduction in carbon emissions.

Noise Levels and Environmental Impact

The Siemens electric aircraft motor offers a significant advantage in terms of noise levels. Electric motors are inherently quieter than jet engines, producing significantly less noise pollution. This is particularly beneficial for communities living near airports, as it reduces noise disturbance and improves the overall quality of life. Furthermore, the absence of emissions from electric motors significantly reduces the environmental impact of air travel, contributing to cleaner air and a healthier planet.

Applications and Potential of Electric Aircraft Motors

The development of electric aircraft motors represents a significant step towards a more sustainable and efficient future for aviation. Siemens’ electric aircraft motor, with its advanced design and capabilities, is poised to revolutionize various segments of the aviation industry. This technology holds the potential to transform the way we travel, transport goods, and even explore new frontiers.

Types of Aircraft Suitable for Electrification, Siemens electric aircraft motor is very capable

Electric aircraft motors are particularly well-suited for smaller aircraft, such as regional airliners, commuter planes, and cargo aircraft. This is because these aircraft typically operate on shorter routes and have lower power requirements compared to large commercial airliners. The smaller size and weight of electric motors make them ideal for integration into these types of aircraft, while their efficiency and reduced emissions offer significant advantages over traditional jet engines.

Potential Applications in Various Sectors

Commercial Aviation

Siemens’ electric aircraft motor technology can be applied in commercial aviation to enhance sustainability and efficiency. It can power smaller regional airliners, reducing fuel consumption and emissions. By electrifying these aircraft, airlines can contribute to a greener aviation sector and potentially reduce operating costs.

Regional Air Travel

Electric aircraft motors are particularly promising for regional air travel. They can power smaller commuter planes, connecting smaller cities and towns with major hubs. This can improve accessibility and connectivity for passengers in rural areas while also reducing environmental impact.

Cargo Transport

Electric aircraft motors can also be used for cargo transport, particularly for short-haul flights. This can improve efficiency and reduce emissions in the logistics industry.

Examples of Current or Planned Projects

Siemens is actively involved in various projects utilizing its electric aircraft motor technology. One notable example is the collaboration with Airbus on the E-Fan X project, which aims to develop a hybrid-electric aircraft for regional air travel. This project demonstrates the potential of electric propulsion systems for commercial aviation. Another example is the collaboration with the German Aerospace Center (DLR) on the “Green Flight Challenge,” which focuses on developing sustainable aircraft technologies, including electric propulsion. These projects showcase Siemens’ commitment to advancing electric aircraft motor technology and contributing to a more sustainable future for aviation.

Challenges and Opportunities in Electric Aircraft Development

The transition to electric aircraft, while promising, faces significant challenges and opportunities. The development and implementation of this technology require careful consideration of various factors, including battery technology, infrastructure, and regulatory hurdles. However, the potential benefits of electric aircraft, such as reduced emissions, lower operating costs, and improved noise levels, make this a worthwhile pursuit.

Battery Technology

Battery technology is a critical factor in electric aircraft development. Current battery technology limitations include energy density, weight, and charging time. The energy density of batteries needs to be significantly improved to power aircraft for longer distances. The weight of batteries is also a concern, as it affects the aircraft’s payload and overall efficiency. Charging time is another challenge, as it needs to be reduced to make electric aircraft commercially viable.

- Energy Density: Current battery technology does not offer sufficient energy density to power aircraft for long distances. The energy density of batteries needs to be significantly improved to enable electric aircraft to travel comparable distances to traditional aircraft. For example, the current battery technology in electric cars, while sufficient for short-distance travel, is not sufficient for long-haul flights.

- Weight: The weight of batteries is a major concern in electric aircraft development. Battery weight affects the aircraft’s payload and overall efficiency. A heavier aircraft requires more energy to fly, which reduces the aircraft’s range and increases operating costs.

- Charging Time: The time it takes to charge batteries is a critical factor in the commercial viability of electric aircraft. Currently, charging times are too long for practical use in commercial aviation. Rapid charging infrastructure is needed to make electric aircraft a viable alternative to traditional aircraft.

Infrastructure

The development of electric aircraft requires significant investments in infrastructure, including charging stations and maintenance facilities. The lack of adequate infrastructure is a major challenge for the widespread adoption of electric aircraft.

- Charging Stations: Electric aircraft require specialized charging stations with high power output. The development of a robust charging infrastructure, particularly at airports, is essential to support the widespread adoption of electric aircraft. The installation of these charging stations requires significant investment and coordination with airport authorities.

- Maintenance Facilities: Electric aircraft require specialized maintenance facilities with trained personnel to handle the unique aspects of electric propulsion systems. The development of these facilities will require investment and training programs to ensure the safe and efficient operation of electric aircraft.

Regulatory Hurdles

The adoption of electric aircraft also faces regulatory hurdles. Current regulations for aircraft certification and airworthiness need to be updated to accommodate the unique characteristics of electric aircraft.

- Aircraft Certification: Existing aircraft certification regulations are designed for traditional aircraft with internal combustion engines. The certification process for electric aircraft needs to be adapted to address the unique safety and performance requirements of electric propulsion systems. This includes rigorous testing and evaluation to ensure the safety and reliability of electric aircraft.

- Airworthiness: The airworthiness of electric aircraft needs to be demonstrated through rigorous testing and evaluation. The certification process should consider factors such as battery performance, motor reliability, and the impact of electric propulsion systems on aircraft stability and control.

Reduced Emissions

Electric aircraft offer significant potential for reducing greenhouse gas emissions. The use of electricity, which can be generated from renewable sources, can significantly reduce the carbon footprint of aviation.

- Environmental Impact: Electric aircraft powered by renewable energy sources can significantly reduce greenhouse gas emissions, contributing to a cleaner and more sustainable aviation industry. The reduction in emissions is particularly significant compared to traditional aircraft that rely on fossil fuels.

Lower Operating Costs

Electric aircraft have the potential to reduce operating costs compared to traditional aircraft. Electric motors are more efficient than internal combustion engines, resulting in lower fuel consumption and reduced maintenance costs.

- Fuel Costs: Electric aircraft eliminate the need for fossil fuels, reducing operating costs associated with fuel consumption. This cost reduction can be significant, especially as fuel prices fluctuate.

- Maintenance Costs: Electric motors are simpler and have fewer moving parts than internal combustion engines. This results in lower maintenance costs and reduced downtime.

Improved Noise Levels

Electric aircraft are significantly quieter than traditional aircraft, reducing noise pollution and improving the overall passenger experience.

- Noise Reduction: Electric motors operate much quieter than internal combustion engines, resulting in reduced noise pollution. This is particularly beneficial for communities near airports, where aircraft noise can be a significant nuisance.

Impact on the Aviation Industry

The adoption of electric aircraft has the potential to significantly impact the aviation industry. It could lead to new business models, job creation, and increased competition.

- New Business Models: The development of electric aircraft could lead to new business models in the aviation industry. For example, smaller airlines could use electric aircraft to open new routes and serve underserved markets.

- Job Creation: The development and production of electric aircraft will create new jobs in areas such as battery technology, electric propulsion systems, and aircraft maintenance.

- Increased Competition: The entry of new players into the aviation industry, driven by the development of electric aircraft, could increase competition and lead to innovation and improved efficiency.

Siemens’ Role in Shaping the Future of Aviation

Siemens is at the forefront of the electric aviation revolution, actively shaping the future of air travel with its commitment to sustainable and efficient solutions. Recognizing the environmental impact of traditional aviation, Siemens is dedicated to developing innovative electric aircraft technologies that will reduce emissions and pave the way for a cleaner, greener future.

Siemens’ Commitment to Sustainable Aviation

Siemens’ dedication to sustainable aviation is evident in its active involvement in developing electric aircraft technologies. The company has a long history of innovation in the aerospace industry, and it is now leveraging its expertise in electric motors, power electronics, and software to drive the transition to electric flight.

Siemens’ commitment to sustainable aviation is rooted in its belief that electric aircraft can significantly reduce emissions and contribute to a more sustainable transportation system. The company’s vision is to create a future where air travel is not only efficient but also environmentally friendly.

Siemens’ Collaborations in Electric Aviation

Siemens recognizes the importance of collaboration in accelerating the development of electric aircraft technologies. The company actively collaborates with other industry players and research institutions to advance the field. These collaborations involve sharing expertise, developing joint projects, and creating a network of partners committed to the same goals.

Siemens collaborates with a diverse range of partners, including aircraft manufacturers, research institutions, and technology providers. These collaborations allow Siemens to access cutting-edge technologies, share best practices, and accelerate the development of electric aircraft solutions.

- Aircraft Manufacturers: Siemens partners with aircraft manufacturers like Airbus and Embraer to develop electric propulsion systems for various aircraft types, including regional airliners, business jets, and even large passenger aircraft. These collaborations involve designing and integrating electric motors, power electronics, and software into aircraft systems, ensuring optimal performance and efficiency.

- Research Institutions: Siemens collaborates with leading research institutions, such as the German Aerospace Center (DLR) and the University of Stuttgart, to conduct research on electric aircraft technologies. These collaborations involve exploring new concepts, developing innovative solutions, and advancing the understanding of electric flight.

- Technology Providers: Siemens partners with technology providers specializing in areas like battery technology, power management, and software development to create a complete electric aircraft ecosystem. These collaborations ensure that Siemens has access to the latest advancements in these critical areas, enabling the development of high-performance and reliable electric aircraft systems.

Siemens’ Vision for the Future of Air Travel

Siemens envisions a future where air travel is powered by electricity, significantly reducing emissions and contributing to a more sustainable transportation system. The company believes that electric aircraft will play a crucial role in achieving this vision, offering numerous advantages over traditional aircraft.

“Siemens is committed to driving the development of electric aircraft technologies that will revolutionize the future of air travel. Our vision is to create a world where air travel is not only efficient but also environmentally sustainable.” – Siemens CEO

Siemens’ vision for the future of air travel is based on the following key principles:

- Reduced Emissions: Electric aircraft are significantly more efficient than traditional aircraft, producing significantly fewer emissions. This is due to the higher efficiency of electric motors and the use of renewable energy sources to generate electricity.

- Improved Noise Levels: Electric aircraft are significantly quieter than traditional aircraft, reducing noise pollution and improving the overall quality of life in communities near airports.

- Increased Efficiency: Electric aircraft are designed to be more efficient than traditional aircraft, offering improved performance and reduced operating costs. This will make air travel more affordable and accessible to a wider range of people.

- Enhanced Reliability: Electric aircraft are designed to be more reliable than traditional aircraft, with fewer moving parts and a simplified propulsion system. This will improve safety and reduce maintenance costs.

Siemens electric aircraft motor is very capable – The Siemens electric aircraft motor is a testament to the potential of electric aviation to revolutionize the industry. From regional air travel to cargo transport, the possibilities are vast. As we move towards a more sustainable future, Siemens is paving the way for a quieter, cleaner, and more efficient air travel experience. The future of aviation is electric, and Siemens is at the forefront of this exciting evolution.

Siemens’ electric aircraft motor is a game-changer, offering powerful and efficient performance. But even the most advanced technology can have its hiccups, just like the infamous replacement Note 7 handset problems that plagued Samsung. Thankfully, Siemens has learned from past mistakes and is dedicated to ensuring their electric motors are as reliable as they are powerful.

Standi Techno News

Standi Techno News