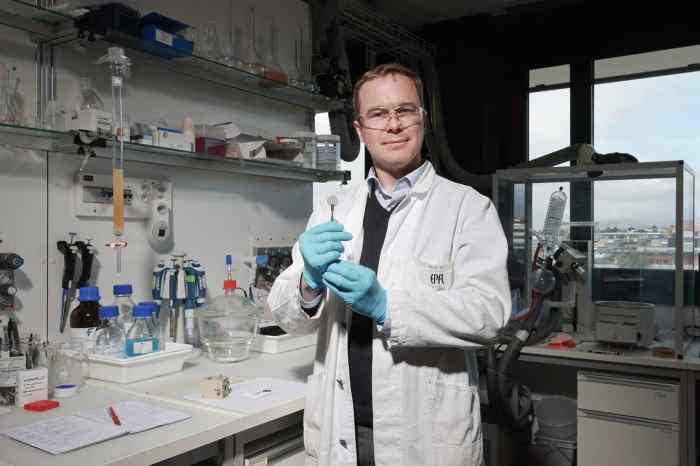

Solar Rig Design

The design of a solar rig for hydrogen fuel production from seawater is a complex endeavor that necessitates careful consideration of various factors, including the rig’s structure, energy generation, and hydrogen production processes. The rig’s design should prioritize efficiency, durability, and sustainability, while minimizing environmental impact.

Solar Panel Selection and Efficiency

The selection of solar panels is crucial for maximizing the conversion of sunlight into electricity. Different types of solar panels, such as monocrystalline, polycrystalline, and thin-film, offer varying efficiencies and cost considerations.

- Monocrystalline solar panels, known for their high efficiency and long lifespan, are typically more expensive than other types. These panels have a single crystal silicon structure, resulting in higher energy conversion rates.

- Polycrystalline solar panels are composed of multiple silicon crystals, leading to lower efficiency compared to monocrystalline panels. However, they are more cost-effective and widely used in solar applications.

- Thin-film solar panels are manufactured by depositing a thin layer of semiconductor material onto a substrate. They offer flexibility and lightweight properties but generally have lower efficiency than crystalline panels.

The efficiency of solar panels is measured as the percentage of sunlight converted into electricity. Typical solar panel efficiencies range from 15% to 20%, but advancements in technology are continuously improving these rates.

Solar Rig Schematic

The solar rig can be envisioned as a floating platform equipped with solar panels, electrolyzers, and hydrogen storage tanks.

- Solar Panels: Large arrays of solar panels, mounted on the rig’s deck, capture sunlight and convert it into electrical energy. The size and type of solar panels would depend on the desired hydrogen production capacity.

- Electrolyzers: These devices use electricity to split water molecules into hydrogen and oxygen gases. Electrolyzers are typically housed within the rig, near the solar panels.

- Hydrogen Storage Tanks: The produced hydrogen gas is stored in high-pressure tanks for later use. The storage capacity depends on the anticipated demand for hydrogen fuel.

The solar panels are connected to the electrolyzers, which in turn are connected to the hydrogen storage tanks. This arrangement ensures a continuous flow of electricity from the solar panels to the electrolyzers for hydrogen production.

Materials and Properties, Solar rig harvest hydrogen fuel ocean

The construction of the solar rig requires various materials, each with specific properties.

| Material | Properties | Application |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant, high strength-to-weight ratio | Rig frame, solar panel mounting structures, storage tank components |

| Stainless Steel | High strength, corrosion resistance, durability | Electrolyzer components, piping, structural supports |

| Fiberglass | Lightweight, corrosion-resistant, high tensile strength | Rig hull, deck panels, storage tank insulation |

| Polyvinyl Chloride (PVC) | Durable, water-resistant, flexible | Piping for seawater intake, hydrogen gas transportation |

| Titanium | High corrosion resistance, biocompatible, high strength | Electrolyzer electrodes, high-pressure components |

The choice of materials is guided by factors such as weight, strength, corrosion resistance, and compatibility with seawater and hydrogen gas.

Hydrogen Production

The production of hydrogen fuel from seawater using electrolysis is a promising approach to decarbonizing the energy sector. Electrolysis involves using electricity to split water molecules into hydrogen and oxygen. This process is particularly attractive for a solar rig, as it can leverage the abundant solar energy to power the electrolysis process.

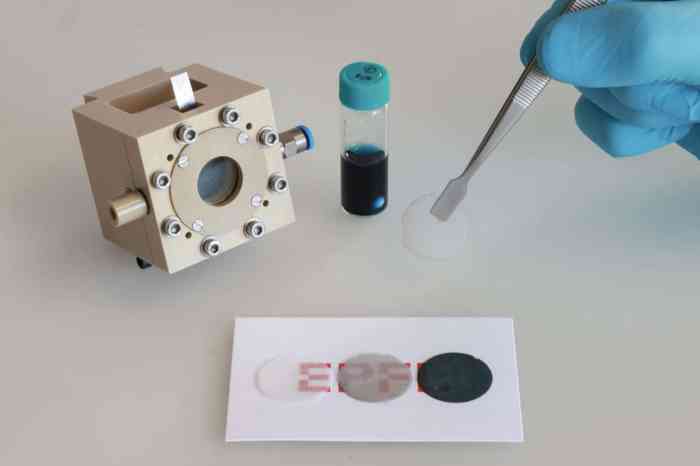

Electrolysis Process

Electrolysis is a process that uses an electric current to drive a non-spontaneous chemical reaction. In the context of hydrogen production, this involves splitting water molecules into hydrogen and oxygen gas. The process occurs in an electrolyzer, which consists of two electrodes immersed in an electrolyte solution. The electrodes are typically made of a catalytic material, such as platinum or nickel, which facilitates the chemical reactions.

The chemical reactions involved in the electrolysis of water are:

At the cathode (negative electrode): 2H+ + 2e– → H2

At the anode (positive electrode): 2H2O → O2 + 4H+ + 4e–

The overall reaction is: 2H2O → 2H2 + O2

Types of Electrolyzers

Different types of electrolyzers are available, each with its own advantages and disadvantages in terms of efficiency, cost, and operating conditions.

The efficiency of an electrolyzer is measured by its energy conversion efficiency, which is the ratio of the energy content of the produced hydrogen to the electrical energy consumed.

Alkaline Electrolyzers

Alkaline electrolyzers are the most mature and widely used type of electrolyzer. They use a potassium hydroxide (KOH) or sodium hydroxide (NaOH) electrolyte solution and operate at a relatively low pressure (around 2-3 bar). Alkaline electrolyzers are known for their high reliability and low cost, but they have lower efficiency compared to other types of electrolyzers.

Proton Exchange Membrane (PEM) Electrolyzers

PEM electrolyzers use a proton exchange membrane (PEM) as the electrolyte, which allows protons to pass through but blocks the passage of electrons. They operate at higher pressures (around 5-10 bar) and temperatures (around 80°C) compared to alkaline electrolyzers. PEM electrolyzers offer higher efficiency and faster response times, making them suitable for applications requiring high purity hydrogen.

Solid Oxide Electrolyzers (SOECs)

SOECs use a solid oxide ceramic material as the electrolyte, which operates at high temperatures (around 800°C). This high operating temperature allows SOECs to achieve high efficiency and can even be used for co-electrolysis, where carbon dioxide is also split into carbon monoxide and oxygen. However, SOECs are still under development and face challenges in terms of cost and durability.

Challenges and Limitations

While electrolysis offers a promising path for hydrogen production, several challenges and limitations need to be addressed:

* Energy Consumption: Electrolysis is an energy-intensive process, and the efficiency of the process depends on the type of electrolyzer used.

* Electrolyte Stability: Seawater contains dissolved salts and impurities that can affect the performance and lifetime of the electrolyzer.

* Corrosion: The corrosive nature of seawater can damage the electrolyzer components, particularly the electrodes.

* Scaling: Scaling can occur on the electrodes due to the presence of dissolved minerals in seawater, reducing the efficiency of the electrolysis process.

These challenges require further research and development to optimize the electrolysis process for seawater applications.

Oceanographic Considerations: Solar Rig Harvest Hydrogen Fuel Ocean

Deploying solar rigs in the ocean for hydrogen production requires careful consideration of the marine environment. Optimizing the location and design of these rigs is crucial to maximize hydrogen production efficiency while minimizing environmental impact.

Ideal Ocean Locations

The ideal location for deploying solar rigs for hydrogen production will depend on a variety of factors, including sunlight intensity, water temperature, and the presence of strong ocean currents. Areas with high solar irradiance and low cloud cover are preferable.

- Regions with abundant sunlight, such as the tropics and subtropics, are ideal for solar energy harvesting.

- Areas with moderate water temperatures, around 20-25°C, are generally suitable for hydrogen production as they provide a balance between optimal water temperature for electrolysis and minimizing the risk of fouling and corrosion.

- The presence of strong ocean currents can be beneficial for cooling the solar panels and for distributing the generated hydrogen, but it can also pose challenges for anchoring and stability of the rigs.

Impact of Oceanographic Factors on Efficiency

Oceanographic factors, such as ocean currents, salinity, and water temperature, can significantly impact the efficiency of hydrogen production.

- Ocean Currents: Strong ocean currents can increase the rate of heat transfer from the solar panels, thereby improving their efficiency. However, strong currents can also pose challenges for anchoring and stability of the rigs.

- Salinity: The salinity of seawater can impact the efficiency of electrolysis, as it can lead to corrosion of the electrodes. Therefore, it is important to use materials that are resistant to corrosion in seawater. Furthermore, the desalination of seawater for electrolysis can be an energy-intensive process, requiring additional energy input.

- Water Temperature: The temperature of the seawater can affect the efficiency of the electrolysis process. Higher water temperatures can lead to higher energy consumption and lower efficiency. Conversely, lower water temperatures can result in slower reaction rates, also reducing efficiency. Therefore, maintaining a suitable water temperature is crucial for optimal hydrogen production.

Environmental Impacts

The deployment of solar rigs in the ocean can have both positive and negative environmental impacts.

- Positive Impacts: Solar rigs can contribute to the reduction of greenhouse gas emissions by replacing fossil fuels with renewable hydrogen energy. They can also provide a platform for monitoring and studying the ocean environment. The presence of the rigs can create artificial reefs, attracting marine life and promoting biodiversity.

- Negative Impacts: Solar rigs can disrupt marine habitats and cause damage to ecosystems. The construction and deployment of these rigs can release pollutants into the water. The rigs can also create noise pollution, potentially affecting marine life. There is also a risk of accidental spills or leaks of hydrogen or other chemicals, which can have severe consequences for the marine environment.

Environmental Regulations and Considerations

Operating solar rigs in marine environments requires adherence to strict environmental regulations and considerations.

| Regulation/Consideration | Description |

|---|---|

| Marine Mammal Protection Act (MMPA) | Prohibits the harassment, hunting, capture, or killing of marine mammals, including noise pollution and habitat disturbance. |

| Endangered Species Act (ESA) | Protects endangered and threatened species, including their habitats. Solar rigs must be designed and operated to avoid harming or disturbing these species. |

| Clean Water Act (CWA) | Regulates the discharge of pollutants into navigable waters. Solar rigs must comply with water quality standards and minimize the release of pollutants. |

| National Environmental Policy Act (NEPA) | Requires federal agencies to consider the environmental impacts of their actions. Solar rig projects must undergo an environmental impact assessment before construction and deployment. |

| International Maritime Organization (IMO) | Sets international standards for the safety and security of maritime transport. Solar rigs must comply with IMO regulations regarding navigation, safety, and environmental protection. |

Storage and Transportation

Storing and transporting hydrogen fuel from the solar rig to shore presents unique challenges, but several promising technologies are being explored to overcome these obstacles. Efficient and cost-effective storage and transportation are crucial for making hydrogen fuel a viable energy source.

Hydrogen Storage Technologies

The storage of hydrogen is a critical aspect of its utilization as a fuel. Different methods are used to store hydrogen, each with its advantages and disadvantages.

- Compressed Hydrogen: This method involves storing hydrogen gas at high pressures, typically between 350 and 700 bar. This method is relatively simple and cost-effective, but it requires robust storage tanks and can be bulky.

- Liquid Hydrogen: This method involves cooling hydrogen to its boiling point of -252.87 °C, which significantly reduces its volume. However, liquefaction requires significant energy and specialized infrastructure.

- Hydrogen Storage Materials: This method utilizes materials that can absorb and store hydrogen in a solid form. These materials, such as metal hydrides or carbon-based materials, offer high storage density and can be more compact than compressed or liquefied hydrogen. However, they require research and development to improve their performance and cost-effectiveness.

Transportation Challenges and Infrastructure

Transporting hydrogen fuel from the solar rig to shore involves overcoming several challenges.

- Long Distances: The distance between the solar rig and shore can be considerable, requiring efficient transportation methods.

- Safety: Hydrogen is highly flammable, requiring robust safety measures during transportation.

- Infrastructure Development: Existing infrastructure for transporting and distributing hydrogen is limited, necessitating significant investment in pipelines, tankers, and other transport systems.

Infrastructure for Hydrogen Transportation

Several infrastructure options are being considered for transporting hydrogen fuel from the solar rig to shore.

- Pipelines: Pipelines offer a cost-effective and efficient way to transport large volumes of hydrogen over long distances. However, pipeline construction can be expensive and requires extensive land acquisition.

- Tankers: Tankers are used to transport hydrogen in liquid or compressed form. This method is suitable for smaller volumes and can be more flexible than pipelines.

- Hydrogen Fuel Cells: Hydrogen fuel cells can be used to power vehicles, ships, and other transportation systems, reducing reliance on fossil fuels. However, widespread adoption of hydrogen fuel cells requires significant infrastructure development.

Applications of Ocean-Derived Hydrogen

The production of hydrogen fuel from seawater using solar rigs presents a promising avenue for decarbonizing various sectors, particularly the maritime industry. This approach offers a sustainable and scalable solution for meeting the growing demand for clean energy.

Decarbonizing the Maritime Industry

Hydrogen fuel holds immense potential for decarbonizing the maritime industry, which currently relies heavily on fossil fuels. Ocean-derived hydrogen can be used to power ships and vessels, reducing greenhouse gas emissions and improving air quality.

- Fueling Ships and Vessels: Hydrogen can be used as a direct fuel for ships and vessels, replacing traditional fossil fuels like diesel and bunker oil. This transition would significantly reduce emissions of carbon dioxide, sulfur dioxide, and nitrogen oxides, contributing to cleaner air and a healthier marine environment.

- Hybrid Propulsion Systems: Hydrogen can be integrated into hybrid propulsion systems, combining it with existing technologies like electric motors and batteries. This approach allows for greater flexibility and efficiency, optimizing fuel consumption and reducing emissions.

- Bunker Fuel Replacement: Hydrogen can serve as a drop-in replacement for bunker fuel, the heavy oil used in large ships. This transition would significantly reduce emissions from the shipping industry, which accounts for a significant portion of global maritime emissions.

Challenges and Opportunities for Integration

Integrating ocean-derived hydrogen into existing energy systems presents both challenges and opportunities.

- Infrastructure Development: Building the necessary infrastructure for hydrogen production, storage, transportation, and distribution is crucial. This includes developing hydrogen pipelines, refueling stations, and other supporting infrastructure.

- Technology Advancement: Further advancements in hydrogen production technologies, such as electrolysis and fuel cell systems, are essential for improving efficiency and reducing costs. This includes research and development of new materials and processes for more efficient hydrogen generation and storage.

- Policy and Regulatory Frameworks: Establishing clear policies and regulatory frameworks for the production, transportation, and use of hydrogen is vital. This includes setting standards for safety, emissions, and environmental impact.

- Public Awareness and Acceptance: Raising public awareness about the benefits of hydrogen fuel and addressing concerns about its safety and environmental impact is crucial for widespread adoption.

Economic Benefits of Ocean-Derived Hydrogen

The production of hydrogen from seawater using solar rigs offers significant economic benefits, including:

- Job Creation: The development and deployment of ocean-based hydrogen production facilities will create new jobs in various sectors, including engineering, construction, operation, and maintenance.

- Reduced Energy Costs: By reducing reliance on fossil fuels, hydrogen can help lower energy costs for industries and consumers. This can be particularly beneficial for the maritime industry, where fuel costs are a significant expense.

- Increased Energy Security: By diversifying energy sources, hydrogen production can enhance energy security and reduce dependence on imported fossil fuels.

- New Market Opportunities: The development of a hydrogen economy will create new market opportunities for businesses involved in hydrogen production, storage, transportation, and distribution.

Solar rig harvest hydrogen fuel ocean – The development of solar rigs for harvesting hydrogen fuel from the ocean represents a significant step towards a cleaner, more sustainable energy future. This technology holds immense potential to decarbonize various industries, including transportation, power generation, and manufacturing. By utilizing the abundant resources of the ocean and the power of the sun, solar rigs offer a promising solution to address the global energy challenges we face. As we continue to explore and refine this technology, we can look forward to a future powered by clean, renewable energy derived from the ocean’s vast resources.

Imagine a solar-powered rig harvesting hydrogen fuel from the ocean, a futuristic vision powered by renewable energy. This ambitious project might sound like something straight out of a sci-fi movie, but it’s actually a real possibility thanks to advances in technology. It’s a reminder that innovation is everywhere, even in the realm of personal assistants like Cortana, which Microsoft is bringing to iOS and Android devices here.

Just like Cortana can adapt to different platforms, so too can our energy solutions evolve to meet the challenges of a changing world. The future of energy is bright, and it might just be powered by the sun and the sea.

Standi Techno News

Standi Techno News