Safety Concerns and User Responsibility

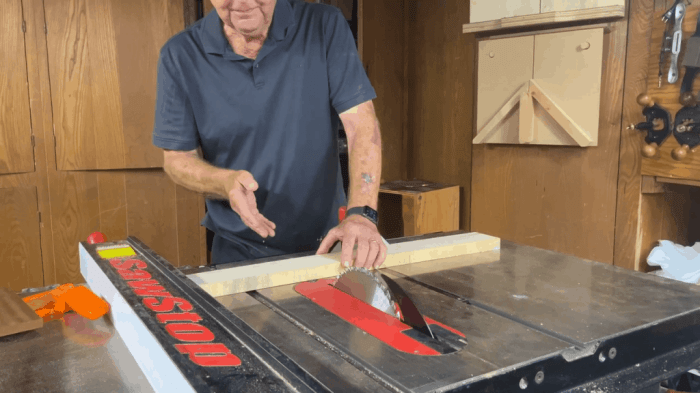

Operating a table saw can be dangerous, especially if it is not handled with care. The table saw is a powerful tool that can cause serious injury if it is not used correctly. Therefore, it is essential to understand the potential hazards associated with a table saw and to take appropriate safety precautions.

Safety Precautions

It is essential to prioritize safety when operating a table saw. Here are some important precautions to take:

- Always wear safety glasses to protect your eyes from flying debris.

- Use a push stick to keep your hands away from the blade.

- Never reach across the blade while it is running.

- Make sure the blade is sharp and properly aligned.

- Use a riving knife to prevent kickback.

- Keep your work area clean and free of clutter.

- Never operate a table saw while under the influence of alcohol or drugs.

User Responsibility

The user is ultimately responsible for ensuring the safe operation of a table saw. This responsibility includes:

- Inspecting the saw before each use to ensure that it is in good working order.

- Maintaining the saw according to the manufacturer’s instructions.

- Using the saw only for its intended purpose.

- Following all safety precautions.

Table Saw Maintenance

Regular maintenance is crucial for ensuring the safe and efficient operation of a table saw. Here are some essential maintenance tasks:

- Blade Maintenance: Regularly inspect the blade for damage, such as chips, cracks, or dullness. Replace or sharpen the blade as needed. Ensure the blade is securely mounted on the arbor and that the arbor nut is properly tightened.

- Motor and Electrical System: Check the motor for any signs of damage or overheating. Ensure all electrical connections are secure and that the power cord is in good condition. If you notice any issues, consult a qualified electrician.

- Dust Collection System: Regularly clean the dust collection system to prevent dust buildup. Ensure the dust collection bag or container is empty and that the dust collection system is working properly.

- Other Components: Inspect the fence, miter gauge, and other components for any signs of damage or wear. Replace or repair any damaged parts as needed.

Potential Causes of the Drop

A table saw dropping during operation can be a dangerous and unpredictable event. Understanding the potential causes of this issue is crucial for preventing accidents and ensuring the safety of users. The most common culprits include mechanical failures, design flaws, and improper installation or maintenance.

Mechanical Failures

Mechanical failures can lead to the saw dropping if the components responsible for supporting the saw blade and motor assembly become compromised. This could be due to wear and tear, fatigue, or improper installation.

- Faulty Bearings: Bearings are essential for smooth and reliable operation of the saw. Worn-out or damaged bearings can lead to excessive vibration and instability, eventually causing the saw to drop.

- Broken or Worn-Out Mounting Bolts: The bolts that secure the saw to the base or stand can become loose or break due to repeated use or improper torque. This can result in the saw becoming detached and falling.

- Defective Brackets or Supports: The brackets and supports that hold the saw blade and motor assembly in place can weaken or fail due to fatigue or manufacturing defects. This can lead to the saw tilting or dropping.

Consequences of the Drop

The sudden and forceful impact of a table saw dropping onto a user’s flesh can result in a range of injuries, from minor cuts and bruises to severe crush injuries and even amputation. The severity of the injury depends on several factors, including the weight of the saw, the height from which it falls, and the area of the body impacted.

The consequences of a table saw drop can be devastating, leading to significant physical pain, disability, and long-term complications.

Severity of Injuries

The severity of injuries resulting from a table saw drop can vary widely.

- Minor Injuries: These may include superficial cuts, bruises, and lacerations. While these injuries are typically treatable with first aid and may heal quickly, they can still cause pain and discomfort.

- Severe Injuries: These can include deep cuts, bone fractures, nerve damage, and crush injuries. Such injuries often require immediate medical attention and may result in permanent disability.

- Amputation: In the most severe cases, a table saw drop can lead to the amputation of a limb. This is a life-altering event that can have a profound impact on a person’s ability to work and live independently.

Long-Term Complications, This table saw will drop the moment it comes into contact with flesh

Even after initial treatment, injuries caused by a table saw drop can lead to long-term complications, such as:

- Chronic Pain: Nerve damage and tissue trauma can lead to persistent pain that may require ongoing pain management.

- Infections: Open wounds are susceptible to infection, which can be difficult to treat and may lead to further complications.

- Limited Mobility: Bone fractures and nerve damage can impair mobility and range of motion, affecting a person’s ability to perform everyday tasks.

- Psychological Impact: The trauma of a table saw drop can have a significant psychological impact, leading to anxiety, depression, and post-traumatic stress disorder (PTSD).

Impact on Daily Life

The consequences of a table saw drop can significantly impact a person’s ability to work and live a normal life.

- Work Disability: Depending on the severity of the injury, a person may be unable to return to their previous job or may require significant accommodations to continue working.

- Loss of Independence: Severe injuries can make it difficult to perform everyday tasks such as dressing, bathing, and cooking, leading to a loss of independence and requiring assistance from others.

- Financial Strain: Medical expenses, lost wages, and rehabilitation costs can place a significant financial burden on individuals and their families.

- Emotional Distress: The physical and emotional pain associated with a table saw drop can be overwhelming, leading to emotional distress, relationship problems, and social isolation.

Prevention and Mitigation Strategies

Preventing a table saw from dropping during operation is paramount to ensuring user safety and minimizing potential hazards. Regular inspections, proper maintenance, and prompt action in case of a drop are essential to mitigate risks.

Regular Inspections and Maintenance

Regular inspections and maintenance are crucial to ensure the table saw’s structural integrity and prevent potential drops.

- Inspect the saw’s base and support structure: Look for any signs of cracks, warping, or loose bolts. These can indicate structural weakness and a potential for the saw to drop.

- Check the mounting bolts and screws: Ensure all bolts and screws are tight and secure. Loose fasteners can cause the saw to become unstable and prone to dropping.

- Examine the saw’s motor mount: Ensure the motor mount is securely attached to the base and the motor itself is properly secured. A loose motor mount can lead to vibrations and instability, increasing the risk of a drop.

- Lubricate moving parts: Regularly lubricate moving parts, such as bearings and slides, to prevent friction and wear. This helps maintain the saw’s smooth operation and reduces the risk of a sudden drop.

- Replace worn or damaged parts: If any parts show signs of wear or damage, replace them promptly. Using worn or damaged parts can compromise the saw’s structural integrity and increase the risk of a drop.

Steps to Take in Case of a Table Saw Drop

In the event of a table saw drop, it’s essential to react quickly and safely to minimize potential injuries.

- Stop the saw immediately: Cut off the power supply to the saw as quickly as possible. Do not attempt to operate the saw if it has dropped.

- Assess the situation: Carefully evaluate the extent of the drop and any potential damage to the saw or surrounding area. Do not attempt to move the saw until it has been inspected and deemed safe.

- Contact a qualified technician: If the saw has dropped, it’s crucial to have it inspected by a qualified technician. They can assess the damage, repair or replace any damaged parts, and ensure the saw is safe for operation.

- Do not attempt to repair the saw yourself: Unless you are a qualified technician, do not attempt to repair the saw yourself. Improper repairs can worsen the problem and increase the risk of further drops or other accidents.

Legal and Ethical Considerations: This Table Saw Will Drop The Moment It Comes Into Contact With Flesh

The potential for a table saw to drop and cause injury raises significant legal and ethical concerns. Manufacturers, retailers, and users all have responsibilities to ensure the safety of this powerful tool.

Legal Implications of a Table Saw Dropping

The legal implications of a table saw dropping and causing injury can be significant, potentially leading to lawsuits and substantial financial penalties. Manufacturers, retailers, and users can all be held liable for injuries resulting from a defective product or negligence.

- Product Liability: Manufacturers can be held liable for defective products under product liability laws. If a table saw drops due to a design flaw, manufacturing defect, or inadequate safety features, the manufacturer could be sued for negligence or strict liability.

- Negligence: If a retailer fails to adequately inspect or warn about potential safety hazards associated with a table saw, they can be held liable for negligence.

- User Negligence: Users can also be held liable for injuries if they fail to follow safety instructions or use the table saw in a negligent manner.

Ethical Responsibilities of Manufacturers and Retailers

Manufacturers and retailers have an ethical responsibility to prioritize the safety of their customers. This includes:

- Designing Safe Products: Manufacturers should design table saws with safety features that minimize the risk of dropping, such as robust stands, secure mounting mechanisms, and clear warnings about potential hazards.

- Thorough Testing: Manufacturers should rigorously test their products to ensure they meet safety standards and perform as intended.

- Clear Instructions: Retailers should provide clear and comprehensive instructions on the safe operation and maintenance of table saws.

- Proper Warnings: Both manufacturers and retailers should provide clear and conspicuous warnings about the potential hazards associated with using a table saw.

Legal and Ethical Obligations of Users and Manufacturers

Users and manufacturers have both legal and ethical obligations related to table saw safety.

- User Obligations:

- Follow Instructions: Users must read and follow all safety instructions provided by the manufacturer.

- Proper Maintenance: Users are responsible for regularly inspecting and maintaining their table saws to ensure they are in safe working order.

- Safe Operation: Users must operate the table saw safely and avoid any actions that could increase the risk of the saw dropping.

- Manufacturer Obligations:

- Design Safety: Manufacturers have a legal and ethical obligation to design table saws that are inherently safe and minimize the risk of dropping.

- Quality Control: Manufacturers should implement rigorous quality control measures to ensure that their products meet safety standards and are free from defects.

- Post-Sale Support: Manufacturers should provide adequate post-sale support, including repair services and safety information, to users.

This table saw will drop the moment it comes into contact with flesh – The weight of a table saw dropping on a user’s flesh is a stark reminder of the importance of safety in woodworking. It’s a cautionary tale that should be etched into the minds of every operator, prompting them to prioritize safety and take every precaution. While the risk of this happening may seem small, the consequences are far too great to ignore. By embracing a culture of safety, we can ensure that woodworking remains a passion, not a potential tragedy.

It’s like that table saw, you know? The moment it touches flesh, it’s game over. And just like that, the hype around the 2017 iPhone’s latest Samsung OLED screen faded, replaced by the stark reality of a scratched display. The allure of innovation quickly fades when confronted with the harsh realities of everyday use. So yeah, that table saw, it’s a good reminder to be careful with your tech, too.

Standi Techno News

Standi Techno News